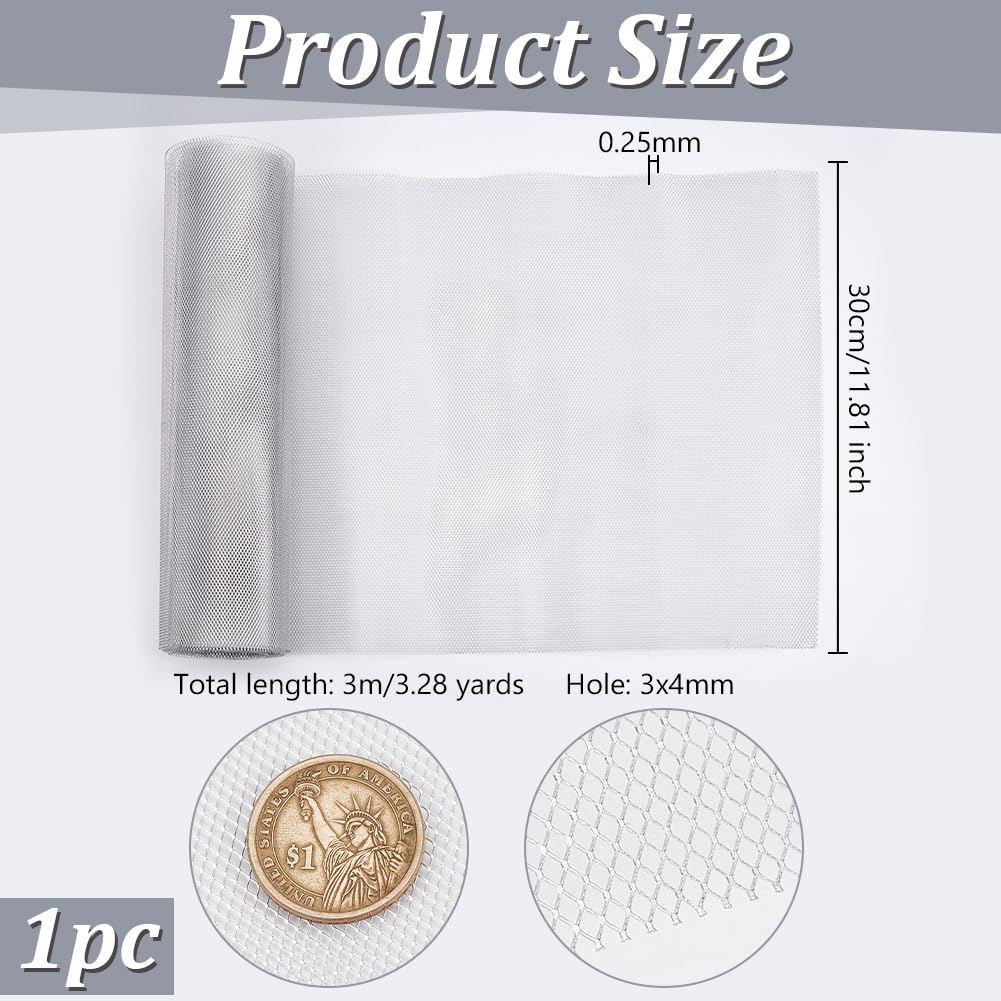

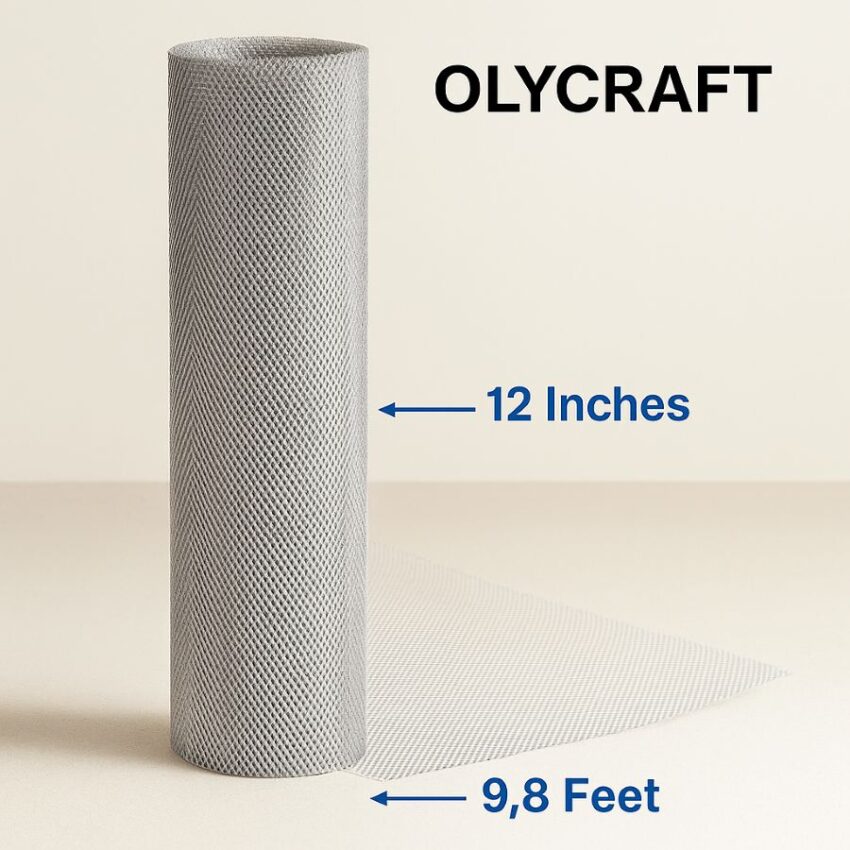

OLYCRAFT White Aluminum Sculpting Mesh, 12″ × 9.8′ – 0.25 mm Thick

$16.39

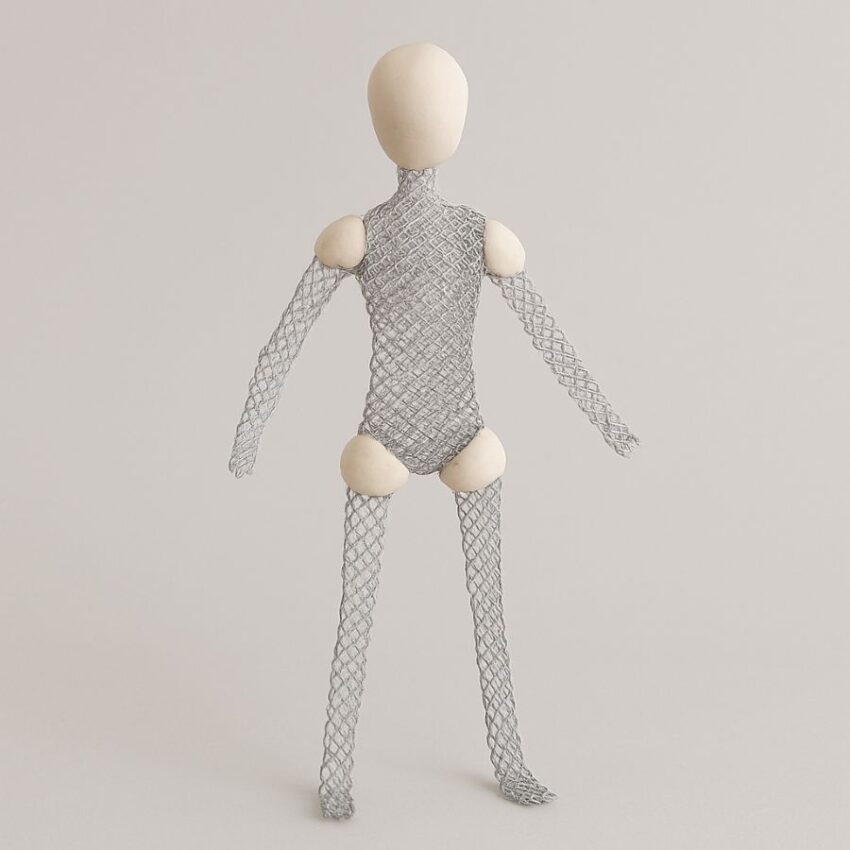

Shape, brace, and build smarter with OLYCRAFT White Sculpting Wire Mesh – a lightweight aluminum expanded mesh roll that is 12 inches wide by 9.8 feet long with about 0.25 millimeter wire and small diamond openings. It cuts cleanly with craft shears, creases to hold curves, and plays nicely with polymer clay, since metal armatures can be baked at typical cure settings. Aluminum’s naturally protective oxide layer resists everyday corrosion, so your armatures stay clean while you work or store pieces. Ideal for masks, maquettes, and jewelry cores when you want strength without bulk.

Description

When you need a clean, lightweight armature that shapes fast and holds form without fighting you, the OLYCRAFT White Sculpting Wire Mesh 12 inch by 9.8 ft, 0.25 mm thick hits the sweet spot. It is an aluminum mesh roll with roughly 3 by 4 millimeter openings in a 30 cm × 3 m format, so you get a generous, easy-to-cut canvas for clay armatures, maquettes, jewelry frames, and small diorama work.

As a clay person at heart, I also like that aluminum is a studio-friendly choice for polymer-clay builds because it tolerates bake temps and does not expand much, which helps prevent cracking around your armature.

Key Customer Benefits

- Lightweight control that still holds shape. Aluminum mesh weighs about one third as much as comparable steel mesh, so it is easier on your hands and wrists during long sculpting sessions, yet it keeps a reliable form once you press, crimp, or fold it. That balance of low weight and rigidity is why artists favor aluminum armatures for clay, paper-mache, and maquettes.

- Sized for real builds, not scraps. The roll is about 12 inches wide by 9.8 feet long with an approximate 0.25 millimeter wire thickness and small 3 by 4 millimeter openings. That footprint lets you skin full torsos, mask forms, or multiple jewelry blanks without splicing tiny offcuts.

- Polymer-clay friendly in the oven. Aluminum and most metals can be baked with polymer clay at normal cure temperatures. Makers commonly use metal armatures because they do not meaningfully expand at bake temps and therefore help reduce cracking around the core. Practical tutorials from polymer-clay educators back this up.

- Cuts cleanly with shop shears. Craft-grade aluminum sculpting mesh is designed to snip with household scissors or light snips. That means fewer jagged edges, faster patterning, and less fatigue compared with stiffer welded meshes.

- Resists everyday corrosion so your armature lasts. Aluminum forms a protective oxide layer that stands up well to normal studio humidity. If you seal your finished piece, this helps the inner armature stay stable over time.

- Easy adhesion and surface prep tips from the community. Many sculptors wrap a thin layer of aluminum foil or add a film of liquid clay over mesh to give fresh clay more “tooth” and to reduce the amount of bulk clay you need. This is a simple trick that improves bond and saves material.

Product Description

What this mesh is

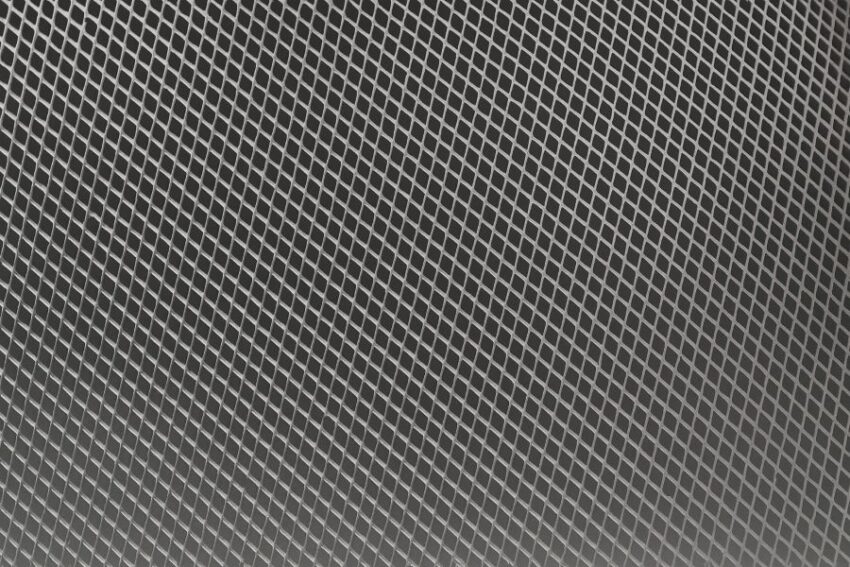

The OLYCRAFT White Sculpting Wire Mesh is a light, flexible aluminum armature mesh supplied as a 30 centimeter, roughly 12 inch, wide roll that is 3 meters, roughly 9.8 feet, long with a wire thickness around 0.25 millimeter and small diamond openings about 3 by 4 millimeters. In practice, that means you get a generous, easy-to-cut sheet that shapes by hand for clay armatures, masks, mixed-media jewelry, and small props. Multiple OLYCRAFT retail listings confirm those core specs and the small-hole pattern that makers look for when they need support without bulk.

How it works as an armature and support

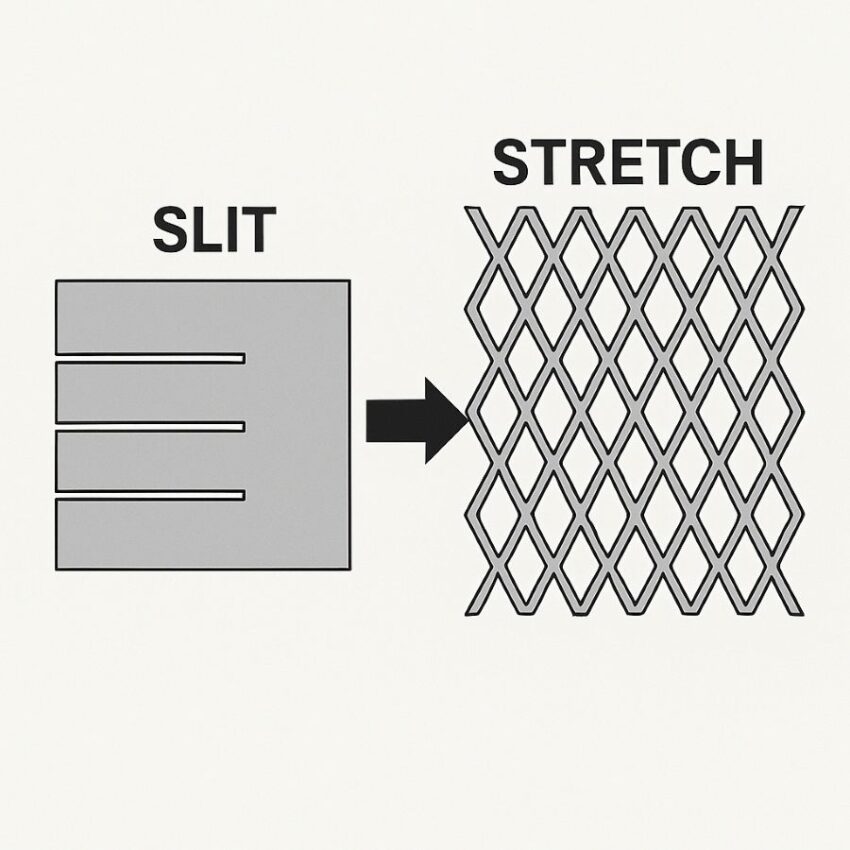

Aluminum is popular in studios because it is light, it work-hardens where you crease it, and it naturally develops a protective oxide skin that resists everyday tarnish. For sculptors, that means you can crimp, fold, and form the mesh to create a rigid under-shape, then add clay, paper-mache, or textile over it. Expanded aluminum meshes are made by slitting and stretching sheet metal, which creates the familiar diamond openings that allow air and heat to pass while adding stiffness along the bonds of the diamonds.

When you use polymer clay, the armature can go right into the oven with the piece. Polymer-clay educators and the Sculpey brand’s own guidance explain that metals, including aluminum, can be baked with polymer clay at typical cure temperatures. The key is correct temperature control and sufficient time for the clay’s thickness, plus simple shielding like an aluminum-foil tent if you notice browning.

Why this mesh is effective and different

Good balance of flexibility and hold. Craft-grade aluminum mesh is designed to be shaped by hand and cut with household scissors or light snips, which speeds patterning compared with stiffer welded steel. Maker listings and craft-supply guides call out that it is “easy to cut” while still holding contours after a crease or press.

Studio-friendly material. Aluminum’s surface forms a thin alumina layer that protects against everyday oxidation, so stored armatures do not shed rust on your clay or fabric. Materials research and industry explain this protective effect, and also note that formal anodizing can further enhance wear and corrosion resistance if you plan to leave mesh exposed in a finished piece.

Right-sized openings for grip. The about 3 by 4 millimeter diamond pattern gives fresh clay “tooth,” especially if you first burnish a skim of liquid clay or wrap a thin foil layer to increase mechanical keying. Community tutorials and maker threads frequently recommend this simple trick for stronger bonding and to reduce the bulk clay needed over an armature.

Product Specifications

| Spec | Details |

|---|---|

| Brand / Item | OLYCRAFT White Sculpting Wire Mesh |

| Material & Type | Aluminum, expanded “diamond” mesh (slit and stretched from solid sheet) |

| Color | White (as listed) |

| Roll Width | 30 cm, roughly 11.8 inches |

| Roll Length | 3 m, roughly 9.8 feet |

| Approx. Coverage Area | 0.90 square meter, roughly 9.69 square feet (handy for planning masks, busts, or multiple jewelry blanks) – calculation from the supplied width and length |

| Wire Thickness | About 0.25 millimeter |

| Mesh Opening (approx.) | About 3 × 4 millimeter diamond openings (“small holes” in listing language) |

| Formability | Hand-bendable; holds creases; “easy to cut” for craft use (household scissors or light snips are commonly sufficient) |

| Typical Uses | Clay armatures, masks, small props, mixed-media jewelry, paper-mache under-structures, model-making, and light craft screening |

| Polymer-Clay Compatibility | Metals such as aluminum can be baked with polymer clay at typical cure settings. Sculpey’s guidance: 275 degrees Fahrenheit / 130 degrees Celsius for 15 to 30 minutes per quarter inch of clay thickness, tenting with foil if needed. |

| Manufacturing Method | Expanded metal, produced by slitting and stretching a solid sheet to form uniform diamond openings (strong and will not unravel like woven mesh) |

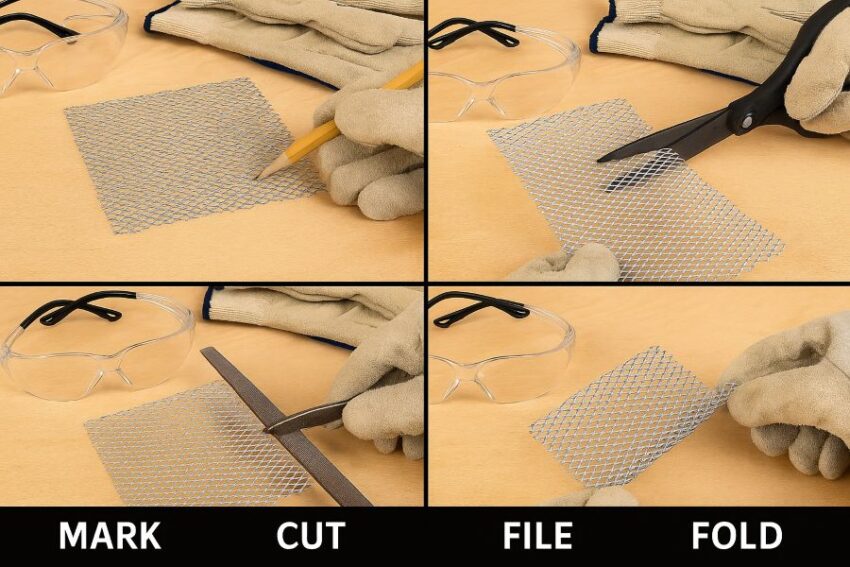

| Cutting & Edge Care | Cut with scissors or light snips; edges can be sharp, so wear gloves and eye protection; deburr with a small file if the edge will be handled. (“be a little careful when cutting” per listing.) |

| Safety Notes | For oven-baked polymer clay: verify temperature with an oven thermometer; shield with a loose foil tent if browning. Avoid plastics that can off-gas at bake temps. |

| What’s in the Box | One roll, 30 cm × 3 m aluminum sculpting mesh in white finish |

| Certifications | None stated in manufacturer or retail listings for this craft mesh (no formal corrosion or food-contact ratings claimed). |

How to Use / Installation Guide

You do not need a shop full of tools to get great results with OLYCRAFT White Sculpting Wire Mesh 12 inch by 9.8 ft, 0.25 mm. Below is a studio tested workflow that covers templating, forming, securing, and curing with polymer clay or mixed media. I have also added a short note from a pest-control lens so you do not accidentally use a craft mesh where a structural exclusion screen is required.

What you will need

A marker and paper for patterns, light snips or sturdy craft scissors, masking tape, a small flat file, thin aluminum foil, liquid polymer clay or a bakeable clay adhesive, an oven thermometer, and a smooth tile or baking tray for curing. The OLYCRAFT roll is about 30 cm wide by 3 m long with 0.25 mm wire and small diamond holes around 3 by 4 millimeters, so it cuts cleanly and shapes by hand. The product listings confirm those core specs, and they also remind you to take care when cutting because freshly cut edges can be sharp.

Step 1. Plan the shape and make a quick paper template

Sketch the form, then make a paper pattern that fits your face, object, or jewelry blank. Keep in mind how expanded aluminum mesh behaves. It starts as a solid sheet that is slit and stretched to create the diamond openings, which means it has natural stiffness along the bonds and can be curved smoothly without unraveling. Understanding this lets you pick the direction that gives you the most support.

Step 2. Cut safely and tame the edges

Transfer the pattern to the mesh and cut slightly outside your line. Aluminum craft mesh is designed to be easy to cut and form, yet any fresh edge can nick skin. Wear light gloves, snip slowly, and dress the edge with a small file if the piece will be handled. Home-improvement and craft listings for expanded aluminum consistently call out that it cuts and forms easily, and that aluminum will not rust in normal studio humidity.

Step 3. Shape and seam the shell

Curve the mesh over a bowl, mannequin head, dowel, or any smooth form. Crease gently to lock in curves. For larger builds, overlap seams by at least one full diamond and crimp the overlap with pliers. Because expanded mesh is one piece rather than woven wires, overlapped seams hold well after a light crimp and a wrap of masking tape while you work.

Step 4. Give clay something to grip

For polymer clay skins, two community proven tricks improve bonding and reduce bulk clay:

1) Foil underlay. Burnish a thin layer of aluminum foil to the mesh so the surface is continuous. Polymer-clay educators recommend foil cores because they even out clay thickness and help pieces cure more consistently. Avoid trapping air. Start pressing clay at the center and work outward to push out any air pockets.

2) Liquid clay or bakeable adhesive at contact points. A film of liquid polymer clay at the interface helps raw clay grab raw clay across seams. Testing from respected polymer-clay educators shows bakeable adhesives and liquid clays are effective for clay-to-clay bonds. Use gel cyanoacrylate or two-part epoxy if you must attach a metal finding after curing.

Some niche sources point out that certain bakeable glues are best for clay-to-clay rather than clay-to-metal. If you are relying on the metal mesh itself for a finished jewelry bond, plan a mechanical key through the diamonds or embed a baked-in loop instead of trusting a surface glue alone.

Step 5. Cure correctly with polymer clay

Place the piece on a smooth tile or tray. Preheat to 275 degrees Fahrenheit, that is 130 degrees Celsius, and bake 15 to 30 minutes for each quarter inch of clay thickness. Use an oven thermometer to verify the true temperature. If you notice browning, tent loosely with foil. These instructions come directly from Sculpey’s official baking guides.

Step 6. Finish cleanly

After cooling, refine edges with a file or sandpaper where the mesh is exposed. If the mesh edge will touch skin in a wearable, fold the edge under before baking or encapsulate it in clay. If you plan to leave aluminum visible, remember why aluminum behaves well in studios. It forms a thin oxide layer in ordinary air that protects against further corrosion. Clean fingerprints with mild soap and water and dry thoroughly.

Quick setup for jewelry, masks, and mini props

- Bracelet or cuff core: wrap mesh around a dowel, fold the long edges back to dull them, build a thin clay skin, then cure. The mesh keeps the curve and reduces weight. The slit and stretch geometry lets the cuff spring slightly without cracking the clay.

- Mask or beak: use three panels overlapped by one diamond each to build compound curves, foil over the whole, then add clay. Watch for trapped air as Sculpey’s armature tutorial warns.

- Pendant blanks and wings: cut light shapes, gently dome over a spoon, seal the edge inside clay, and cure on a tile. Sculpey highlights aluminum mesh and wire as mixed-media armatures that work well with clay because they do not shrink during curing.

Frequently Asked Questions

Can I bake polymer clay over an aluminum mesh armature?

Yes. Sculpey’s official guidance confirms that metal armatures can go in the oven at typical cure settings, which for many Sculpey clays is 275 degrees Fahrenheit, that is 130 degrees Celsius, for 15 to 30 minutes per quarter inch of clay. Use an oven thermometer and tent with foil if browning appears. Makers in polymer clay communities also routinely bake clay over aluminum foil and metal armatures with good results.

Will the clay stick to aluminum mesh or foil, or do I need a glue?

Raw polymer clay bonds to itself mechanically. To improve grip over mesh, many artists apply a thin layer of liquid polymer clay before laying on sheets, or they burnish a thin foil underlay to make a continuous surface that avoids trapped air. Forum and educator tips emphasize pressing out air pockets before curing to minimize cracking. Save superglue or epoxy for post bake metal findings.

What is the safest way to cut and shape this aluminum mesh?

For craft thickness aluminum mesh, sturdy craft shears or light tin snips are commonly recommended by hobbyists who cut mesh daily. If you are cutting heavier expanded metal, makers often switch to powered options like a jigsaw with a metal blade or an angle grinder. Whichever tool you use, wear eye protection, go slow, and dress fresh edges with a file.

Does aluminum rust or stain my project over time?

Aluminum does not rust like iron. Instead it forms a thin aluminum oxide film that protects against further corrosion in normal environments. That self formed barrier is why aluminum mesh armatures store well and do not leave red rust on your materials. If you plan outdoor exposure or salty conditions, seal the piece as aluminum can still corrode in harsh settings.

I heard metal gets hotter than clay and can burn it. True or false?

Mostly false in normal use. Independent polymer clay educators explain that you can bake clay with metal inside. The metal itself is not a problem at standard cure temperatures. Burning happens when temperature control is poor or when thin clay near a hot element overheats. Shielding with a loose foil tent and accurate temperature control prevent scorching.

Do I need to worry about moisture in the armature when I bake?

Yes, but mostly with non metal bases. Sculpey warns that materials which hold moisture, like wood or certain stones, can expand during baking and cause cracks. Metals and glass are preferred because they do not hold moisture and do not meaningfully expand at bake temperatures.

What mesh opening size works for pest exclusion around the house?

This OLYCRAFT mesh is for crafts, not building exclusion. For mice, public health guidance recommends quarter inch hardware cloth or smaller, in appropriate gauge, installed securely at gaps and vents. National Park Service resources and the CDC reiterate quarter inch for mouse proofing and heavier gauges for larger rodents.

Can I use regular kitchen foil with polymer clay, or does it need to be special?

Regular household aluminum foil works well as a core or surface underlay. Community posts and maker tutorials recommend either tightly crumpled foil cores or a smoothly burnished foil skin under clay. The key is avoiding trapped air between clay and foil.

How do I stop sharp edges from snagging fabric or skin in wearables?

After cutting, lightly file or sand the mesh edge. For cuffs, pendants, and mask edges, many makers fold the edge under before applying clay, or encapsulate the edge inside the clay skin so the metal cannot touch skin. These are standard shop practices for expanded metal and craft meshes.

Why do some people prefer expanded aluminum mesh over woven wire for armatures?

Expanded metal is slit and stretched from a single sheet. It has no welds to pop and nothing to unravel. The diamond bonds add stiffness, openings give the clay tooth, and heat flows through during curing. That geometry is well documented in metal supplier explainers and makes expanded aluminum a studio friendly choice.

Conclusion

If you want an armature that bends easily, holds a crease, and plays nicely with polymer clay, the OLYCRAFT White Sculpting Wire Mesh 12 inch by 9.8 ft, 0.25 mm is a dependable studio staple. Its expanded aluminum pattern is cut and stretched from a single sheet, which gives you the familiar diamond openings that add stiffness without extra weight and that will not unravel during forming.

From a materials point of view, aluminum is a smart choice in mixed media. It naturally forms a thin oxide film that protects the surface in everyday environments, so your stored armatures do not rust or shed stains while you work through a project queue. For polymer-clay builds, you can bake with a metal core at standard settings. Sculpey’s own instructions recommend preheating to 275 degrees Fahrenheit, that is 130 degrees Celsius, and baking for 15 to 30 minutes for each quarter inch of clay thickness, then shielding with a loose foil tent if you see browning.

A quick reality check from the pest-control side, since many makers also repair vents and gaps at home. This OLYCRAFT roll is a craft mesh, not a building exclusion screen. When you need to keep mice out of a structure, public health guidance calls for hardware cloth with openings around one quarter inch, plus steel wool for small gaps and proper flashing at larger penetrations. Save this aluminum mesh for art, and choose the right, heavier material for rodent proofing.

Reviews

There are no reviews yet.