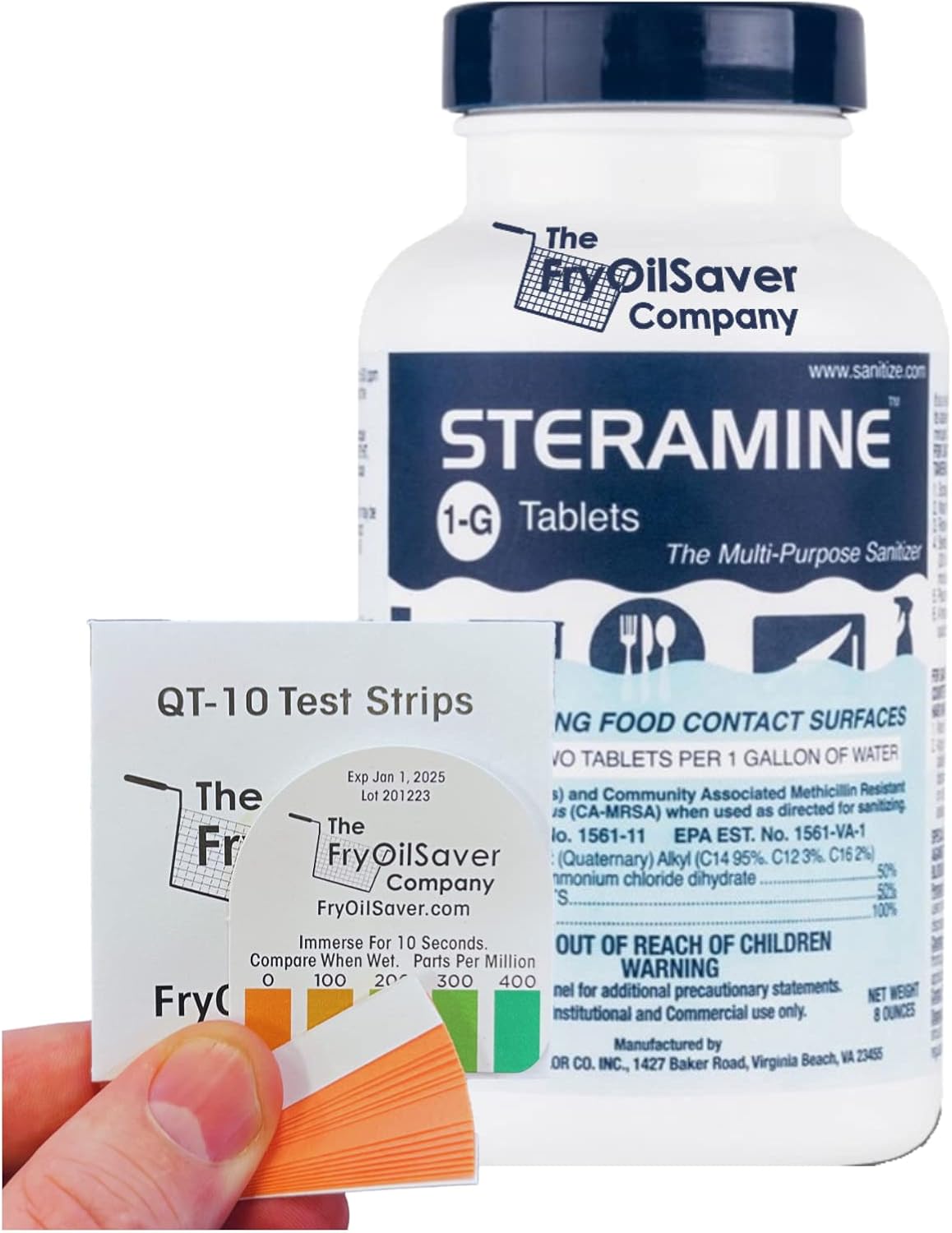

Steramine Sanitizer Tablets with QT-10 Test Strips, 150 Count

$12.95

Steramine sanitizer tablets with QT-10 test strips make it simple to mix, test, and trust your food-contact sanitizer. Drop 1 tablet in 1 gallon of warm water to make about 200 ppm quat, keep the surface wet for 1 minute, then air dry with no rinse. The kit includes 150 tablets and 15 Hydrion QT-10 strips that read 0 to 400 ppm in 10 seconds, so you can verify concentration before service or an inspection.

Description

If you run a busy kitchen, you already know that the right sanitizer saves time and keeps inspectors happy. The Steramine Sanitizer Tablet with 15 QT-10 Test Strips, Multi-Purpose Sanitizing Tablet for Food-Contact Surfaces, Kitchen, Restaurant, Steramine Sanitizer Tab for Food Service by FryOilSaver, 150 Tab, is a compact, pre-measured way to mix a food-service sanitizer at the right strength and verify it on the spot. One tablet per gallon typically makes a 200 parts per million quaternary solution, and the included QT-10 strips read 0 to 400 parts per million so you can confirm compliance in seconds.

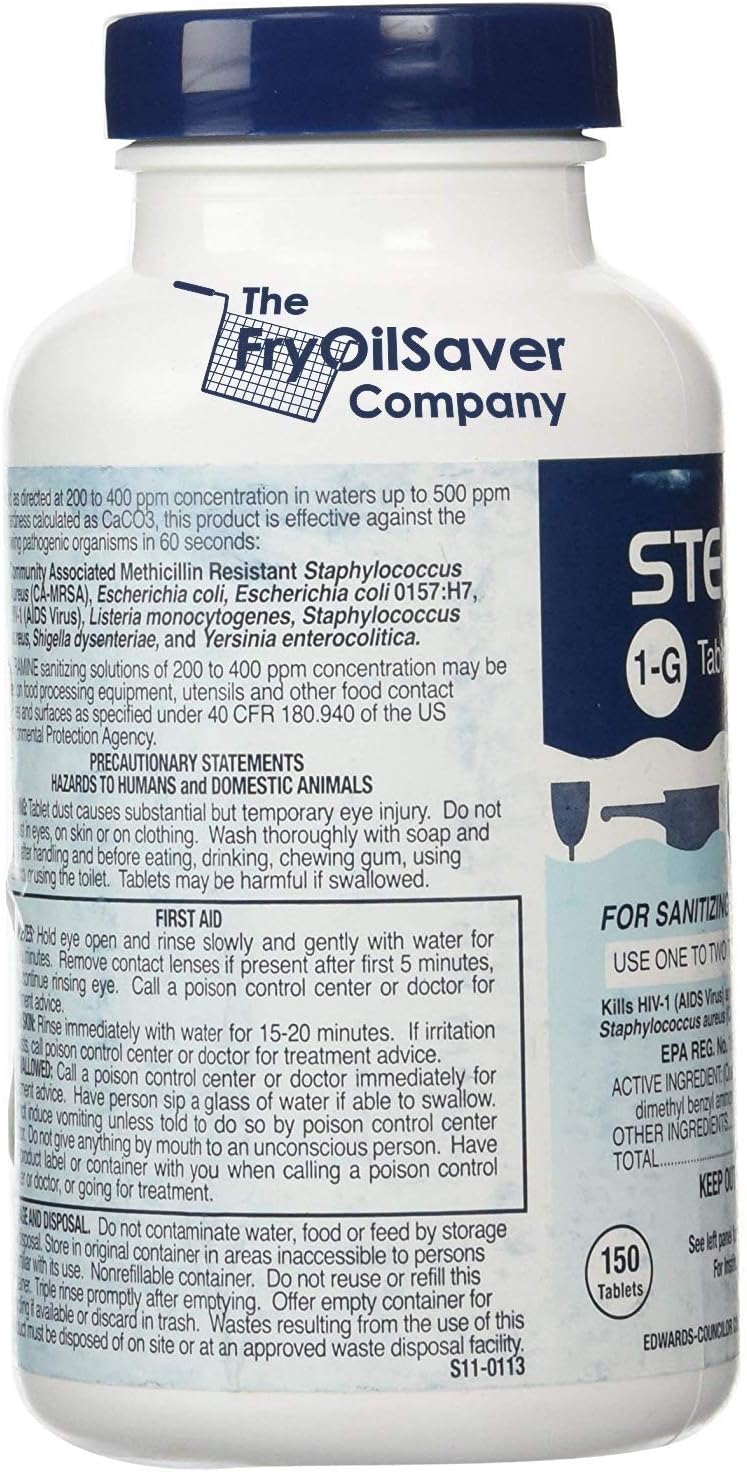

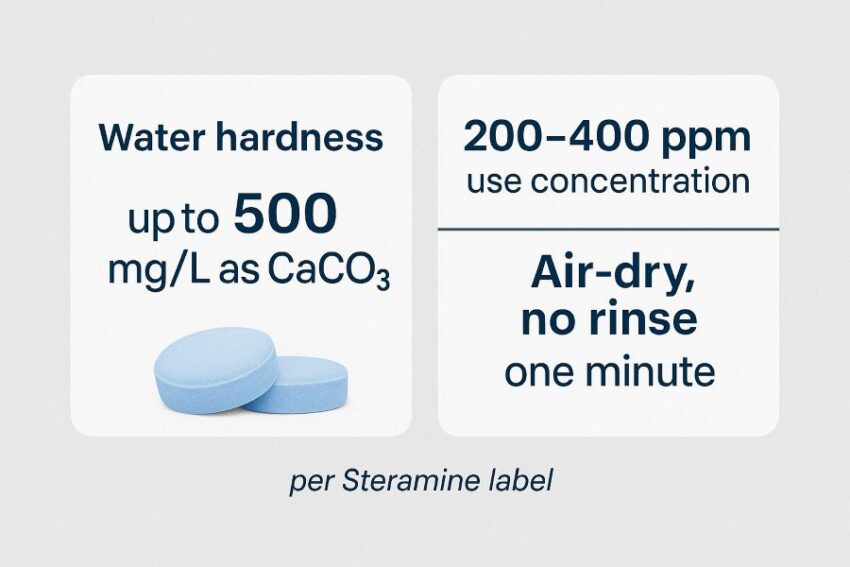

Behind that simplicity is real regulatory muscle. Steramine 1-G is an EPA-registered sanitizer from Edwards-Councilor, Reg. No. 1561-11, labeled for sanitizing food-contact equipment and utensils when mixed to 200 to 400 parts per million quaternary ammonium. That means you are working with a product that aligns with U.S. public health sanitizing criteria when used as directed.

Key Customer Benefits

- Inspector-ready results, without extra rinsing. When mixed correctly, Steramine sanitizer tablets create a no-rinse food-contact solution that needs only one minute of wet contact time. The EPA master label states to “allow surface to remain wet for at least one minute… Do not rinse or wipe,” which streamlines clean-as-you-go routines during service.

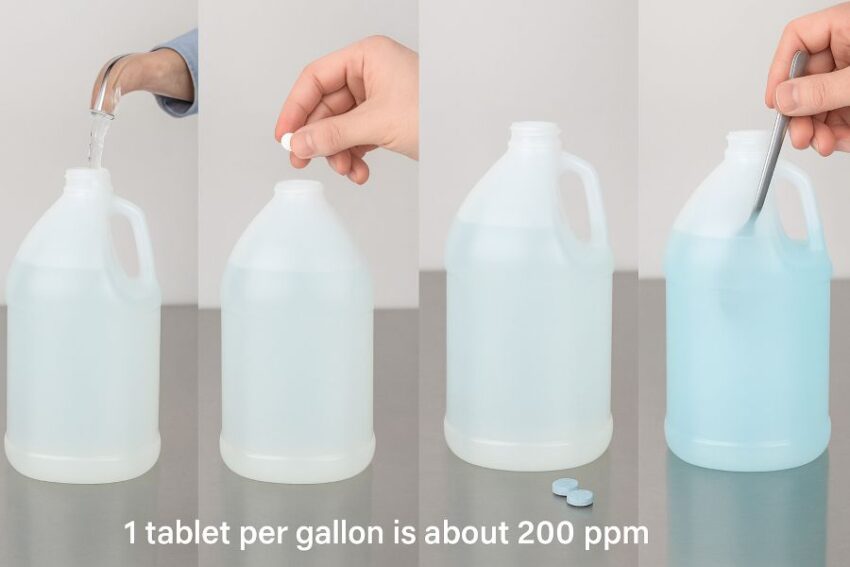

- Consistent, foolproof mixing every time. One tablet per gallon makes about 200 parts per million quaternary sanitizer, and two tablets make about 400 parts per million. That pre-measured dosing removes guesswork and helps you hit code-compliant ranges with ease.

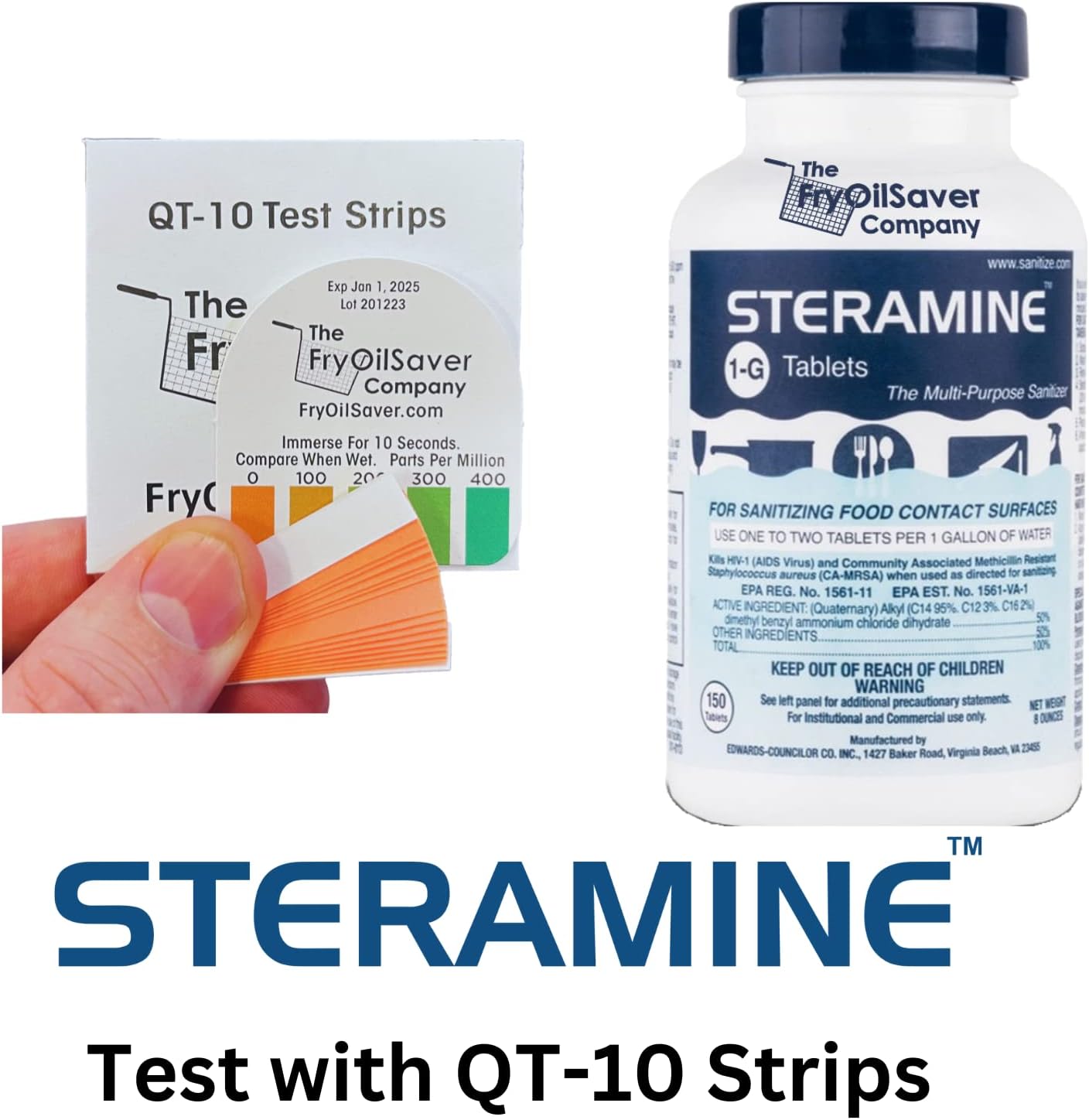

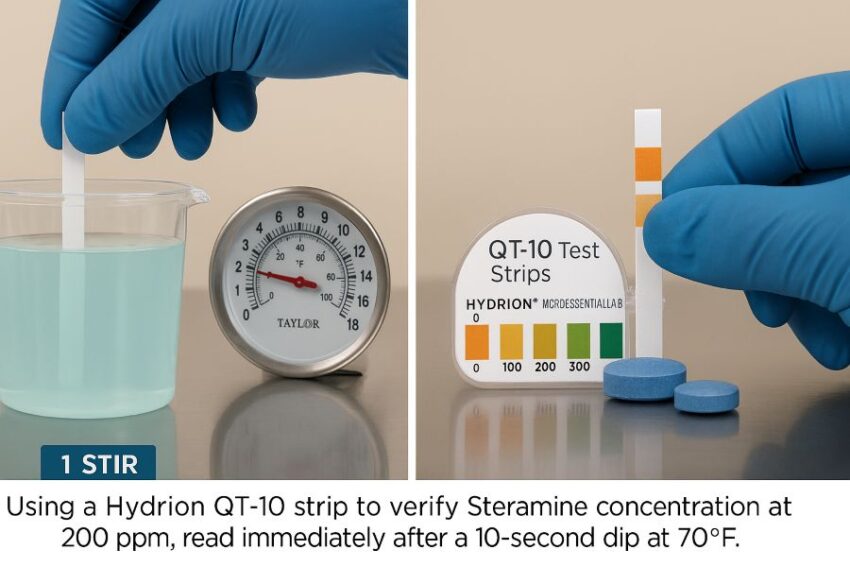

- Instant verification with QT-10 test strips. The included Hydrion QT-10 quaternary test strips read 0 to 400 parts per million. Dip for ten seconds, then match the color to confirm your bucket or spray bottle is on target before an inspection or a rush.

- Aligned with the FDA Food Code expectations. The Food Code requires proper sanitizer concentration, minimum temperature for quats, and having test kits on hand. Steramine solutions fit that framework when used as labeled, including use in water up to 500 milligrams per liter hardness.

- Kitchen-friendly on materials and senses. Quaternary ammonium sanitizers are generally non-corrosive and non-staining on stainless steel and plastics, and they are usually odorless, which makes them easier on staff and front-of-house areas than chlorine.

- Reliable performance in real-world water. The Steramine label specifies efficacy at 200 to 400 parts per million in waters up to 500 parts per million hardness and a one-minute contact time, so you get dependable sanitizing even if your facility has moderately hard water.

- Backed by an EPA-registered claim set. Used as directed, Steramine achieves a five-log reduction standard for sanitization and lists organisms such as Listeria monocytogenes and E. coli on the label, giving you confidence that your sanitizer choice is up to the job.

Product Description

What this product is

Steramine sanitizer tablets are EPA-registered quaternary ammonium, or “quat,” tablets from Edwards-Councilor that are formulated specifically for sanitizing food-contact equipment, utensils, and surfaces in food service.

The Steramine 1-G label specifies one tablet at 1.5 grams per gallon for about 200 parts per million, or two tablets per gallon for about 400 parts per million. Surfaces must stay visibly wet for at least one minute, then drain and air dry with no rinse. That is the key no-rinse claim operators like, because it saves time after the wash and rinse steps.

The bundle you are looking at includes 150 tablets and fifteen Hydrion QT-10 quaternary test strips. The QT-10 papers read 0 to 400 parts per million when you dip for ten seconds and compare to the color chart, which makes it easy to confirm your bucket or spray bottle before an inspection.

How it works

Quats are cationic surfactants. Their positive charge is attracted to microbial cell membranes, which disrupts the membrane and causes leakage of vital cell contents. In practical kitchen terms, that means a correctly mixed quat solution reduces bacteria on a clean surface to safe levels within the labeled contact time. That is the difference between cleaning and sanitizing. Cleaning removes soils. Sanitizing, at the right concentration and contact time, knocks down remaining microbes.

Two things make this kit work smoothly in day-to-day service. First, the tablets are pre-measured, so staff drop them into warm water, wait a few minutes for complete dissolve, and they are at code-appropriate strength without guesswork. Second, the included QT-10 strips let you verify concentration at the sink and on wiping-cloth buckets, which is what the FDA Food Code expects when it says a test kit that accurately measures sanitizer concentration shall be provided and used.

What makes it effective and different

For food-contact sanitizing, Steramine 1-G is labeled at 200 to 400 parts per million and one minute of wet contact. The label also specifies performance in water up to 500 milligrams per liter hardness, which helps in many cities where water is moderately hard. If you have struggled to keep chlorine buckets consistent, you will appreciate that quat solutions are not as volatile in routine kitchen conditions, and they are typically easier on stainless steel and surfaces than chlorine, which is more pH and temperature sensitive and can be corrosive.

Regulatory alignment matters. The Steramine label references 40 CFR 180.940, which is the federal tolerance exemption that allows certain quat actives to be used on food-contact surfaces when mixed to the end-use concentrations listed on the label. In other words, when you prepare and use the solution as directed, you are operating inside a well defined public-health framework that health inspectors recognize.

Product Specifications

| Spec | Details |

|---|---|

| Product type | Quaternary ammonium food-contact surface sanitizer tablets for institutional and commercial use |

| Bundle contents | 1 bottle of Steramine 1-G tablets and 15 Hydrion QT-10 quaternary test strips |

| Tablet weight | 1.5 grams per tablet |

| EPA registration | EPA Reg. No. 1561-11 |

| Active ingredient | Alkyl dimethyl benzyl ammonium chloride dihydrate. Formula listed as C14 95 percent, C12 3 percent, C16 2 percent. Active 50 percent of tablet by weight |

| Mix ratio and strength | 1 tablet in 1 gallon of warm water yields about 200 parts per million. 2 tablets in 1 gallon yields about 400 parts per million |

| Contact time and finish | Keep surface visibly wet for at least 1 minute. Drain and air dry. Do not rinse or wipe after sanitizing |

| Water hardness tolerance | Labeled for use at 200 to 400 parts per million in water up to 500 milligrams per liter hardness as calcium carbonate |

| Water temperature guidance | Prepare solutions with warm water. For manual warewashing, the FDA Food Code specifies a minimum temperature of 75 degrees Fahrenheit for quaternary solutions, used at the concentration on the label |

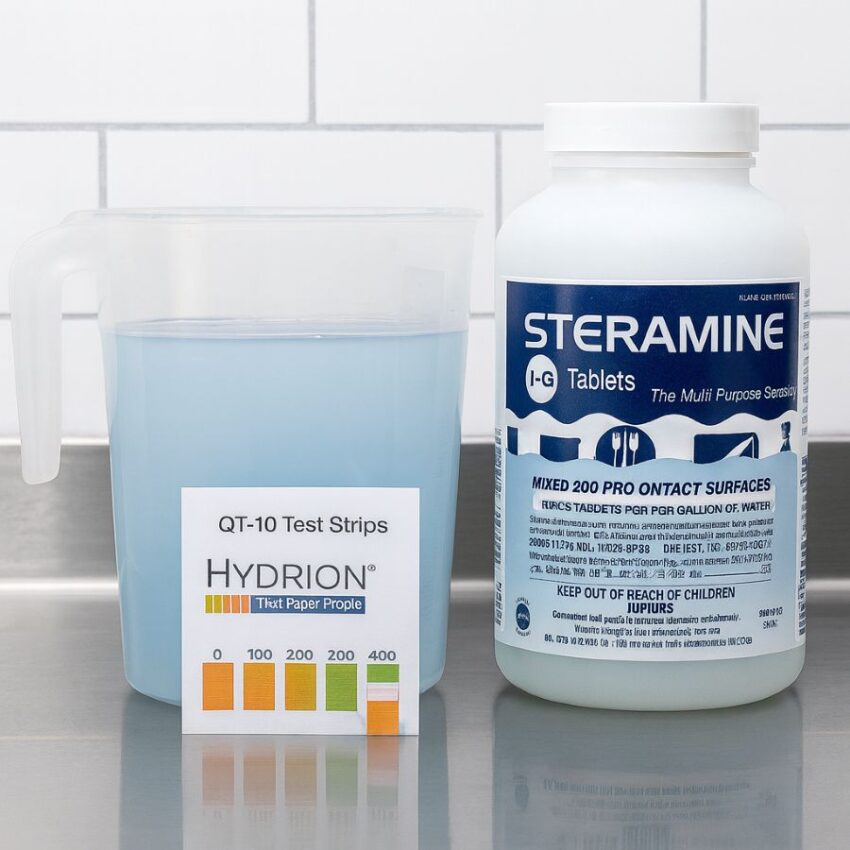

| Solution appearance | Dissolves to a clear, pale blue solution when mixed at use strength |

| Surfaces and uses | Hard, non-porous food-contact surfaces such as dishes, utensils, cutting boards, prep tables, sinks, refrigerators, and processing equipment. Labeled for 3-compartment sinks and spray or wipe applications on cleaned surfaces |

| Coverage per bottle | Up to 150 gallons of 200 parts per million solution from 150 tablets |

| Test strips included | Hydrion QT-10 range is 0 to 400 parts per million. Dip 10 seconds and read immediately. Test solution should be between 65 and 75 degrees Fahrenheit |

| Safety statements | Signal word: Warning. Tablet dust causes substantial but temporary eye injury. Avoid contact with eyes, skin, and clothing. Wash hands after handling. Tablets may be harmful if swallowed. First aid and physician directions appear on label |

| Storage and disposal | Store in original container out of reach of unauthorized users. Non-refillable container. Triple rinse promptly after emptying and recycle where available or discard in trash |

| Regulatory note | When used as directed at labeled concentrations, Steramine solutions may be used on food-contact articles and surfaces under 40 CFR 180.940 |

How to Use Steramine Sanitizer Tablets

Before you start: set up for success

Start with a clean sink, clean containers, and clean hands. Steramine is a sanitizer, not a cleaner, so wash and rinse first, then sanitize. Follow the EPA-stamped Steramine 1-G label for mixing and contact time, since the label is the legal instruction for use on food-contact articles.

Avoid getting tablet dust in your eyes, on skin, or on clothing. Store tablets in the original container, away from heat and moisture. Do not mix Steramine with bleach, soap, or other cleaners, and never mix quats with anionic detergents. Wash hands after handling.

Mix the right strength, the right way

- Fill a clean container with 1 gallon of warm water.

- Add 1 Steramine tablet for about 200 parts per million. For a 400 parts per million solution, use 2 tablets per gallon.

- Wait several minutes for tablets to dissolve completely, then stir. Steramine solution is typically pale blue at use strength.

- Keep surfaces visibly wet for at least 1 minute, then allow to drain and air-dry. No rinse is required when you follow the label.

Why warm water and not hot? Quats are used at relatively cool temperatures in manual warewashing. The FDA Food Code references a minimum of 75 degrees Fahrenheit for quaternary solutions, and the label sets the rest of the rules. If your local health department specifies a temperature window, follow that plus the Steramine label.

Verify with the included QT-10 strips

After mixing, test the solution. Dip a Hydrion QT-10 strip for 10 seconds in the sanitizer, then immediately compare the color to the chart. The manufacturer recommends testing solutions between 65 and 75 degrees Fahrenheit for accurate readings. Aim for about 200 parts per million for standard food-contact sanitizing, or the concentration you mixed by label.

Take a strip reading at setup, then again after the first hour of use, especially if you are soaking cloths or mops. Readings can drift downward during service.

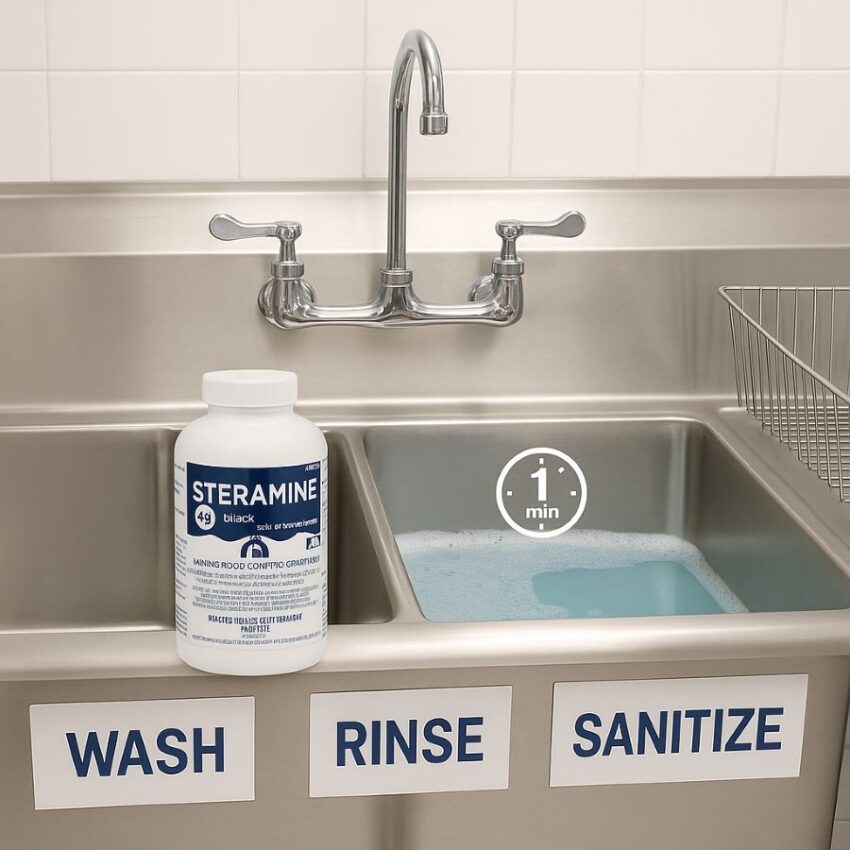

Three-compartment sink, the operator’s walkthrough

- Wash in hot, soapy water, then rinse in clean water.

- Sanitize by submerging clean items in Steramine solution at the label concentration. Keep them fully covered and wet for at least 1 minute.

- Air-dry on racks. Do not towel dry, since towels can re-contaminate clean ware.

Most jurisdictions train to use quats around 75 degrees Fahrenheit, in the 150 to 400 parts per million range. Always default to the Steramine label for concentration and contact time, and confirm your local code details.

Spray bottles and on-the-line wiping

For on-the-line touchpoints, mix Steramine into a clearly labeled spray bottle or wiping-cloth bucket. Pre-clean first, then spray or wipe to leave surfaces wet for at least 1 minute. Let them air-dry. Test each bottle or bucket with QT-10 paper before the shift and after heavy use.

Wiping cloth buckets and the “quat-binding” problem

Cotton and some viscose cloths can bind quats, which lowers the active concentration in your bucket even though the water still looks fine. In controlled tests, soaking cotton wipes in a quat solution cut the measured concentration roughly in half within minutes. Two ways to fight this: use low-lint microfiber that binds less, and keep a higher solution-to-cloth volume, for example larger buckets rather than small tubs. Most important, test often and change solution when readings drift.

Hard water, real kitchens

Steramine’s label supports use at 200 to 400 parts per million in water hardness up to 500 milligrams per liter as calcium carbonate, which covers many municipal supplies. If your water is harder than that or you see film or streaks, test more frequently and change out sooner.

How often to change the solution

Replace sanitizer when:

- the QT-10 strip drops below your target range,

- the water is visibly dirty, greasy, or cloudy,

- or at routine intervals during a busy day.

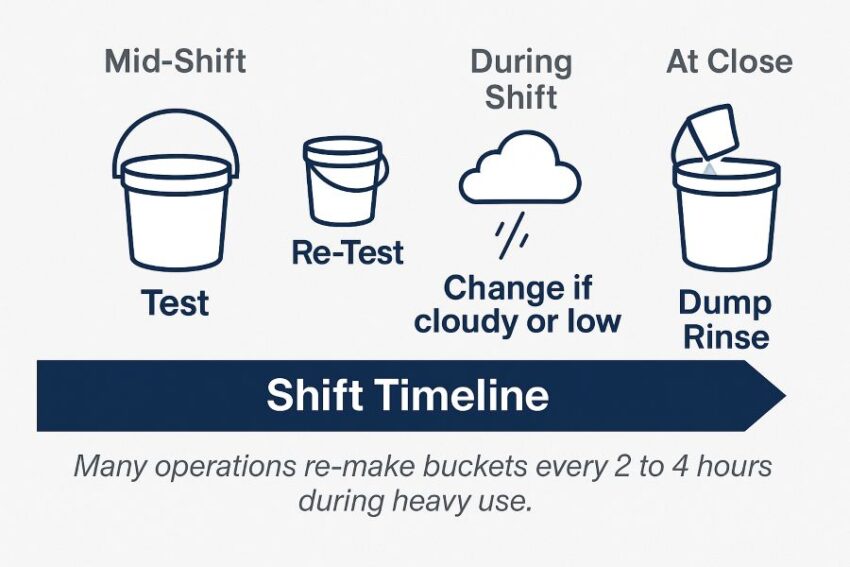

State health departments commonly coach operators to check and change buckets about every 2 to 4 hours, or more often if needed. That guidance pairs with the Food Code requirement to maintain proper concentration and to have a test kit in use.

Common Issues

- Reading is low after you load cloths: switch to microfiber and re-test, then add a fresh tablet to a new bucket. Quat binding is a known effect with cotton.

- Cloudy or food-soiled bucket: dump, rinse, mix fresh, and re-test. Soil consumes sanitizer. Follow your local two to four hour checks as a backstop.

- Unsure about temperature: aim for roughly 75 degrees Fahrenheit for manual quats unless your jurisdiction lists a narrow window. The Steramine label then governs contact time and concentration.

What not to do

Do not mix Steramine with bleach, oxidizers, soap, or anionic detergents. Mixing can neutralize the sanitizer or create hazards. Keep tablets in the original container and avoid cross-contamination of chemicals.

Daily routine that passes inspections

At opening, mix sanitizer exactly by the Steramine label, verify with QT-10 strips, and log the result. Keep wiping cloths fully submersed when not in use and re-test every few hours. Mid-shift, replace any solution that is dirty or that falls out of range. At close, dump, rinse, dry your buckets and bottles, and store tablets properly. This rhythm follows the Food Code’s focus on maintaining correct concentration and having a test kit on hand, while reflecting how real kitchens run during a rush.

FAQs about Steramine Sanitizer Tablets

1) Do I need to rinse Steramine off dishes or prep surfaces?

No. After you wash and rinse, sanitize and keep the surface visibly wet for at least one minute, then let it drain and air-dry. The Steramine 1-G label explicitly says: “Do not rinse or wipe” for spray or wipe applications, and for sink immersion it says to air-dry.

2) What is the right concentration, and how many tablets per gallon?

Use 1 tablet per gallon of warm water for about 200 parts per million, or 2 tablets per gallon for about 400 parts per million. The label allows 200 to 400 parts per million with a one-minute contact time.

3) What temperature should my quat sanitizer be during manual warewashing?

The FDA Food Code requires a minimum of 75 degrees Fahrenheit for quaternary ammonium solutions used in manual or mechanical warewashing. It also requires using them at the concentration on the product label.

4) Do I need test strips on site and how do I use the QT-10 papers?

Yes. The Food Code requires that sanitizer concentration be “accurately determined by using a test kit or other device.” Hydrion QT-10 directions say to dip for 10 seconds, then compare the color immediately. For the best accuracy, test between 65 and 75 degrees Fahrenheit.

5) How often should I change the mixed sanitizer?

At least daily, and sooner if the solution becomes diluted, dirty or out of range. The Steramine label says to prepare a fresh sanitizing solution at least daily, or more often if the solution becomes diluted or soiled. Many operators also change wiping-cloth buckets every 2 to 4 hours during rushes.

6) Why does my bucket test low after I add cotton towels?

This is the “quat binding” effect. Cotton and other cellulosic fibers can attract the positively charged quat, which lowers the active concentration in the bucket. Controlled studies found QAC levels reduced by as much as 85 percent after cotton towel exposure, which caused test failures. Use low-lint microfiber, keep a larger solution-to-cloth ratio, and test more often.

7) Can I spray Steramine on cutting boards and line stations instead of using a sink?

Yes. The label includes a spray direction for food-contact surfaces. Wash and rinse first, then apply a 200 to 400 parts per million solution and keep the surface wet for at least one minute, then allow to drain and air-dry. Do not rinse or wipe.

8) Is Steramine a disinfectant for viruses like norovirus or COVID-19?

Steramine 1-G is labeled as a food-contact sanitizer at 200 to 400 parts per million with a one-minute contact time, and the master label lists bacteria such as E. coli O157:H7 and Listeria. If you need a disinfectant with a norovirus claim, choose an EPA product on List G and verify the EPA Reg. No. If you need a product listed for SARS-CoV-2, use List N. Steramine 1-G is not presented on those lists as a food-contact disinfectant.

9) Is Steramine allowed on food, or only on food-contact surfaces?

Only on hard, non-porous food-contact articles and surfaces that will adequately drain before contact with food, consistent with the tolerance exemption in 40 CFR 180.940 referenced on the label. Do not apply Steramine directly to food.

10) What about glassware in bars. Will it spot or leave a taste?

Use at the labeled strength, keep contact for one minute, and air-dry. Spots usually reflect water hardness or soils, not the sanitizer itself. The label allows use in waters up to 500 milligrams per liter hardness and requires fresh solution if it becomes soiled. Testing and timely change-outs keep glassware clear.

11) How long do the tablets last in storage, and do they expire?

Vendors and distributor FAQs commonly state that Steramine tablets have a long shelf life, often described as about 10 years when stored properly, and that the printed date is the manufacture date. This is vendor guidance rather than an EPA label requirement, so store in the original container and follow all label precautions.

12) Can I run Steramine through a soft-serve machine for sanitizing?

Yes. The label includes stepwise directions for cleaning and sanitizing soft-serve or frozen dessert machines. Prepare the solution at 200 to 400 parts per million, circulate as directed, then drain and air-dry before refilling.

13) Can I mix Steramine with bleach or detergents to “boost” it?

No. Never mix cleaning chemicals. In general, quats can be incompatible with certain detergents and with chlorine products. Follow the label, wash and rinse first, then sanitize. For safety, authoritative sources remind operators not to mix sanitizers and to store chemicals in original containers.

14) What personal safety steps should staff take when handling tablets?

Avoid getting tablet dust in eyes, on skin or on clothing, and wash thoroughly after handling. The label carries a “Warning” signal word for tablet dust and provides first-aid statements. Store in the original container and keep out of reach of unauthorized users.

15) Operator tip from the field, about verification during a rush

Cooks and dish teams often re-test buckets mid-shift. Forum threads from working kitchens echo two practices that match the label and the Food Code: keep wiping cloths submerged when not in use, and change solutions any time they get cloudy or test out of range. Treat anecdotal tips as supplemental, then anchor decisions to your label and your local inspector’s guidance.

Conclusion

You want a sanitizer that is simple to mix, easy to verify, and clearly aligned with what inspectors expect. Steramine sanitizer tablets check those boxes with an EPA-registered food-contact claim at about 200 to 400 parts per million, a one-minute wet contact time, and no rinse when you follow the label. That combination gives you reliable results without slowing your team during a rush.

Paired with Hydrion QT-10 test strips, you can confirm your buckets and spray bottles at a glance. The QT-10 scale reads from zero to four hundred parts per million and is designed to be dipped for ten seconds, then read immediately at room temperature. In practice, that means less guesswork and fewer surprises at inspection time.

Reviews

There are no reviews yet.