Diversey J-512 TM/MC Sanitizer, 1-Gallon, 4/Case

$134.90

Bring your kitchen back to simple and safe. Diversey J-512 TM/MC Sanitizer is a concentrated, no-rinse food-contact sanitizer for three-compartment sinks, spray bottles, and wipe buckets. Mix 1 ounce per 4 gallons to reach the label range of 200 to 400 ppm quat, keep surfaces wet for 1 minute, then let them air dry. It is EPA Reg. No. 70627-63 and NSF D2 listed for no-rinse use on pre-cleaned food surfaces. This listing is the 1-gallon bottles, 4 per case, so you can standardize the same setup across prep, line, and dish.

Description

If you run a busy kitchen, you need a sanitizer that is simple to use and dependable in the moments that matter. Diversey J-512 TM/MC Sanitizer in the 1-gallon, case-of-4 format gives you a no rinse food contact surface sanitizer that is EPA registered and designed to sanitize at a 1:512 dilution, delivering 200 to 400 parts per million of quaternary ammonium with a quick 1 minute contact time on pre-cleaned food contact surfaces. This concentrated, red-tinted quat sanitizer is trusted in restaurants and food processing because it is certified for food-contact use and is formulated for the three compartment sink and spray applications without slowing your line.

Key Customer Benefits

- Real no-rinse confidence on food contact surfaces. When you dilute Diversey J-512 TM/MC Sanitizer correctly, you can sanitize prep tables, cutting boards, and utensils, then simply drain and air dry, no potable water rinse needed. That keeps your line moving during rush periods while staying compliant.

- Simple, proven dilution that crews remember. The label calls for 0.25 to 0.5 fluid ounces per gallon of water, which gives a target of 200 to 400 parts per million of active quaternary ammonium. That is the classic three-compartment sink sanitizer range that health inspectors look for, so staff can check with standard QAC test strips in seconds.

- Fast contact time, less downtime. After you pre-clean, a one minute wet contact time sanitizes food contact surfaces. That short dwell supports quick turnarounds on slicers, beverage dispensers, ice machines, and prep areas during service.

- Serious credentials that make audits easier. J-512 carries EPA Registration No. 70627-63 and is listed by NSF as a D2 no-rinse food contact surface sanitizer. Many distributors also note Kosher and Halal certifications, which can simplify multi-site standards and brand audits.

- Concentrate that saves space and money. Each one gallon bottle makes about 256 to 512 gallons of ready-to-use sanitizer based on the label’s 0.5 to 0.25 oz per gallon range. A 4-pack yields roughly 1,024 to 2,048 gallons, which reduces freight and back-room storage compared with ready-to-use products. Calculation shown here is based on EPA label directions.

- Clear, foodservice-friendly handling. The product is a red liquid with near-neutral concentrate pH, and it is designed for spray application or sink immersion, including the three-compartment sink. Those practical details help crews see coverage and integrate J-512 into existing cleaning SOPs without retooling.

Product Description

What this product is

Diversey J-512 TM/MC Sanitizer is a concentrated, quaternary ammonium food-contact surface sanitizer designed for busy foodservice and processing environments. At the labeled use rate, 0.25 to 0.5 fluid ounce per gallon of water, it delivers 200 to 400 parts per million of active quat and sanitizes in one minute on pre-cleaned, hard, non-porous surfaces. It is a true no-rinse sanitizer when used as directed, so after the contact time you simply drain and allow to air dry, which keeps your line moving and compliant.

Behind that simplicity is a robust registration and use scope. J-512 carries U.S. EPA Reg. No. 70627-63 and lists the active ingredients as benzalkonium chloride and ethylbenzyl ammonium chloride, a well-known quat pairing for food-contact sanitizing. The EPA master label also details where it can be used, including prep tables, deli slicers, beverage dispensers, ice machines, and CIP systems.

J-512 is also independently registered by NSF as a D2 no-rinse food-contact surface sanitizer. That D2 listing gives operators and auditors confidence that, on previously cleaned surfaces, a potable water rinse is not required after the labeled contact time, provided the surface is allowed to drain.

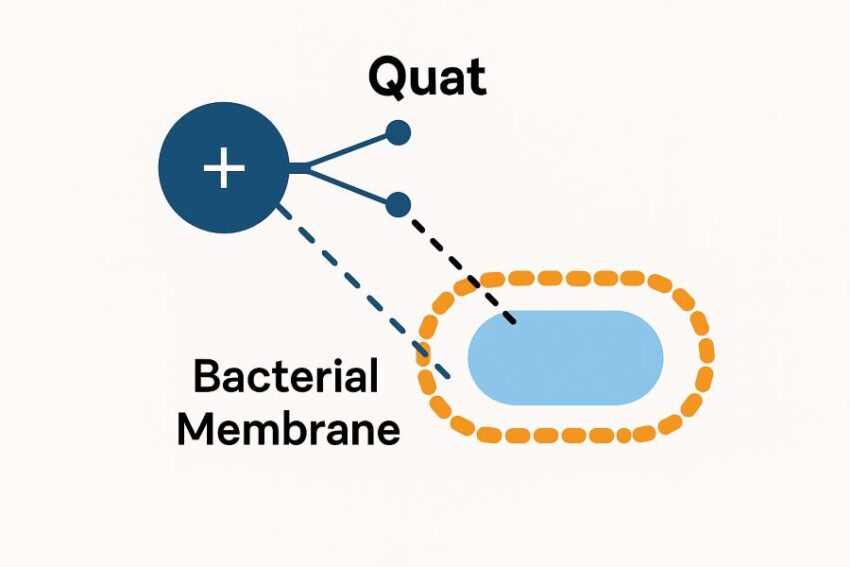

How it works

Quats carry a positive charge that is attracted to the negatively charged cell membranes of bacteria. When they bind, they disrupt the membrane and essential cellular processes, which leads to cell leakage and death. This well-studied mode of action is why quats have been used for decades on food-contact surfaces at low concentrations that are friendly to metals and finishes compared with harsher oxidizers.

The label-specified 200 to 400 parts per million range is not arbitrary. It is the range food codes and health departments commonly reference for quat sanitizers in three-compartment sinks and for wipe buckets. It balances efficacy with minimal residue, and it is easy to verify with standard QAC test strips during service and throughout the day.

What makes J-512 effective and different

First, the product is purpose-built for food-contact applications. The EPA label spells out a one minute wet contact time for food-contact sanitizing, along with explicit no-rinse directions for beverage systems, ice machines, conveyors, and general food-processing equipment. Clear, specific directions reduce ambiguity during audits, so crews know exactly what “done right” looks like.

Second, J-512 performs in real-world water. Distributor technical literature for this SKU documents efficacy in the presence of 500 parts per million hard water at the 1:512 dilution, which is what many operators actually have at the tap. That matters because water hardness can blunt sanitizer performance if you choose the wrong chemistry.

Third, the concentrate itself is engineered for foodservice practicality. The SDS notes a clear red liquid, product-specific odor with no added fragrance, near-neutral pH in use, and a specific gravity near water, so it mixes easily. The same SDS also highlights critical safety controls for the concentrate, for example do not mix with bleach and wear proper eye and skin protection when handling the undiluted product. Those details help you write precise SOPs for storage, dilution, and training.

Product Specifications

| Attribute | Detail |

|---|---|

| Product name | Diversey J-512 TM, MC Sanitizer, 1 gallon bottles, case of 4, concentrate. |

| Manufacturer | Diversey, Inc. Fort Mill, South Carolina. |

| EPA registration | EPA Reg. No. 70627-63. |

| Active ingredients | Alkyl dimethyl benzyl ammonium chloride, 5.0 percent and alkyl dimethyl ethylbenzyl ammonium chloride, 5.0 percent. |

| Dilution for food contact sanitizing | 1 to 512 ratio, which is 1.0 fluid ounce per 4 gallons of water or 0.25 fluid ounce per 1 gallon of water. |

| Target concentration at use | 200 to 400 parts per million active quaternary ammonium. |

| Required contact time | 1 minute on pre cleaned, hard, non porous food contact surfaces. |

| Rinse requirement | No potable water rinse is required when used as a sanitizer on food contact surfaces. Allow to drain and air dry. |

| Efficacy conditions noted on label | Food contact sanitizing is validated in the presence of 500 ppm hard water with 99.999 percent reduction in 1 minute. |

| Form, color, scent | Red liquid, typical quaternary odor. The SDS notes no added fragrance. |

| pH | About 7.9 for the concentrate. The diluted use solution is about pH 7. |

| Shelf life | 3 years, when stored as directed. |

| Packaging options and codes | 4 x 1 gallon case, code 5756018. Also available in J Fill 2.5 liter, code 5756034 and other package formats. |

| Compatible dispensing systems | J Fill, SmartDose, RTD, Solutions Center and others listed on the EPA master label. |

| Typical use sites and equipment | Three compartment sink, wipe buckets, deli slicers, beverage and ice equipment, conveyors and general food processing equipment. |

| Certifications | NSF D2 no rinse food contact surface sanitizer listing and Kosher and Halal noted by the manufacturer. |

| Case yield at label dilution | One gallon of concentrate makes about 512 gallons of ready to use sanitizer at 200 ppm or about 256 gallons at 400 ppm. A 4 pack case yields about 1,024 to 2,048 gallons. Calculation shown here is based on the label directions of 1 ounce per 4 gallons or 0.25 to 0.5 ounce per gallon. |

| Safety and handling, concentrate | Signal word Danger. Causes severe skin burns and serious eye damage. Wear chemical splash goggles, protective gloves and suitable clothing when handling the undiluted product. Do not mix with bleach. |

| Transportation, concentrate | U.S. DOT description, UN3267, corrosive liquid, basic, organic, not otherwise specified, quaternary ammonium compounds, Class 8, Packing Group III. |

How to Use

Before you start

Set yourself up for success the same way you would set a cook’s station. Bring chemical-splash goggles, gloves, and your quat test strips, then make sure there is no bleach anywhere near your mixing area. Diversey’s current Safety Data Sheet for the Final Step 512 formulation spells this out clearly: mix only with water, do not mix with bleach or oxidizers, and wear appropriate eye and skin protection when handling the concentrate.

What you need on the counter: the J-512 concentrate, cool potable water, a clean graduated cup or a closed-loop dispenser, a labeled bucket or sink, and QAC test strips that read in the 0 to 500 ppm range. The strips let you confirm that your solution sits in the 200 to 400 ppm sweet spot for a no rinse food contact surface sanitizer. State extension guidance and foodservice articles consistently reference 200 ppm as the standard target for quats unless your label says otherwise, which J-512 does not.

Choose your mixing method

Closed-loop dispensing for speed and safety. If you have Diversey SmartDose, Command Center, or similar equipment, use it. The EPA master label for this product family specifically lists these systems and notes they deliver the correct dose for the labeled dilutions. This reduces direct handling and keeps your crew from guessing at ounces.

Manual mixing when you must. For food contact sanitizing, J-512 is used at 1 to 512. That equals 0.25 fluid ounce per 1 gallon of water, or 1 fluid ounce per 4 gallons. Stir gently, then verify with a quat strip. If the strip reads below 200 ppm, add a little concentrate. If it reads above 400 ppm, add water, stir, and test again. The label also tells you to make fresh solution at least daily or sooner if it becomes dirty or is diluted.

Measuring tiny volumes into a spray bottle leads to swings in ppm. Mix a larger batch in a bucket at the correct ratio and refill bottles from that bucket, then test the bucket and a sample from the bottle. That practice comes up often in operator threads and keeps inspections drama-free.

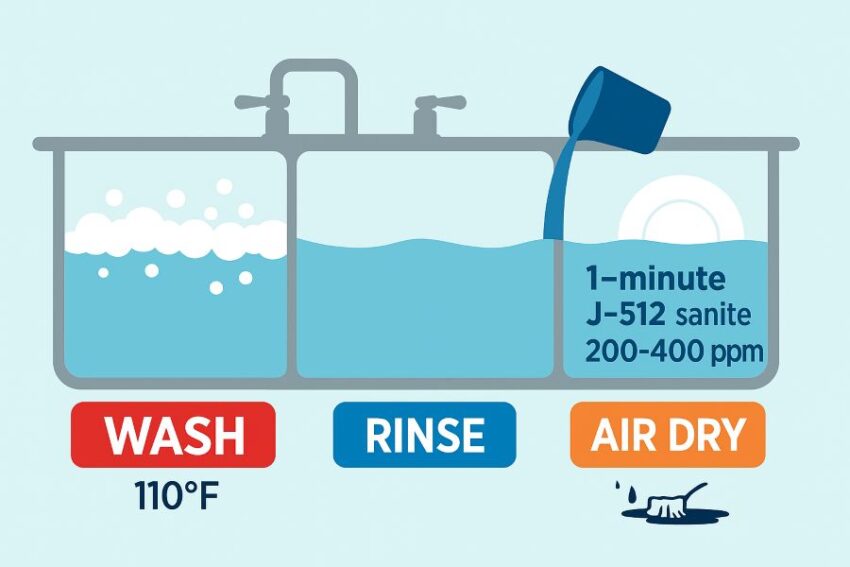

Three-compartment sink set up, step by step

- Wash. Fill the first sink with hot water and detergent. Most health department guides point to at least 110 degrees Fahrenheit for the wash and rinse basins. Scrape first, then wash thoroughly.

- Rinse. Use clean water in the second sink to remove detergent. Residual soap can neutralize quats, so rinsing well matters. The SDS also cautions against anionic surfactants, which is one reason you rinse detergent completely before sanitizing.

- Sanitize. In the third sink, add J-512 at 1 to 512 and confirm 200 to 400 ppm with a test strip. Immerse cookware and utensils so all surfaces stay wet for 1 minute. Remove and air dry. No potable water rinse is required for food contact sanitizing when you follow the label.

If your strip shows 150 ppm after a lunch rush, top up with a small amount of concentrate, stir, and re-test. If you find yourself creeping over 400 ppm, do not assume stronger is better. County health guidance is explicit that too much sanitizer can damage equipment or leave off-odors and still not improve results.

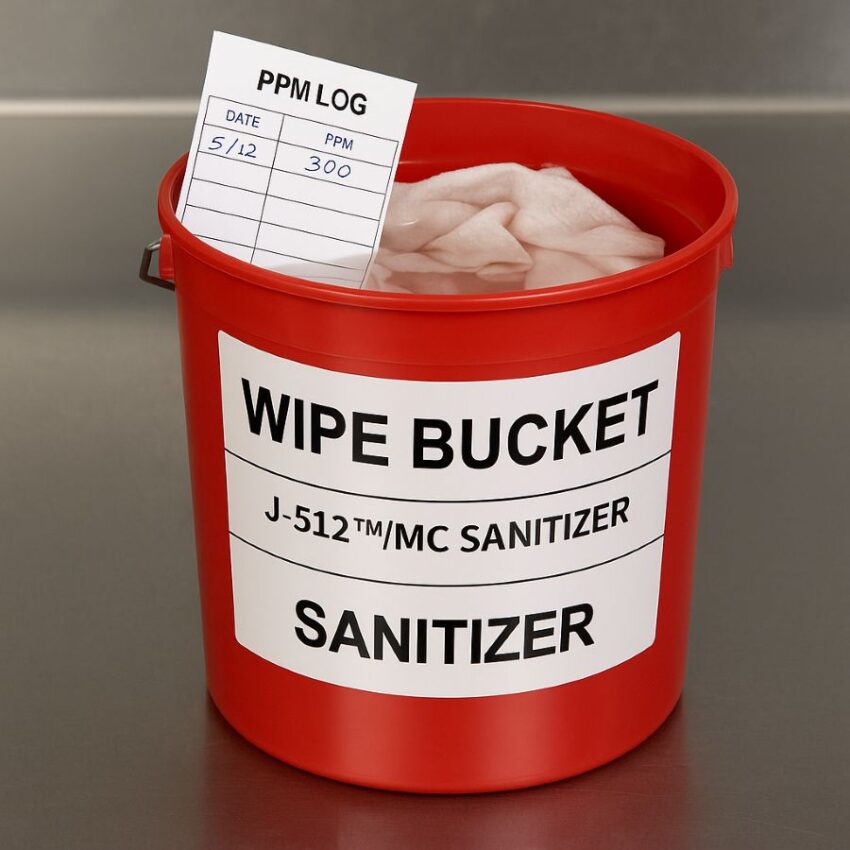

Wipe buckets and spray bottles for the line

Prepare a bucket of 1 to 512 solution and park labeled towels in it for wipe-down of cutting boards, make-tables, and counters. Keep the towels submerged when not in use, and swap the solution at least once per day or sooner if it turns cloudy or heavily soiled. The J-512 label directs you to prepare fresh sanitizer daily or when visibly dirty, and to maintain 200 to 400 ppm.

For spray bottles, fill from the validated bucket instead of measuring drops at the bottle. Hold the trigger sprayer 6 to 8 inches from the surface, wet the area thoroughly, and allow a 1 minute contact time. Cover or remove food before spraying. Drain and air dry.

Beverage dispensers, ice machines, slicers, and stationary equipment

The label allows sanitizing of deli slicers, beverage dispensing equipment, and ice machines once they have been cleaned and rinsed. Apply 0.25 to 0.5 ounce per gallon solution by spray or swab until the surface is completely wet, hold for 1 minute, then drain and air dry. Always follow the equipment manufacturer’s instructions for any disassembly or CIP steps and remove or cover food prior to spraying.

Circulation and CIP, including RO units and softeners

If you sanitize lines or tanks by circulating a solution, the label says to prepare 200 to 400 ppm and run pumps long enough to wet all internal surfaces. It specifies at least 2 minutes of circulation to wet the system, while the sanitizer still needs 1 minute of contact on surfaces. For RO systems and water softeners, the label provides detailed steps including when to backwash and when to flush with potable water afterward. Keep those procedures with your SOP binder and follow them as written.

Testing, logging, and staying audit-ready

Quat test strips are your daily proof that the solution matches the label. Use QAC strips rated 0 to 500 ppm. Dip for the time the strip maker specifies and read against the color scale. Record ppm and time on a simple log taped inside the sink cabinet or beside the make-table. Procurement teams often stock dual kits for chlorine and quats; for J-512 you need the quat side.

If your water is hard, J-512’s food contact sanitizing claim is validated in 500 ppm hard water at 1 to 512 with a 1 minute contact time, which is exactly the situation many kitchens face. Keep testing during busy periods since towels and soil can drag ppm down.

Common pitfalls I see and how to fix them

- Over-concentration to “be extra safe.” More concentrate does not equal better sanitizing and can leave taste or film on surfaces. Dial it back to the label range and re-test.

- Mixing near bleach. Never combine with bleach or oxidizers; even accidental cross-contact in a sink can create hazardous gas. Store separately and post a “mix with water only” reminder.

- Soap carryover. Quats and many detergents do not play nicely together. Rinse well before sanitizing to keep your ppm meaningful. The SDS notes anionic surfactants as materials to avoid.

- Tiny bottle math. A quart bottle at 1 to 512 needs roughly 0.06 ounce of concentrate, which is tough to dose consistently. Mix in bulk, then decant to bottles and validate with strips. Operator guides for three-comp sinks and sanitizer practice back up this approach.

Frequently Asked Questions

Do I have to rinse J-512 off food contact surfaces?

No rinse is required when you use Diversey J-512 at the labeled food contact sanitizing dilution, then let surfaces drain and air dry. The EPA master label specifically states that a potable water rinse is not required after sanitizing on food contact surfaces as long as the surface is adequately drained. NSF also lists the product as D2, which is the no-rinse food contact category.

What is the correct dilution to hit 200 ppm or 400 ppm?

For food contact sanitizing, mix 1 ounce per 4 gallons of water or 0.25 ounce per 1 gallon. That produces 200 to 400 parts per million of active quaternary ammonium, which is the label range for J-512.

What is the contact time for food contact surfaces?

Hold surfaces wet for 1 minute at the food contact dilution, then drain and air dry. Industry guidance often notes one minute as the typical contact time for food contact sanitizers, which aligns with the J-512 label.

Can I use it in a three-compartment sink, and what temperatures should I follow?

Yes. Wash in hot water, rinse, then sanitize in the third sink with J-512 mixed to 200 to 400 ppm and held for 1 minute. Many health departments teach a three-compartment workflow with wash water at 110 degrees Fahrenheit and quats used at 200 to 400 ppm. Follow the J-512 label for the one-minute contact time.

How do I test that my solution is really 200 to 400 ppm?

Use QAC test strips designed for quaternary ammonium. Dip as directed, then match the color immediately. Most test strip makers advise testing at room temperature, roughly 65 to 75 degrees Fahrenheit, for accurate readings. If your strip shows below 200 ppm, remix or add a touch of concentrate. If it reads above 400 ppm, dilute with water and retest.

My auditor asked how I know we are not over 400 ppm if our strips only read to 400. What should I do?

This is a common audit question. The practical fix is to stock higher-range quat strips, for example up to 1,000 or 1,500 ppm, and demonstrate that your in-use solution sits in range.

Does J-512 work in hard water?

Yes. The food contact sanitizing claim is validated in 500 ppm hard water at 1 to 512 dilution with a one-minute contact time and a 99.999 percent bacterial reduction.

Can I spray it on beverage dispensers, ice machines, and slicers?

Yes, once those items are cleaned first. The J-512 label specifically lists deli slicers, beverage equipment, and ice machines as approved applications at the food contact sanitizing dilution and contact time.

Do towels or cloth types affect quat strength in my wipe buckets?

They can. Studies show quats can bind to textiles, especially cotton and some microfiber designs, which can drag your ppm down. Consider quat-compatible microfiber or polyester wipes, avoid cotton, minimize soak time in buckets, and verify with strips during the shift.

Can I mix J-512 with bleach or other cleaners?

No. The current Safety Data Sheet warns to mix with water only. Do not mix with bleach or oxidizers since that can release chlorine gas. Store separately and train staff to avoid cross-mixing.

Does soap residue interfere with quat sanitizers?

Yes. Quat activity can be reduced by some detergents and soap residues, which is why the Food Code workflow is clean, rinse, then sanitize. Rinse well before sanitizing so the quat solution can do its job.

How often should I remake my sanitizer solution or wipe buckets?

Make fresh solution at least daily and any time it becomes visibly dirty, and recheck ppm during busy service. The label also directs users to prepare fresh sanitizer regularly.

What water temperature should I use to dilute J-512?

When you use a closed-loop dispenser listed on the label, the directions say to dispense with cold water. For manual testing with strips, manufacturers typically recommend measuring at room temperature for accuracy.

Can J-512 also disinfect non-food contact surfaces?

Yes, the label includes disinfectant directions at a stronger dilution with a longer contact time for non-food contact uses. Check the Disinfectant section of the EPA label for the exact ratio and contact times for the organisms listed.

Any quick tips to stay inspection-ready with a quat sanitizer?

Keep a simple log for ppm checks, label your buckets and bottles, hold to 200 to 400 ppm at one minute, and train staff to air dry rather than towel dry. Several health departments publish quick guides that mirror those steps.

Conclusion

When your kitchen is humming and the ticket rail will not quit, you need a sanitizer that is predictable, fast, and audit friendly. Diversey J-512 TM/MC Sanitizer gives you that mix of confidence and speed, with a label that spells out 1 to 512 dilution, one minute contact time, and true no-rinse use on food contact surfaces once they are pre-cleaned. It is even validated at 500 parts per million hard water, which reflects the real tap water many operators work with every day.

There is substance behind that convenience. J-512 is EPA registered and carries an NSF D2 no-rinse food contact listing, so your team and your inspectors are reading from the same playbook. If you standardize around those directions and verify with quat test strips, you will be in the range health departments expect to see on the line.

Reviews

There are no reviews yet.