2-Strip Aluminum Automatic Door Bottom, 36-inch Surface-Mount Drop Seal

$69.99

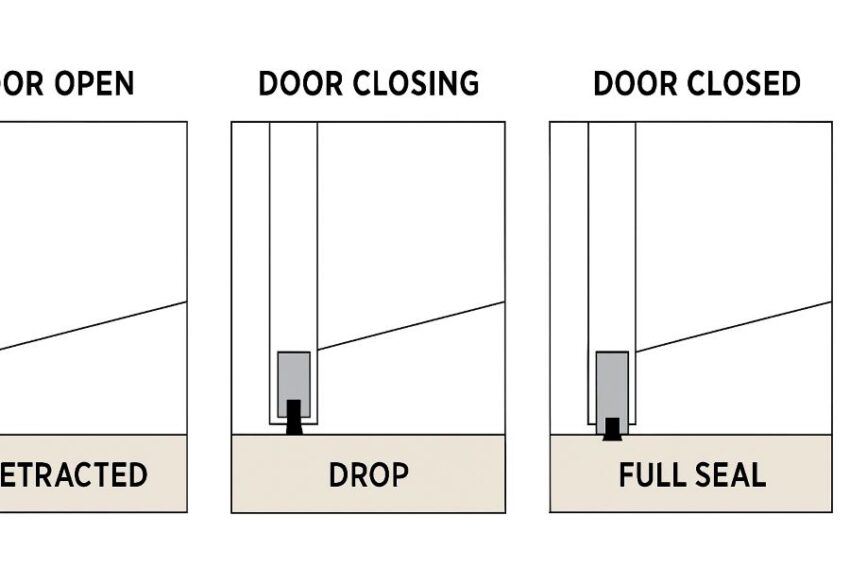

Stop the sneaky gap under your door with the 2-Strip Aluminum Automatic Door Bottom, 9/16 in. W x 36 in. L x 1-3/8 in. H, surface-mounted in natural aluminum. When the door closes, a small plunger lowers the drop seal to the floor for a tight line against drafts, dust, light, and noise. Open the door and the seal lifts clear, so there is no dragging on wood or tile. If you can see daylight at the threshold, this style of weatherstripping is a proven fix, and pairing it with a low threshold makes the seal even better.

Description

If tiny drafts, dust, and the odd ant keep sneaking under your door, a regular sweep usually helps for a while, then it drags or warps and you are back to square one. The 2-Strip Aluminum Automatic Door Bottom, 36-inch Surface-Mount Drop Seal solves that everyday problem with a smarter “drop-seal” mechanism that lowers to the floor only when the door closes, then lifts clear as you open it, so it seals better and wears less. This style of seal is widely used in professional weatherization and acoustic work because the internal plunger lowers a compressible insert to block air, light, dust, insects, and noise at the threshold, a design documented by door hardware makers and trade guides.

Unlike a basic fixed sweep, an automatic door bottom is built around a concealed actuator that presses against the jamb at closing, which then drops the seal evenly along the entire width for a tight, consistent seal on level or slightly uneven floors. That difference is why these are preferred for energy efficiency and sound control projects, and why they are covered under the BHMA A156.22 gasketing standard that evaluates air infiltration, acoustics, smoke resistance, and durability.

Key Customer Benefits

- Cuts drafts and trims energy waste at the biggest leak point. Exterior doors are frequent culprits for air leakage that drives up heating and cooling costs. Effective weatherstripping at the threshold reduces that loss by sealing the moving gap where conditioned air escapes. The U.S. Department of Energy highlights doors as a significant source of air leakage, and utility programs cite estimates that around one tenth of whole-home leakage can occur around doors, so tightening this gap matters.

- Blocks pests before they ever cross the line. When the door closes, the drop seal engages and closes the clearance at the floor, which is where insects and rodents slip in. University entomologists note that insects can enter through gaps as small as one sixteenth of an inch, mice through a quarter-inch, and rats through a half-inch. Closing that daylight at the sill is one of the most reliable IPM steps you can take.

- Quieter rooms thanks to a sealed door bottom. The gap under a door is often the largest sound leak. Acoustic guidance recommends a proper drop seal at the threshold, ideally paired with a threshold plate, to improve isolation and reduce flanking noise. Research and manufacturer data show that drop seals are chosen specifically to limit sound transmission at the door bottom.

- Smooth operation on uneven floors. Unlike fixed sweeps that drag, the surface-mounted automatic door bottom uses a side plunger to lower the seal as the door latches, then lifts it clear when you open the door. That self-adjusting “drop” action keeps the seal in contact on slightly out-of-level floors without adding opening resistance or wearing out the insert.

- Built to recognized performance standards. Automatic door bottoms are covered by ANSI/BHMA A156.22, which evaluates smoke and air infiltration, acoustic properties, energy performance, and durability. At the top durability grade, products are cycle-tested up to one million operations with strict limits on operating force and seal contact. Choosing hardware designed to this standard gives long-term confidence.

- Cleaner thresholds and less maintenance. Because the seal raises off the floor when the door opens, it avoids sweeping grit across the sill and reduces fraying or tearing that is common with fixed brushes or rubber strips. The result is a neater entry and fewer replacements over time, especially in busy households or light commercial spaces.

Product Description

What this product is

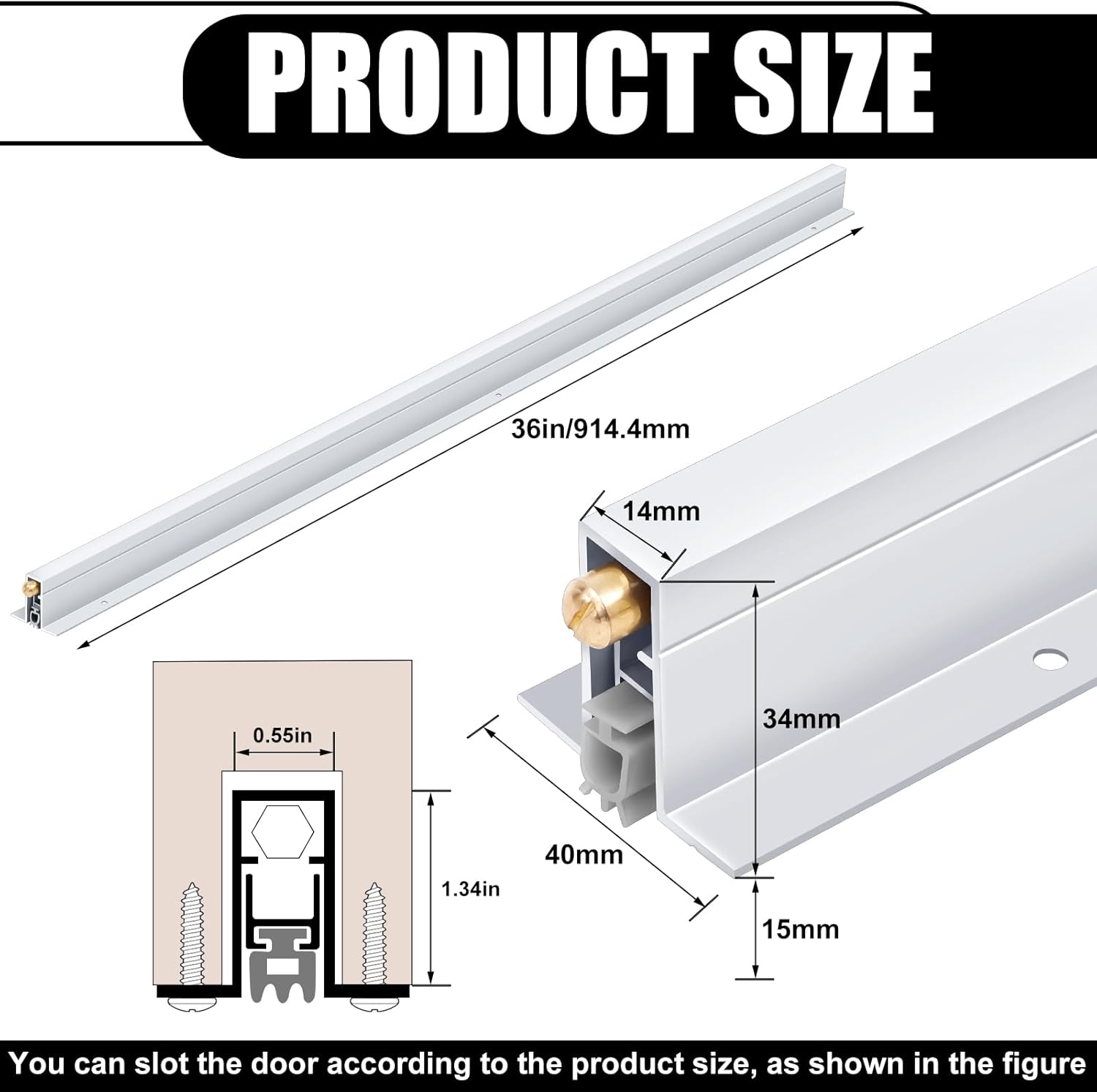

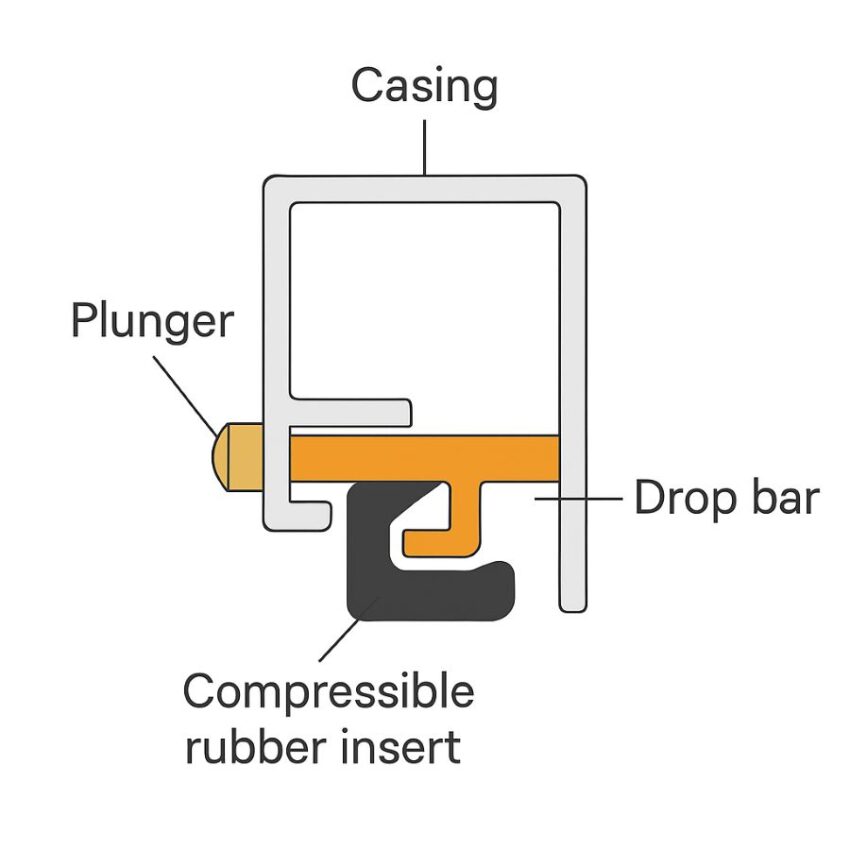

The 2-Strip Aluminum Automatic Door Bottom, 36-inch Surface-Mount Drop Seal is a drop-seal that closes the gap at the floor only when the door latches. Inside the aluminum case is a spring-loaded bar and a compressible insert that create a uniform seal against the threshold or finished floor, which helps with drafts, dust, insects, and hallway noise. Dimensions like 9/16 inch by 1-3/8 inch are common for automatic door bottoms in this class, which keeps the profile slim enough for residential doors while still accepting durable inserts such as silicone or neoprene.

How it works

As the door closes, a small plunger on the hinge side contacts the jamb and activates an internal spring. That action drops the concealed bar straight down so the two sealing strips compress evenly along the floor. When you open the door, the bar lifts clear again, so there is no dragging across tile or wood and far less wear compared with a fixed sweep. Trade references describe the same sequence, noting the scissor-like motion of the mechanism and the benefit of a tight seal that retracts during opening.

Why it is effective and different

A gap at the door bottom is one of the largest pathways for air and sound. The U.S. Department of Energy recommends appropriate sweeps and thresholds to reduce air leakage, and notes that weatherstripping is a fast payback upgrade when you are sealing a home. Automatic door bottoms add a precision element to that advice because they press the gasket into the floor only when needed, which improves contact on slightly uneven sills and reduces long-term friction. For pest control, sealing low gaps matters, since Building America guidance documents that mice can enter through openings as small as one quarter of an inch and rats through one half of an inch. Closing the daylight at the threshold is a core integrated pest management step.

For sound, door seal kits from acoustic suppliers consistently call out the under-door opening as a critical leak path. Best practice is to pair an automatic drop-down seal at the bottom with perimeter gasketing and, when practical, a saddle threshold, which is why acoustic kits often include an automatic door bottom as the centerpiece of the package.

Durability is another differentiator. Automatic door bottoms that are certified to ANSI/BHMA A156.22 are tested for air infiltration, energy performance, acoustic properties, and life cycle. Grade 1 products in this category are cycle-tested to one million operations, with limits on operating force and on how much sealing contact they must retain after the test. Many well known surface-mount and mortised models publish compliance to A156.22 and related ASTM tests, which gives you a predictable performance baseline.

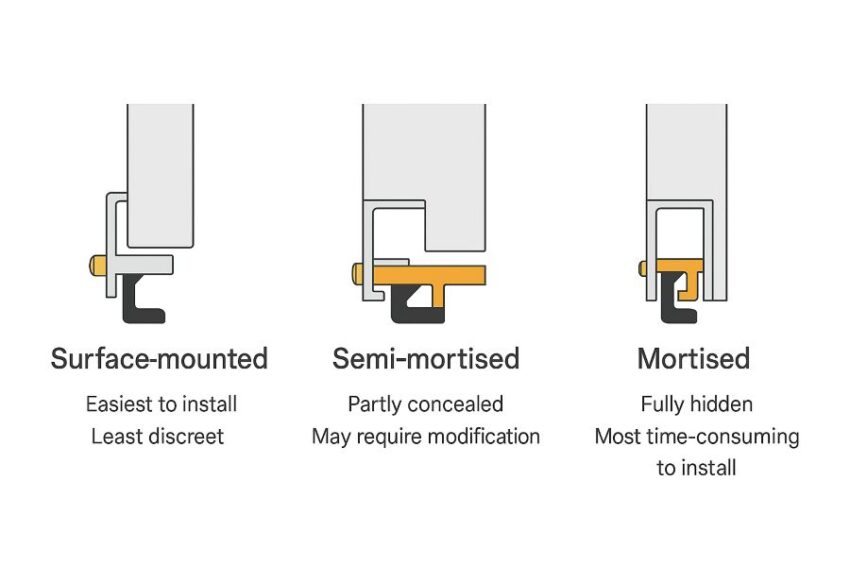

Where surface-mounted fits vs mortised styles

You can install drop seals in three ways, surface mounted on the interior face, half-mortised, or fully mortised into the bottom edge. Mortised versions often create the most continuous seal because they span the full width of the door and sit flush, although they require door prep. Surface-mounted versions like this one are popular because they install with basic tools and still deliver a strong seal, especially when paired with a threshold. Trade guides compare the options in exactly these terms, which helps homeowners choose the balance of performance and simplicity that fits their project.

Product Specifications

| Attribute | What to Know |

|---|---|

| Form factor | Surface-mounted automatic door bottom, standard 36 inch length, slim body about 9/16 inch wide by 1-3/8 inches high. This size is widely sold in natural aluminum finish. |

| Housing material | Clear anodized aluminum, sometimes offered in dark bronze or other anodized finishes depending on the line. |

| Insert options | Common inserts include neoprene sponge, silicone, or nylon brush. Neoprene and silicone are favored for tight weather and acoustic seals, while brush is used near carpet. |

| Maximum drop | Typically up to three quarters of an inch, with some heavy-duty models rated to about one inch effective drop. |

| Mounting side | Push side of the door is standard for surface-mount styles. |

| Door thickness compatibility | Commonly compatible with 1-3/4 inch and 1-3/8 inch doors, with alternate end plates as needed. |

| Field trimming | Many models are supplied slightly long and are field-trimmable. Typical cut-down allowances are one half inch on short lengths and up to one and one half inches on 20 inch and longer. |

| Included hardware | End caps often furnished and mounting screws included with most kits. |

| Recommended threshold pairing | Best performance when paired with a threshold. Manufacturers explicitly recommend using a threshold for maximum sealing and suggest brush inserts where carpet is present. |

| Standards and listings | Products in this category are evaluated to ANSI and BHMA A156.22 gasketing requirements. Many models also list UL10C fire, UL1784 air-leakage smoke, and ASTM E283 air infiltration. Check the specific model’s data sheet. |

| Acoustic use | Frequently specified in sound control door kits. Some surface or mortised ADBs report zero loss up to doors rated around STC 56 when installed per instructions. |

| Durability | Life-cycle claims vary by model from about one million to several million operations in manufacturer testing. |

| Finish color shown | Natural aluminum, also called mill or clear anodized, matches most commercial thresholds. |

| Use cases | Weather and energy sealing at the door bottom, pest exclusion at small gaps, light and dust control, and improvement of speech privacy when combined with perimeter seals. |

| Safety and usage notes | Confirm swing clearance and latch operation after installation. Avoid settings where the seal must drag on deep carpet, or switch to a brush insert as manufacturers advise. Pairing with a threshold improves both sealing and service life. |

How to Use and Install the Automatic Door Bottom

Before you start

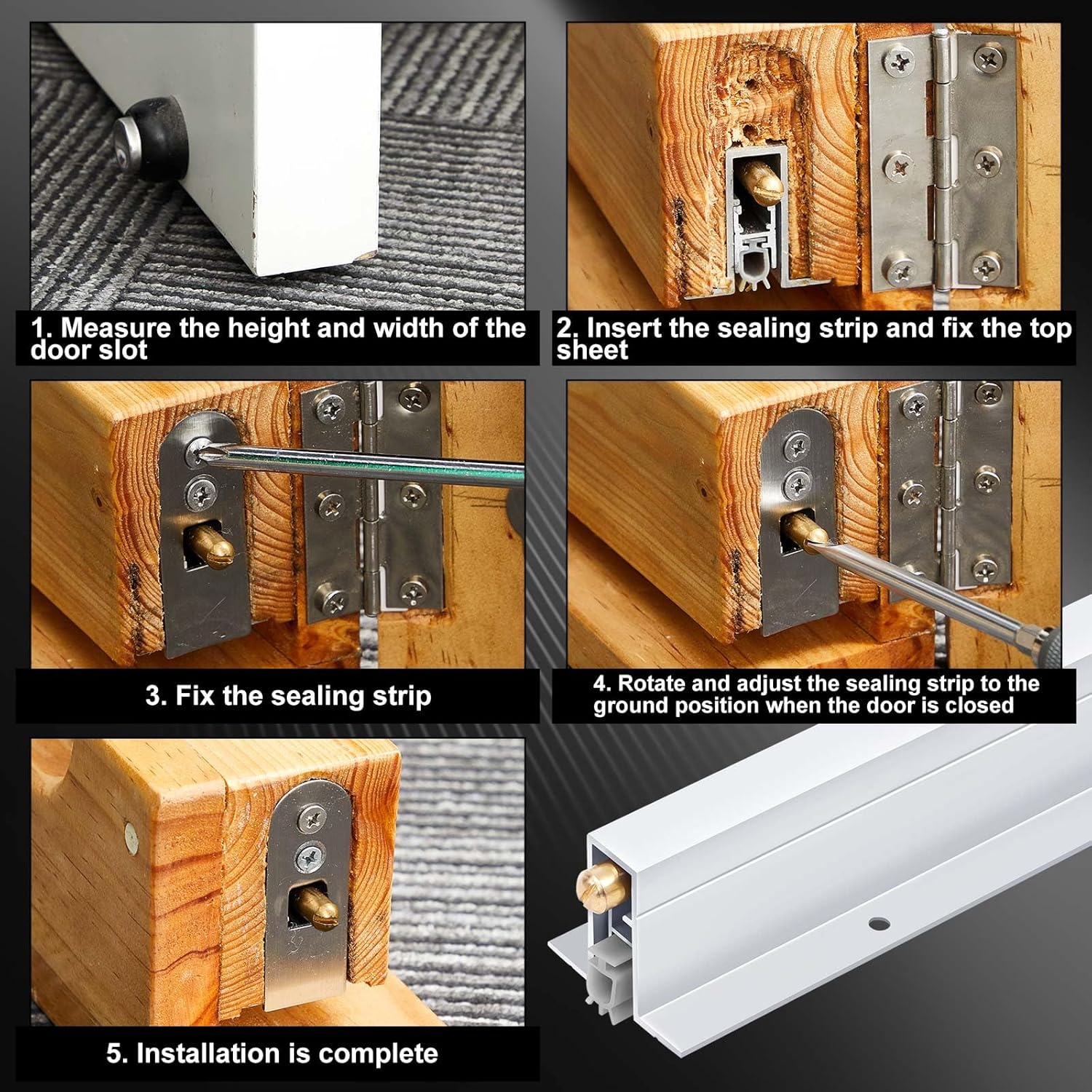

An automatic door bottom works best when the door is square, the hinge screws are tight, and the threshold is smooth. Plan to mount it on the push side of the door with the plunger on the hinge side. That layout makes the drop bar lower evenly when the door latches and then lift clear when you open the door. Several manufacturers specify this exact orientation for surface-mounted models.

Tools and materials: tape measure, pencil, miter box or fine-tooth hacksaw, drill and bits, countersink, screwdriver or driver, safety glasses, vacuum, and a file. If your frame is wood, keep a short No. 10 flat-head screw handy for the jamb where the plunger touches so the wood does not dent over time.

Step 1. Measure the door and plan your cut

With the door closed, measure the net width of the door face. Most surface-mount units are installed flush with the bottom edge of the door with about 1/16 inch clearance at each end, so subtract that when you mark your cut. Always cut from the non-plunger end and respect the maker’s maximum cut allowance. Typical guidance is that 36 inch and longer units can be trimmed up to about 4 inches, while shorter units should not be field cut and should be ordered net length.

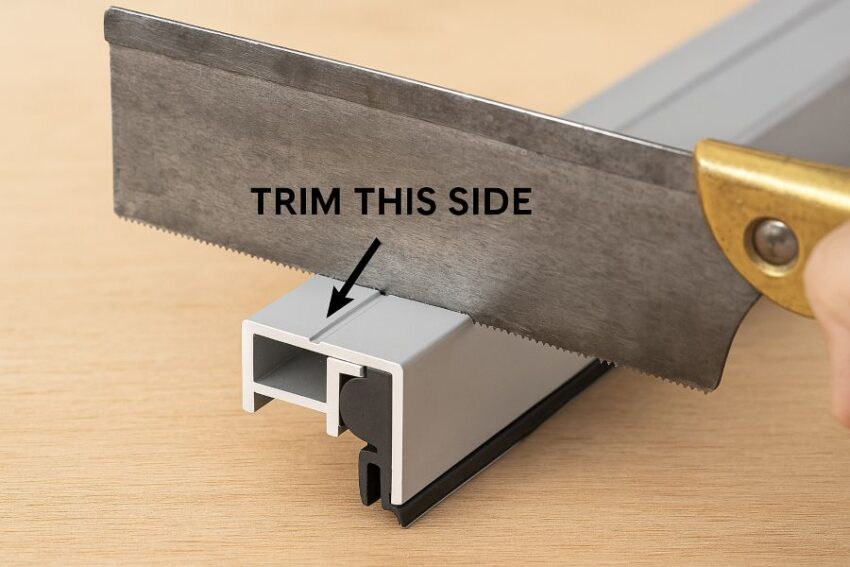

Step 2. Trim the housing cleanly

Secure the piece in a miter box to keep the cut square. Extend the drop bar per the instructions if required, then saw slowly. Deburr with a file and vacuum aluminum chips so they do not foul the mechanism. Do not shorten the plunger side and do not cut the adjusting rod. Multiple manufacturer sheets repeat these cautions.

Step 3. Test-fit and mark holes

Hold the door bottom flush with the door’s lower edge on the push side, with the adjusting block or plunger toward the hinge edge. Center it so you keep that 1/16 inch relief at each end. Mark the screw holes. Pilot-drill per the instructions, typically with a 7/64 to 11/64 inch bit depending on model. Avoid over-tightening the screws, which can bow the case.

Wood frames: set a small flat-head screw at the jamb point where the plunger contacts. This spreads load and prevents a dent that could shift your adjustment later.

Step 4. Fasten the unit

Fasten the center screw first, then the remaining screws. Snug is the goal. You should be able to open and close the door freely with no rubbing because the bar retracts as the door opens.

Step 5. Adjust the drop for a perfect seal

Close the door. Turn the adjusting rod on the plunger end in small increments until the seal just kisses the floor or threshold from hinge side to lock side. On common models, clockwise reduces the drop and counter-clockwise increases it. Aim for positive contact without drag. If you need a deeper contact surface on an out-of-level sill, pair the seal with a low saddle threshold.

Step 6. Confirm accessibility and clearance

If the doorway is part of an accessible route, thresholds should not exceed 1/2 inch in height in new construction and any height above 1/4 inch must be beveled. Checking this now avoids creating a trip edge or excessive force at the seal. This comes from the U.S. Access Board’s guide to the ADA Standards, Section 404.2.5.

Step 7. Field check your seal like a pro

Do two fast tests after adjustment. First, the flashlight test at night to spot any light peeking under the door. Second, the paper or smoke-pencil test to see if air moves at the threshold. The U.S. Department of Energy suggests simple visual and smoke methods to find door leaks, and energy auditors use the same approach during blower-door testing.

Using the seal day to day

There is nothing to operate. When the door closes, the drop bar engages against the floor or threshold. When you open the door, it retracts so it does not drag on tile or wood. If you notice rubbing sounds later, give the adjusting rod a small turn to restore the light contact you set on day one. Manufacturers expect occasional seasonal tweaks as humidity and flooring change.

Maintenance and seasonal tuning

Keep the sill clean. Grit shortens the life of any gasket. Vacuum the threshold and wipe the insert with a damp cloth a few times a year. If the door starts to leak light at one corner, add a quarter-turn of adjustment until contact returns. If your undercut is larger than the device’s maximum effective drop for the model you bought, add a saddle threshold so the seal is not over-extended. Catalogs and data sheets list typical effective drops of 1/2 to 3/4 inch, and some heavy-duty units are rated to about 7/8 inch.

Common issues and Solutions

Uneven seal line or a small gap at the lock side: Start by verifying the plunger is on the hinge side and the case is flush with the bottom of the door. Then increase the drop slightly. If the floor is crowned, a thin threshold shim under the low side can help. Instruction sheets show the correct orientation and the 1/16 inch end clearances that keep the bar centered.

Seal drags on the floor when opening: Back off the adjusting rod a fraction of a turn. The drop should be just enough to seal without friction. Maker instructions emphasize light contact and no over-tightening of mounting screws.

Wood jamb denting at the plunger contact point: Install a small flat-head screw or the furnished strike plate where the plunger lands. This is an explicit step in several installation guides for wood frames.

Need to shorten after installation: Remove the unit and cut only from the non-plunger end within the stated limit. Lock the drop bar extended per the instructions before trimming, then deburr and reinstall.

When to pair with a threshold

If your door has a deep undercut or an uneven floor, add a low saddle threshold under the swing path. It gives the seal a smooth landing and helps with accessibility when you keep the height within the 1/2 inch ADA limit. Many acoustic and gasketing guides recommend thresholds with automatic door bottoms for the best, long-term seal.

You now have a pro-level installation. In everyday use, the seal drops quietly at close, blocks drafts and pests at the gap, and clears the floor whenever the door swings. If you would like, tell me your door type and flooring, and I will tailor the adjustment steps to your exact setup.

Frequently Asked Questions

1) What is an automatic door bottom, and how is it different from a regular sweep?

An automatic door bottom is a surface- or mortise-mounted bar with a spring-loaded “drop” seal that lowers when the door closes and lifts when the door opens. A regular sweep stays in contact with the floor all the time, which can drag and wear. The drop action gives you a tighter seal for drafts and sound without scraping your floor, which is why acoustic suppliers and hardware guides recommend automatic door bottoms for performance sealing.

2) Which side of the door does it go on?

For a surface-mounted model like this 2-Strip Aluminum Automatic Door Bottom, mount it on the push side with the plunger toward the hinge side. That way the jamb presses the plunger at close, the seal drops evenly from hinge to latch, and it retracts when you open the door. Multiple installation sheets show this exact orientation.

3) Can I cut a 36 inch unit to fit my door?

Yes, most brands allow modest field trimming, but only from the non-plunger end and within the maker’s limit. Typical guidance says 36 inches and longer can be cut up to about 4 inches, while shorter lengths should be ordered net size. Always confirm your model’s label before cutting.

4) How much drop can the seal cover under my door?

Max drop depends on the model. Common surface-mounted units list effective drops around 3/4 inch, and some heavy-duty versions publish maximum drops up to 7/8 inch. If your undercut is bigger, add a low saddle threshold so the seal lands on it without over-extension.

5) Do I need a threshold, and what if I have carpet?

A threshold is recommended for the best seal and to give the automatic drop seal a smooth landing. Where there is no threshold over carpet, manufacturers recommend switching to a nylon brush insert, since a rubber bulb will not glide over pile cleanly.

6) Will this actually help with noise between rooms?

Yes, sealing the door bottom is a key step in sound control because the under-door gap is usually the largest acoustic leak. Acoustic suppliers specify automatic drop seals for the bottom, typically paired with perimeter gaskets.

7) Will it help with pests too, or do I still need traps?

Closing the daylight at the threshold is one of the simplest exclusion steps. University entomology guidance notes that insects fit through gaps as small as 1/16 inch, mice through 1/4 inch, and rats through about 1/2 inch. Seal first, then use baits or traps only where needed.

8) Can I install it without removing the door from the hinges?

For surface-mounted automatic door bottoms, yes. Trade installation guides explain that surface-mount units can be installed with the door in place. Mortise styles usually require door removal and routing.

9) Is a surface-mounted automatic door bottom OK on a fire-rated or smoke door?

Only if the specific model is listed for that use. Smoke and draft control doors are tested to UL 1784, and hardware for fire doors must be listed to UL 10C or NFPA 252. Check your product’s data sheet and listings before installing on a rated door.

10) Is a full-width surface-mounted bar allowed by accessibility rules on the push side?

Be careful here. The ADA requires the push side of a swinging door to have a smooth surface within the bottom 10 inches of the door, with any seams within 1/16 inch of the plane. A surface-mounted automatic door bottom spanning the full width may be considered out of compliance because it creates a projection on that lower push-side surface. If accessibility applies to your opening, choose a mortised or carefully detailed solution, or consult your local authority.

11) How do I adjust it so it seals without dragging?

Close the door and turn the adjusting rod at the plunger end a little at a time. On many models, turning right reduces drop and turning left increases drop. Aim for contact that just touches the floor or threshold. Do not overtighten mounting screws.

12) How can I test whether I sealed the bottom gap well enough?

Use simple field checks from energy-efficiency guides. At night, try the flashlight test to look for light under the door. Or use a smoke pencil or incense during a blower-door or fan-on test to see if air pulls at the threshold.

13) How long do quality automatic door bottoms last?

Look for products that comply with ANSI/BHMA A156.22. Grade 1 automatic door bottoms are cycle-tested to one million operations, and must still operate within force limits while keeping most of their sealing contact after the test. That benchmark is a good proxy for durability.

14) Which insert should I choose, silicone, neoprene, or brush?

Choose the insert for your floor and goal. Neoprene and silicone bulb inserts are common for energy and acoustic sealing over hard floors. Brush inserts are favored where the seal must clear carpet. Neoprene is abrasion resistant, while brushes are not the first choice for sound isolation but glide over carpet better.

15) Will it work on slightly uneven floors or a sloped sill?

Yes. Automatic door bottoms drop from the hinge side and pivot along the floor, which lets the insert conform to small variations. If the floor is very irregular or the undercut is large, add a low saddle threshold, then tune the adjustment so the seal contacts evenly.

Conclusion

Sealing the gap at the bottom of a door is one of those small upgrades that quietly pays you back every day. The 2-Strip Aluminum Automatic Door Bottom, 36 inch surface-mount drop seal closes the place where energy, dust, bugs, and hallway noise slip in. That is not just a hunch. The U.S. Department of Energy flags exterior doors as frequent sources of air leakage and specifically recommends using the right sweeps and thresholds to cut those losses. When this drop seal lowers only at close, you get a tighter seal with less wear and a more comfortable home.

From a pest control standpoint, closing the daylight at the threshold is textbook exclusion. University and federal resources note that insects can get through gaps as small as 1/16 inch, mice through about 1/4 inch, and rats through about 1/2 inch. An automatic drop-down door seal pairs a firm contact line with easy daily use, which is exactly what you want at a busy entry.

Related products

-

Sale!

M‑D Heavy‑Duty 36″ Bronze Aluminum Door Sweep with Rubber Seal

$19.88Original price was: $19.88.$15.58Current price is: $15.58. Buy Now -

Sale!

Garage Door Brush Seal Roll‑Up Kit – 4 Sets

$39.99Original price was: $39.99.$37.99Current price is: $37.99. Buy Now -

Pemko 36″ Aluminum Brush Door Sweep with Gray Nylon Brush

$20.39 Buy Now -

M‑D 36″ Aluminum U‑Shape Screw‑On Under–Door Seal with Kick Plate

$32.90 Buy Now

Reviews

There are no reviews yet.