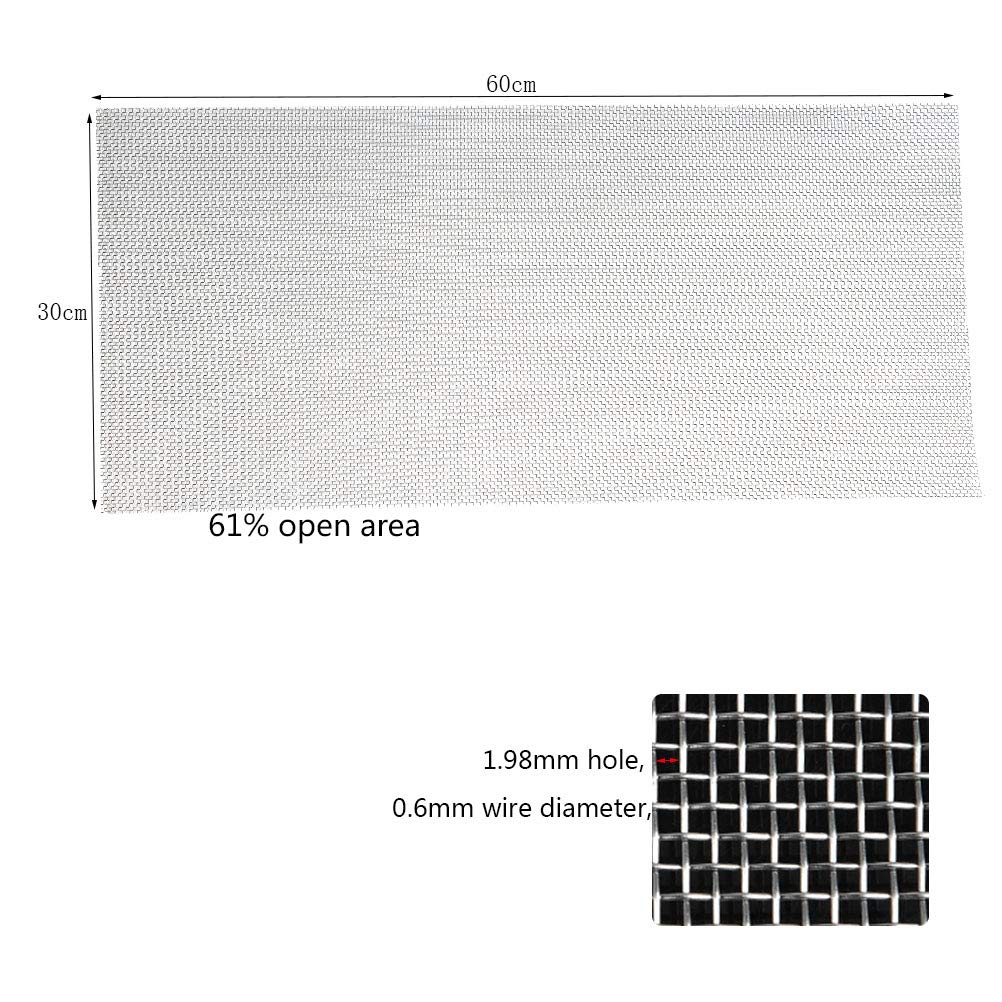

TIMESETL 304 Stainless Steel 10-Mesh Wire Sheet, 12 x 24 inches

$13.99

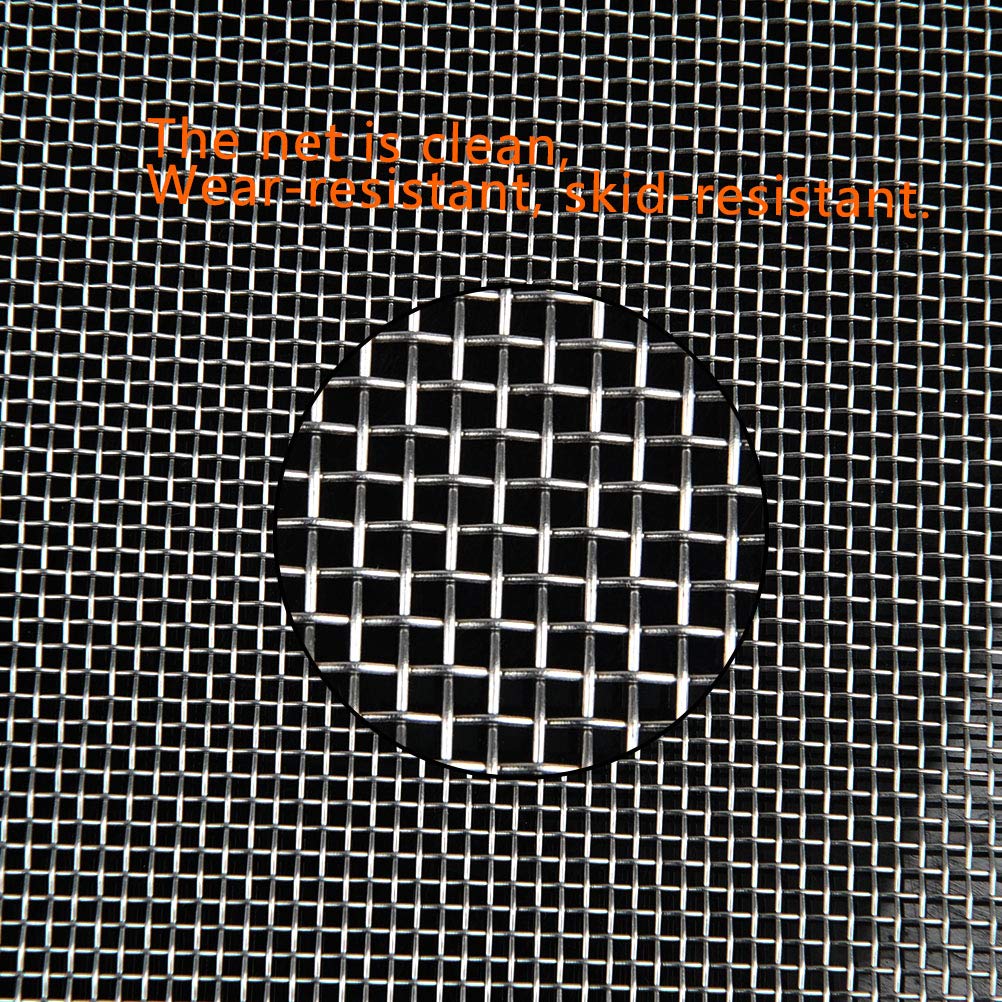

Tough, cleanable, and easy to cut, the TIMESETL 304 Stainless Steel Woven Wire 10 Mesh (12 x 24 inches) is the do-it-all panel for vents, cabinets, garden enclosures, and BBQ spark guards. The 10 x 10 weave uses 304 stainless for rust resistance and heat tolerance, with a typical opening about 0.075 inch when paired with 0.025 inch wire, giving great airflow without the fragility of fiberglass screen. Install with stainless fasteners for long-lasting rodent and ember defense around the home.

Description

If you need a tough, cleanable screen you can cut to size for real-world pest and home projects, the TIMESETL 304 Stainless Steel 10-Mesh Wire Sheet, 12 x 24 inches is a smart, durable starting point. It is made from 304 stainless steel, a workhorse alloy chosen for its corrosion resistance and heat tolerance, and the 10-mesh weave gives you roughly two millimeters of clear opening per aperture for sturdy airflow and screening in one panel.

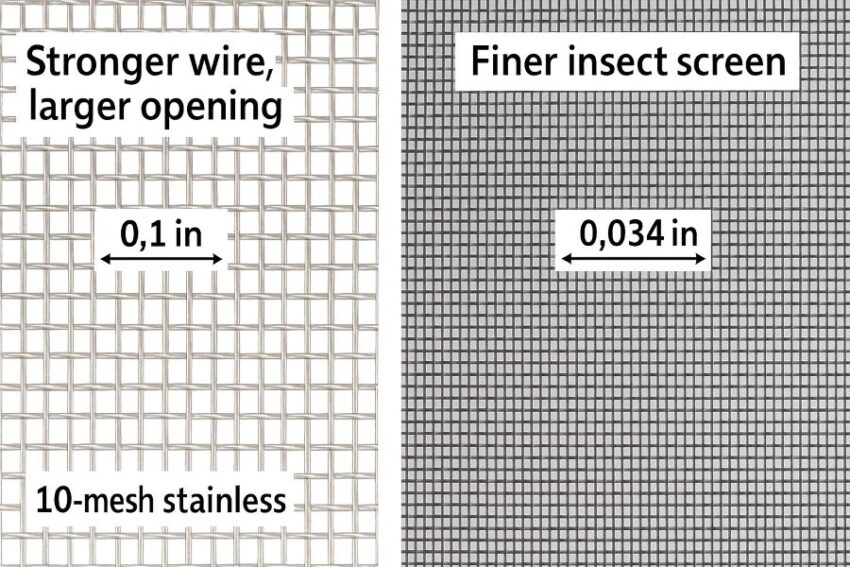

From a pest-control angle, that size and material hit a sweet spot for excluding debris and larger insects, guarding soffit or crawl-space vents, lining cabinet backs, and even building quick ember-safe spark guards at the grill, while the stainless surface resists rust in damp gardens and coastal air. Standard window insect screens are usually a tighter 18 x 16 mesh, so this 10-mesh sheet shines when you want stronger wire with bigger breathing room and easy cleaning.

Key Customer Benefits

- Stops pests without suffocating your space. The 10-mesh weave gives you openings of about 1.9 millimeters with roughly 56 percent open area, so fresh air keeps moving while you block debris, wasps, roaches, and other larger insects around vents, soffits, and cabinet backs. It is a sturdier, more open alternative to tight 18 x 16 insect screen that is common in windows.

- Real rodent-exclusion size for small gaps. Public-health guidance reminds us that mice squeeze through holes about 6 millimeters wide, and most professionals specify quarter-inch hardware cloth or finer for exclusion. This stainless steel 10-mesh is finer than a quarter-inch opening, so it is a strong choice for capping weep holes, pipe chases, and other chew-prone entry points where you still want airflow.

- Built for harsh places and hot jobs. Made from 304 stainless steel, the sheet resists rust in damp gardens and coastal air and tolerates high heat at grills or smoker intakes far better than mild steel or fiberglass screen. Industry data puts 304’s oxidation resistance up to around 870 degrees Celsius in intermittent service.

- Cuts cleanly and holds shape. Stainless woven wire trims with snips and stays flat, so you can make tidy rectangles for stainless steel window screen 10 mesh inserts, cabinet vents, or a BBQ stainless steel mesh sheet 12 x 24 grate guard without the fraying you get from softer screen cloths.

- Safer screening where embers or sparks are a concern. Wildfire and ember-resistant resources favor one-eighth inch or finer screens on vents. This 10-mesh panel has smaller openings than one-eighth inch, which helps stop ember-sized particles on attic or crawlspace vents, while you still maintain ventilation.

- A durable, chew-resistant upgrade. Compared with plastic or fiberglass, rodent-proof stainless mesh stands up to gnawing and the push-pull abuse around bins, crawlspace doors, and garden beds. Many exclusion guides and field professionals default to metal mesh for exactly this reason.

Product Description

What this sheet actually is

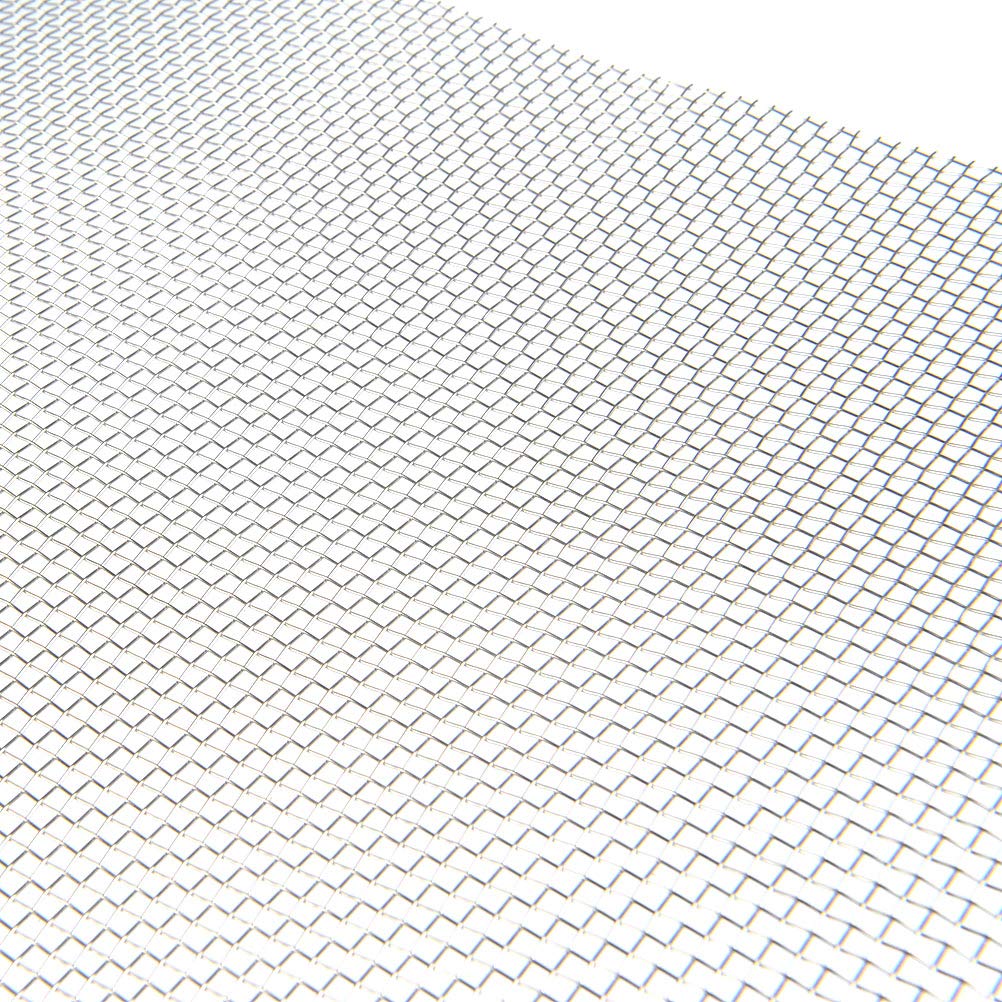

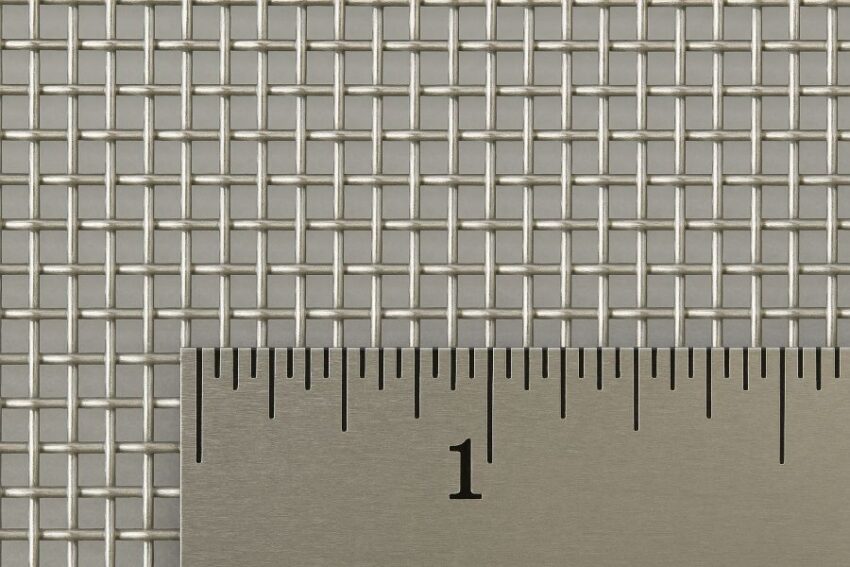

The TIMESETL 304 Stainless Steel Woven Wire 10 Mesh, 12 x 24 inches panel is a plain-weave stainless cloth with ten wires per linear inch in both directions. In practical terms, 10 mesh gives you a small grid of square openings that can pass air while stopping larger insects, grit, and embers. Because it is Type 304 stainless steel, it is non-combustible and corrosion resistant, so it holds up around grills, garden edges, soffit vents, and cabinet backs without rusting like mild steel or sagging like fiberglass screen.

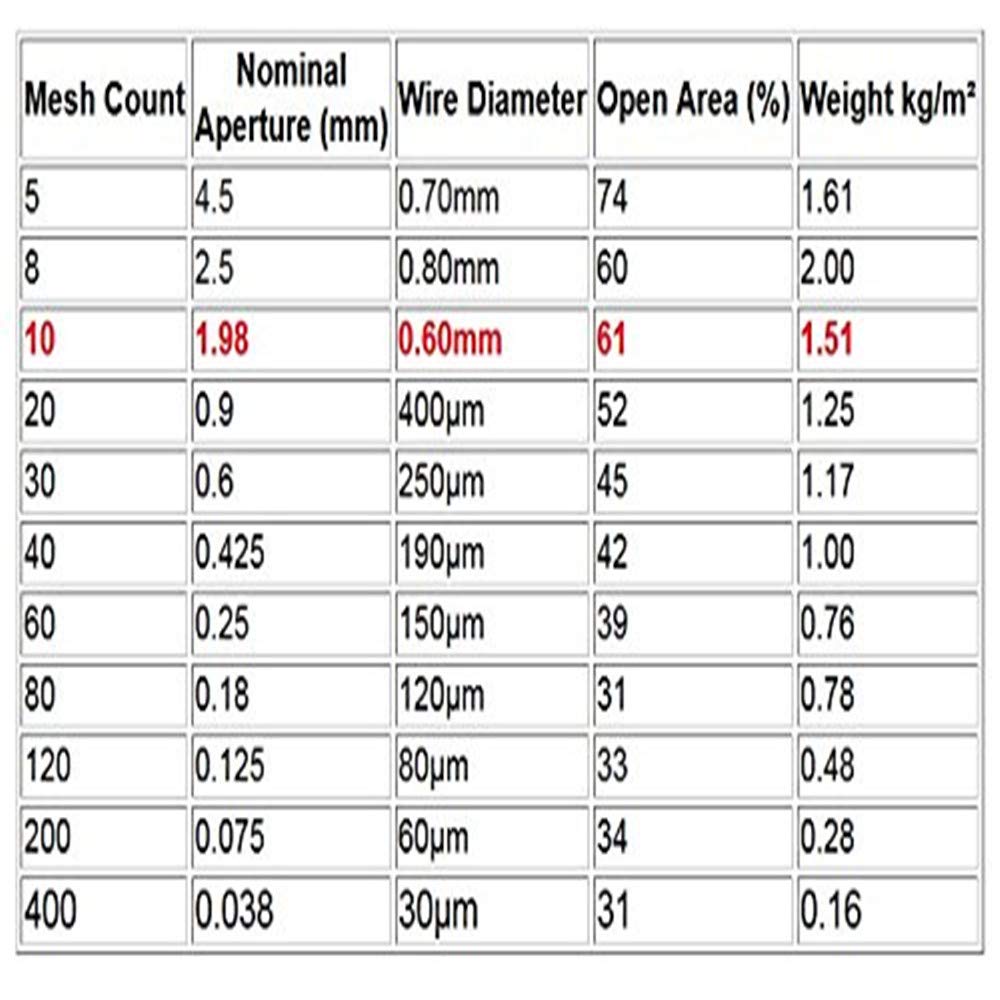

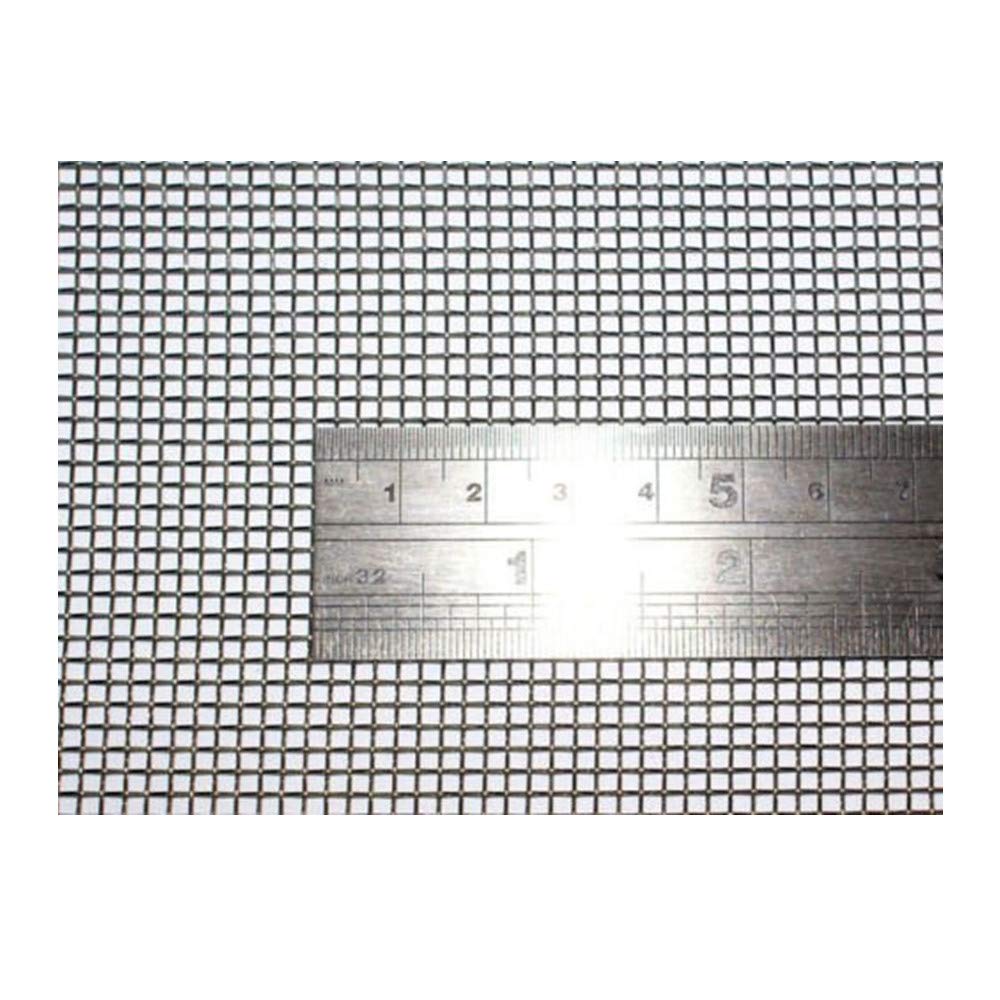

The exact opening size on 10-mesh cloth depends on the wire diameter the mill uses. Reputable catalogs show common 10-mesh builds such as 0.047 inch wire with a 0.053 inch opening or 0.025 inch wire with a 0.075 inch opening. That translates to roughly 1.35 millimeters at the tighter build and 1.9 millimeters at the more open build. Either way, you are working with a sturdy screen that still breathes.

How it works

Think of woven wire as a tiny picket fence. Each stainless filament interlaces over-under to make a stable grid. That grid creates uniform apertures that:

- let clean air move through vents and cabinets,

- stop wasps, large roaches, and wind-blown debris,

- give rodents a harder surface to chew through, and

- stand up to heat far better than plastic or fiberglass screen.

Type 304’s chemistry is the reason it behaves so well outdoors. Industry references place 304’s oxidation resistance up to about 870 degrees Celsius in intermittent service and about 925 degrees Celsius in continuous service, which is far above the temperatures that soften common household plastics.

Why this mesh is effective and different

Most window screens use 18 x 16 insect mesh in aluminum or fiberglass. That is great for mosquitoes, yet it dents, tears, and melts if you use it near hot equipment. With 10 mesh in 304 stainless, you trade a little insect tightness for a big leap in durability, chew resistance, and heat tolerance. For wildfire-aware home projects, public guidance calls for non-combustible, corrosion resistant vent screening with openings from one sixteenth to one eighth of an inch, and 10 mesh fits inside that opening range while maintaining airflow.

From a pest-exclusion standpoint, keeping rodents out is mostly about closing the small gaps. Public health sources remind us that mice can get through holes about one quarter of an inch, so covering utility chases, weep holes, and soffit penetrations with a tight stainless screen is a smart step while you also seal with metal flashing and good sealant. The stainless surface resists gnawing better than plastic cloth, and it will not become brittle in the sun.

Product Specifications

| Attribute | What you get |

|---|---|

| Product name | TIMESETL 304 Stainless Steel Woven Wire 10 Mesh, 12 x 24 inches |

| Nominal mesh | 10 x 10 wires per inch (plain weave) |

| Common build options for 10 mesh | Two well-documented builds: 0.047 inch wire with 0.053 inch opening and about 28 percent open area, or 0.025 inch wire with 0.075 inch opening and about 56 percent open area |

| Sheet size | 12 x 24 inches, about 0.186 square meters total area |

| Material | Type 304 stainless steel, often called 18-8 (about 18 percent chromium and 8 percent nickel) |

| Heat and oxidation resistance of 304 | Good oxidation resistance to about 870 degrees Celsius in intermittent service and about 925 degrees Celsius in continuous service |

| Weight reference for 10 mesh | About 1.45 to 1.60 pounds per square foot depending on mill and alloy |

| Standard that governs industrial woven wire cloth | ASTM E2016 |

| Vent ember-screen guidance for homes | Public wildfire programs recommend non-combustible, corrosion-resistant metal screen at 1 eighth inch or tighter openings for vents |

| Food-contact context | 304 stainless is commonly used for food equipment when fabricated as a smooth, cleanable surface; always follow your local code and the FDA Food Code’s requirements for food-contact surfaces |

| Safety and compliance | Non-combustible metal screen; corrosion-resistant |

| Typical uses | Vent and soffit backing, cabinet and radiator covers, weep-hole guards, small animal proofing, ember screening, BBQ spark guard and intake screens |

How to Use and Install the Mesh

Before you start

Walk the area and list the reasons you are installing the TIMESETL 304 stainless steel woven wire 10 mesh. Rodent exclusion has different priorities than ember screening or cabinet ventilation. For mice, public health guidance is clear. They can squeeze through holes about the width of a pencil, which is roughly a quarter of an inch, so aim to close every gap near that size or smaller. That includes pipe penetrations, utility chases, weep holes, gable and soffit vents, and crawlspace doors. Stainless mesh is ideal for the breathable spots where you cannot seal solid. You will still use sealants or flashing on everything else.

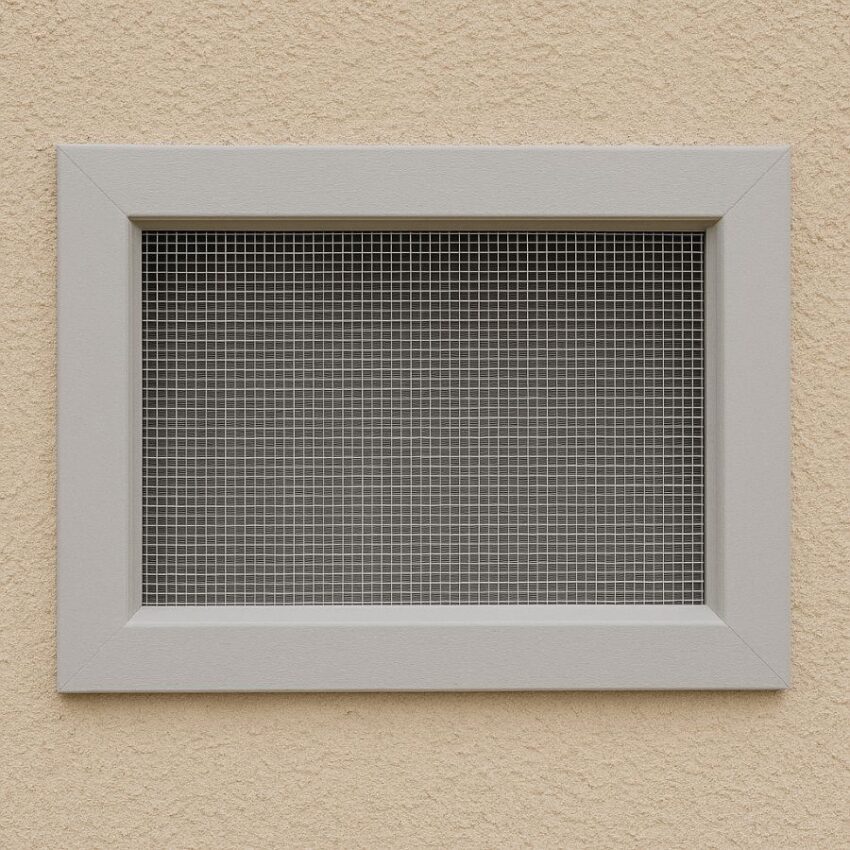

If you are upgrading vents for wildfire resilience, choose noncombustible, corrosion-resistant metal screen with an opening size from one sixteenth of an inch to one eighth of an inch. Ten mesh falls inside that range, so it can help resist ember intrusion while still allowing airflow. The key is a tight fit and noncombustible fasteners.

Tools and materials that make the work cleaner

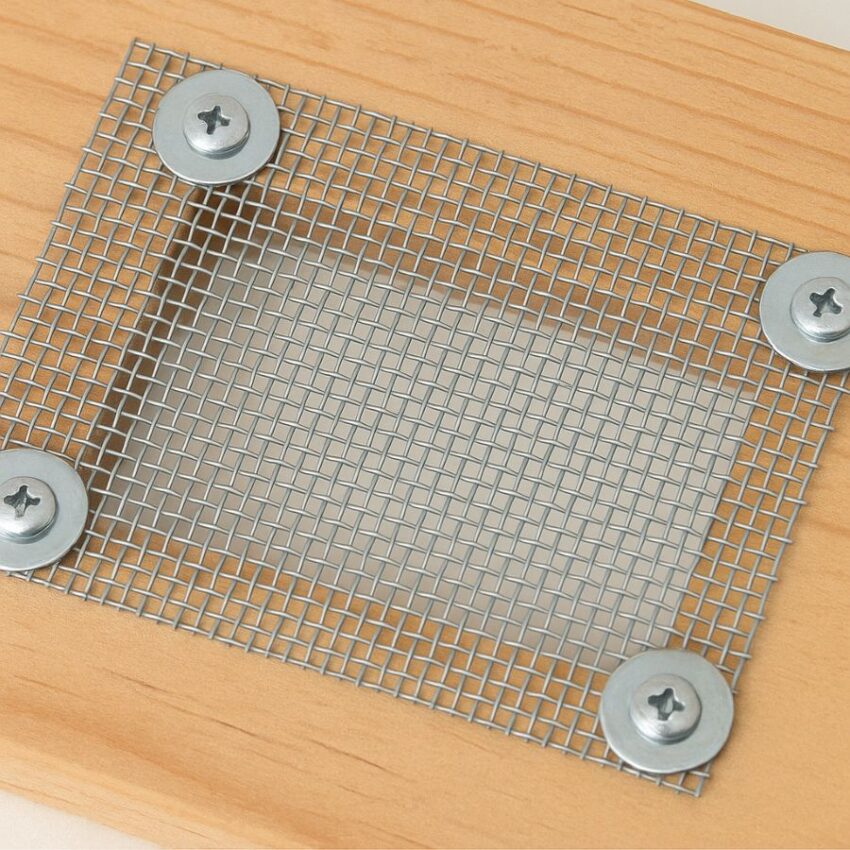

For most installs you will need aviation snips or bolt cutters, a file for deburring, a drill or driver, stainless screws, and either wide fender washers or metal strapping to spread the load along the mesh. DIYers who build animal enclosures and vent covers often combine stainless washers with coated deck screws at 6 to 8 inch spacing along a frame, or they run a continuous strap over the mesh for a very neat look. These field-tested methods help the mesh resist prying and chewing.

A quick word on safety. Freshly cut stainless wire is sharp. Wear cut-resistant gloves and eye protection while cutting and filing. If you are trimming a lot of mesh, consider heavy duty cut protection such as stainless mesh gloves or high-rated cut resistant gloves.

Measuring, cutting, and finishing the edges

Measure the opening and add at least one inch of overlap on all sides so the fasteners are not right on the edge. Mark the mesh with a wax pencil. Cut slowly along a wire line with snips to reduce stray burrs. File the cut edge until it is smooth. If the piece will be handled often, hem the edge by bending a half inch lip over on itself against a straight board. A smooth edge protects hands and gives fasteners more material to bite into. These little finish steps are the difference between a weekend patch and a long-term fix.

Fastening to wood frames and siding

For new vent screens, predrill the frame or blocking around the opening. Hold the mesh square and start at a corner. Use stainless screws with stainless or neoprene-backed washers so the load is spread and the screen cannot pull through. Many builders set a washer every 6 inches along the perimeter. If you prefer fewer visible washers, run a narrow galvanized or stainless strap over the mesh and screw through the strap every 6 to 8 inches. The strap method looks tidy and is extremely strong.

Avoid mixing stainless mesh with plain zinc plated hardware in wet areas if you can. Dissimilar metals in contact with moisture can set up galvanic corrosion, where the less noble metal sacrifices itself. If you must mix metals, isolating layers such as neoprene washers reduce that risk.

Fastening to metal vents or masonry

On sheet-metal louvers, drill small pilot holes and use stainless pop rivets with backing washers. On masonry, create a wooden or metal frame and anchor the frame with masonry screws, then attach the mesh to the frame. This prevents cracked mortar and gives you a surface you can service later.

Rodent-exclusion specifics that really work

Use the 304 stainless 10 mesh to back up any place that must breathe and that rodents target. That includes garage and crawlspace vents, around AC line sets, under-sink pipe chases, and weep holes that open into cabinets or utility rooms. Remember that mice exploit tiny openings. They often enter through vents, along utility runs, and around gaps at doors and foundations. Cover breathable spots with stainless mesh and seal solid cracks with metal flashing, mortar, or a compatible sealant. Reinspect after a week to confirm nothing was missed.

Vent and ember-screen upgrades the right way

For attic, soffit, and crawlspace vents in fire-prone regions, remove damaged screens and clean the vent body. Install corrosion-resistant, noncombustible metal mesh at an opening size that aligns with wildfire guidance, then secure it with noncombustible fasteners all around the perimeter. Keep vents clear of debris so the screen does not clog. One eighth of an inch is a commonly recommended sweet spot for airflow plus ember resistance, and ten mesh delivers that opening while staying serviceable.

Cabinet and indoor uses without the sharp edges

When you replace a cabinet back or build a radiator cover, frame the 12 by 24 inch panel with small trim or U-channel so no raw edges are exposed. A recessed frame also deters pets and kids from catching fingers on the mesh. Stainless cleans with mild detergent. Rinse and dry to maintain the bright finish.

BBQ and utility applications

For spark guards and air intakes near grills or smokers, stainless is the right call since it does not melt and it resists oxidation at temperatures that would deform plastic cloth. Mount the mesh with noncombustible hardware and keep it free of grease. The combination of heat tolerance and cleanability is why 304 stainless shows up everywhere in hot utility zones.

Maintenance that keeps it effective for years

Twice a year, brush off lint, seeds, and dust so airflow stays strong. After storms or nearby mowing, check that washers and straps remain tight and that no corners have lifted. On wildlife jobs, a one-week and one-month follow-up is smart. If you see new gnaw marks, add more overlap or switch to a heavier frame.

Stainless mesh performs best with stainless fasteners. When you mix stainless with plain zinc hardware outdoors, moisture can speed up corrosion on the weaker metal. If similar metals are not available for a given part, use isolators such as neoprene washers to break the circuit and slow the reaction.

FAQs about TIMESETL 304 Stainless Steel Woven Wire 10 Mesh

Is 10-mesh fine enough to help with mice and other pests?

Yes for rodent-exclusion on breathable openings, and yes for larger insects and debris. Public health guidance says mice can fit through a hole about the width of a pencil, which is roughly one quarter of an inch or 6 millimeters, so anything tighter is helpful on vents and utility cutouts. Typical 10-mesh 304 stainless lists an opening near 0.08 inch when paired with a lighter wire, which is much smaller than one quarter of an inch and sits in the ember-screen range used on building vents. Use it to back vents, weep holes, and pipe chases where you still want airflow.

Will 10-mesh stop mosquitoes the way window screen does?

Not fully. Standard insect screen for windows is usually 18 x 16 fiberglass or aluminum, which is tighter than 10-mesh and better for tiny insects like mosquitoes. Ten-mesh trades some insect tightness for durability, chew resistance, and airflow. If the goal is indoor mosquito control, use 18 x 16 on the window and 10-mesh where you need a tougher barrier behind it.

Is 304 stainless safe to use near grills, smokers, or hot utility areas?

For guards and intakes, yes. Type 304 stainless is a workhorse alloy with good oxidation resistance at high temperature. Materials references list service up to about 870 degrees Celsius in intermittent use, which is far above the range that deforms plastic or fiberglass screen. Keep the mesh clean and grease-free, and mount it with noncombustible fasteners. If you plan to make a cooking grate that contacts food, keep edges smooth and cleanable and follow food-contact hygiene standards. Many fabricators choose 304 for wire baskets and fixtures because it combines strength with cleanability.

What mesh opening do wildfire programs recommend for vents?

Wildfire hardening guidance from CAL FIRE recommends noncombustible, corrosion-resistant metal mesh with openings from one sixteenth to one eighth of an inch for covering attic and underfloor vents. Ten-mesh falls inside that opening window when built with common wire sizes, so it works well as an ember screen if you install it tightly all the way around with metal fasteners.

How should I cut and finish stainless woven wire without making a mess?

Pros and DIYers lean on a few repeatable tricks. For light to medium 10-mesh, aviation or tin snips and a flat file for deburring give clean edges. On heavier gauges or large cuts, people report success with bolt cutters along a single wire or with a bandsaw and fine-tooth blade when cutting circles. Whatever you use, wear cut-resistant gloves and eye protection because fresh stainless edges are sharp.

Should I use stainless screws or are galvanized screws fine?

Match metals whenever you can. Putting stainless mesh in direct contact with zinc-coated galvanized hardware in damp conditions raises the risk of galvanic corrosion on the less noble metal. If you must mix metals, use isolators like neoprene washers to reduce contact. For the longest life, use stainless fasteners with stainless mesh.

Can I cover weep holes with this mesh without blocking drainage?

Yes, with a careful install. Rodent-exclusion manuals for buildings recommend metal screening and quarter-inch hardware cloth in many locations to keep rodents out while allowing ventilation. For brick weep holes where you want smaller openings and stainless durability, cut narrow strips of 10-mesh, frame them so they do not intrude into the cavity, and avoid sealants that block water paths. This maintains airflow while keeping pests out.

Will 304 stainless rust near the coast?

Type 304 is corrosion resistant in most home and garden environments, which is why it is so common in wire cloth. In salty coastal air, it can show surface staining and pitting over time, especially if deposits are not rinsed off. Rinse periodically to remove salt and debris. If you need maximum chloride resistance, some fabricators step up to marine grades like 316 for severe exposure.

Is 10-mesh strong enough for wildlife-prone vents and cabinets?

Yes for most residential jobs. Suppliers list 10 x 10 304 stainless in multiple builds, from a light wire with excellent airflow to heavier wire that emphasizes strength. The heavier 10-mesh variants are very tough and resist prying at corners when you spread the load with washers or metal strapping. Choose based on abuse level and ventilation needs.

What is the practical difference between 10-mesh stainless and quarter-inch hardware cloth?

Quarter-inch hardware cloth has larger openings and is often galvanized steel, so it is strong and inexpensive but not as corrosion resistant as 304 stainless. Ten-mesh stainless has smaller openings and stays clean and solid in damp spots, which is why pros combine it with metal fasteners on vents, soffits, and utility chases that must breathe and also keep out pests and embers.

Conclusion

If you want a single sheet that solves a handful of real problems with one smart upgrade, the TIMESETL 304 Stainless Steel Woven Wire 10 Mesh, 12 x 24 inches is that kind of tool. It is tough and cleanable, it keeps ventilation moving, and it stands up to weather and heat where plastic or fiberglass screens give up. Type 304 stainless is widely documented for strong oxidation resistance at high temperatures, which is exactly why professionals lean on it around grills, hot utility zones, and sun-beaten vents.

From a pest-control standpoint, this mesh hits the exclusion sweet spot for the places that must breathe. Public health guidance is plain about mice and gaps the width of a pencil, about one quarter of an inch, so covering vent openings, weep holes, and pipe chases with a smaller non-combustible screen is an immediate win. Ten-mesh stainless gives you that tighter opening while staying serviceable, and it pairs well with stainless fasteners for long life.

If you live in a fire-prone area, home-hardening programs recommend non-combustible, corrosion-resistant metal mesh with openings between one sixteenth and one eighth of an inch for vents. Ten mesh falls inside that window, so you gain ember resistance without switching to a fragile ultra-fine screen. And if your goal is just a sturdier replacement for cabinet backs or radiator covers, this sheet is easier to clean, less likely to dent, and much more heat-tolerant than typical 18 x 16 insect screen, which is the standard for windows but not for high-abuse or high-heat spots.

Reviews

There are no reviews yet.