3M P100 Respirator Filter 2091 for Lead, Asbestos, Arsenic & More

$215.99 Original price was: $215.99.$181.00Current price is: $181.00.

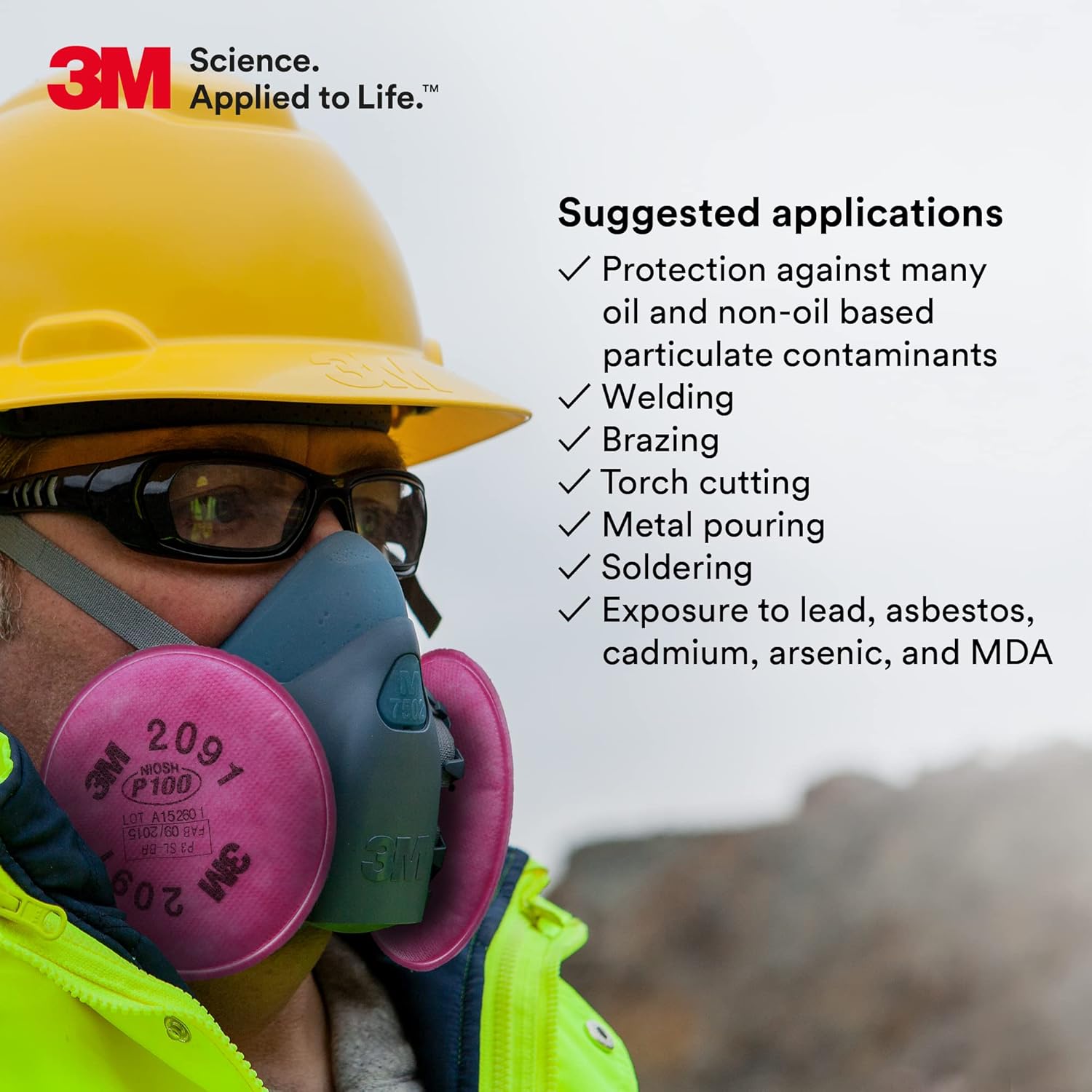

Breathe easier and tackle your toughest jobs with confidence, each 3M P100 Respirator Filter 2091 (50 Pairs) offers a high-performance defense against oil and non-oil particulates, including lead, asbestos, arsenic, cadmium, mold, and silica. These magenta‑banded, bayonet-style filters pop right onto your compatible 3M respirator and deliver a full 99.97% filtration efficiency; the kind of reliable protection you’ll actually notice when you’re scrubbing floors, reclaiming a dilapidated attic, or sanding off old paint. Grab a box and feel the peace of mind every time you work in harsh environments.

Description

Imagine tackling a moldy attic, sanding lead paint, or welding in that cramped garage, where even a single breath can carry hidden dangers. That’s when the 3M P100 Respirator Filter 2091 (50 Pairs) steps in, offering serious protection against oil- and non-oil-based particles like asbestos, lead, arsenic, cadmium, and MDA. Think of it as your trusted ally when the air around you gets rough and nothing but full-throttle safety will do.

Key Customer Benefits

- Rock-solid protection (99.97% efficiency): These filters trap nearly every airborne particle oil or non-oil including asbestos, lead, arsenic, cadmium, and MDA; giving you peace of mind even in the dirtiest environments.

- Breathable comfort for long shifts: Featuring 3M’s proprietary Advanced Electret Media (AEM), these filters breathe easy and don’t weigh you down, even during full-day mold remediation or sanding work.

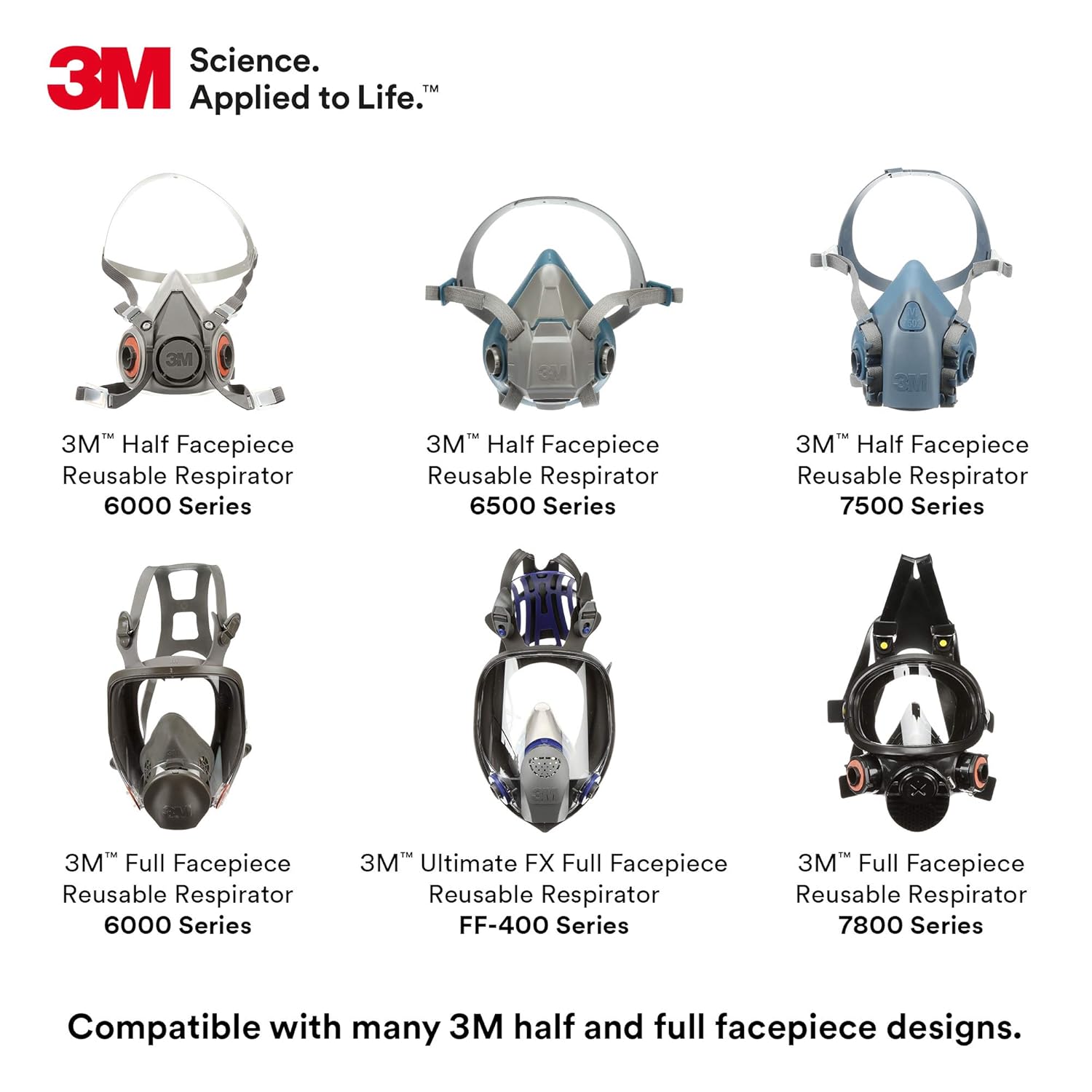

- Easy to swap and universally usable: Thanks to the quarter-turn bayonet design, switching filters is lightning-fast. They fit most 3M half and full face respirators, saving you the hassle of stocking multiple filter types.

- Built tough to match real-world demands: Flame-resistant, water-resistant, and abrasion-resistant, they’re designed for rugged environments, from metal pouring to welding to pesticide application.

- Engineered for workplace compliance: NIOSH-approved for up to 10× OSHA PELs on half-face and 50× on full-face respirators, so you can trust they meet critical safety standards.

Product Description

Let me tell you a story: last year, a renovation contractor I know, “Sam,” inherited an old house with flaky lead paint and hidden asbestos in the attic insulation. He wasn’t worried about the mess but one day, he felt gritty grit in his throat. A few hours into the cleanup, the scratchy throat turned into a relentless cough. That’s when he reached for the 3M P100 Respirator Filter 2091 (50 Pairs). Within minutes, he noticed the air cleared, his breathing eased, and he felt in control again. That’s what these filters do: they give you back confidence.

What the product is

These aren’t just filters, they’re a line of defense. The 3M 2091 P100 filters are high-performance, magenta-banded, bayonet-style particulate filters. They’re NIOSH-approved to block both oil and non-oil particles, and they remove at least 99.97% of airborne contaminants, anything from fine silica dust to mold spores, asbestos, lead, arsenic, cadmium, and MDA, making them ideal for heavy-duty jobs like those in Sam’s renovation saga.

How it works

At the core is 3M’s Advanced Electret Media (AEM), a lightweight, electrostatically charged filter layer that traps particles through impaction, interception, diffusion, and electrostatic attraction. Despite this power, breathing stays surprisingly easy, even in long sessions, thanks to thoughtful material engineering and slim design.

What sets it apart

- Bayonet design and universal fit: Quarter-turn lock-on installation works with most 3M half- and full-face respirators (6000, 7000, 7500, 7800, FF-400, plus 3M Scott AV-3000), simplifying inventory and training for professionals.

- Rugged in the field: Flame-resistant, water-resistant, robust, even in welding or metal pouring operations. The shell is built tough for real worksite abuse .

- Compliance you can trust: Meets NIOSH P100 standards and supports up to 10× OSHA PEL on a half-mask and up to 50× on a fit-tested full facepiece, meeting serious safety regulations with ease.

A real-life example

Imagine dealing with asthma-triggering dust in a chicken farm cleanup, deep in the coops, the fine dust is suffocating. A friend in agro-sanitation put these filters on her 6000-series half mask. She told me, “For once, I could breathe through my nose after hours of work. It was a game changer.” That’s not marketing fluff, it’s real relief.

With the 3M P100 Respirator Filter 2091, you’re not just buying filters; you’re investing in cleaner, safer breathing when it matters most. And when your lungs feel the difference, everything else becomes easier.

Product Specifications

| Specification | Detail |

|---|---|

| Filter Type | P100 (oil-proof, per NIOSH) – captures ≥ 99.97% of particles ≥ 0.3 µm |

| Media | Advanced Electret Media (AEM); no fiberglass |

| Connection Style | 3M quarter‑turn bayonet, magenta-coded |

| Compatible Respirators | 3M 6000/6500/7500/7800S/FF-400, with adapter also fits 5000 & 6000 series & Scott AV-3000 |

| Contaminant Protection | Lead, asbestos, cadmium, arsenic, MDA, silica, welding fumes, mold spores, radioactive particulates |

| Protection Levels (OSHA PEL) | Up to 10× PEL (half-face), up to 50× with quantitatively fit-tested full facepiece |

| Physical Properties | Flame-resistant, water-resistant, abrasion-resistant; flexible polypropylene housing |

| Dimensions (per filter) | Approx. 4.3″ height × 4.3″ width (~11 cm × 11 cm) |

| Service Life | Discard if breathing resistance increases, or after 40 hrs of oil aerosol use / 30 days, whichever is first |

| Certification | NIOSH-approved P100; OSHA-compliant under 29 CFR 1910.134 |

| Pack Contents | 50 pairs (100 filters) |

| Color Code | Magenta (standard for P100 filters) |

How to Use / Installation Guide

1. Start with the right respirator

Ensure you’ve got a compatible 3M half- or full-face respirator, typically the 6000, 6500, 7500, 7800S, FF-400, or Scott AV-3000. If you’re using a 5000-Series, you’ll need the 502 adapter. Fit checks are essential, no facial hair or gaps permitted, OSHA requires a proper seal for safety.

2. Inspect filters before use

Each filter in the 50-pair pack is brand-new. Before attaching, lightly press the housing to ensure it’s intact and free of damage or obstructions. If damaged or deformed, throw it out.

3. Attach the filters

Align the magenta bayonet fitting on the filter with the respirator port (quarter-turn connection), then twist until it locks with a firm click. You should hear or feel it snap into place.

4. Seal check before entering hazardous area

On the assembled respirator, perform a positive and negative pressure check:

- Positive pressure: Cover the exhalation valve; exhale gentlym facepiece should slightly inflate without leaking.

- Negative pressure: Cover the inlet(s) with your palms; inhale gently, facepiece should collapse slightly and stay collapsed for at least 10 seconds .

No leakage, no surprises, you’re good to go.

5. Monitor usage carefully

As a P100-rated filter, it blocks ≥ 99.97% of particles, including oil-based and non-oil contaminants. But pay attention:

- Replace immediately if breathing becomes noticeably harder or if the filter gets visibly soiled or wet.

- If exposed only to oil aerosols, discard after 40 hours of total use or 30 days, whichever comes first.

6. Removing: do it smartly

When you need to remove or change filters, do it away from contaminated zones. With gloved hands, twist filters off in the reverse quarter-turn. Seal them in a bag and dispose, never inhale near the contaminated plumes while removing.

7. Maintain your respirator

Filters are single-use, do not wash or reuse them. Clean the facepiece per 3M instructions (soap and water work fine), let it fully dry, then store it in a clean, sealed container.

8. Storing unused filters

Keep the unopened filters dry and sealed. They’re rated up to 30 days once first exposed; after that, even unused filters begin to degrade.

Pro tip: Keep track of the first use date, mark it on the package. That way you’ll know exactly when your 30-day window closes.

Frequently Asked Questions

1. How long do these filters really last? Can I reuse them?

Yes, but with caution. These filters don’t have a hard “expiration” date once opened. Many users report safely reusing them until breathing becomes noticeably difficult or the surface looks dusty or wet. After about 40 hours of cumulative use in oily environments or 30 days after first use, 3M recommends discarding them, even unused, to maintain effectiveness.

Pro Tip: Mark the first-use date right on the bag with a permanent marker; that way, you’ll always know when that 30-day clock starts.

2. Can I wear these for mold, lead paint, and asbestos work?

Absolutely. The P100 rating means they capture 99.97% of airborne particles ≥ 0.3 µm, which includes microscopic asbestos fibers, lead dust, mold spores, and even heavy metal fumes like cadmium and arsenic. They’re designed for tough environments, from construction sites to industrial cleanups, so they’re perfect for that job list.

3. Do these filters work with all 3M respirators?

They work perfectly with most 3M half- and full-face respirators (6000, 6500, 7500, 7800S, FF-400) and with the 3M Scott AV-3000 family. If you’re using the older 5000-Series respirators, you’ll just need the right adapter (502 series). The magenta bayonet makes installing quick and universal.

4. Will breathing through these feel like sucking through a straw?

Thankfully, no. These filters are built with Advanced Electret Media (AEM), a charged, lightweight layer that grabs particles without needing extra energy to breathe through. Compared to older heavy filters, users often say breathing feels noticeably easier, even during hours of continuous use.

5. Are these safe around oil-based sprays or solvents?

Yes, they’re oil-proof (the “O” in P100), so they work in oil mist environments like welding fumes, metal pouring, or chemical spray booths. 3M officially states these filters are for use with both oil and non-oil particulates.

6. What should I do if I smell odors or taste chemical fumes?

These filters do not protect against gases or vapors, they’re particulate filters only. If you start noticing odors or a chemical taste, it means vapors are getting through. At that point, you need a combined cartridge that protects against vapors, or consider switching to a full-face respirator with the appropriate gas/vapor cartridges. And, it’s time to leave the area and reassess air quality.

7. How do I store unused filters properly?

Store them in a cool, dry place inside the sealed bag or container. Even unused filters start losing electrostatic efficiency after about 30 days of exposure to air or moisture. That’s why I recommend sealing them tight after first use—and using them up within a month.

Conclusion

You’ve walked through everything, from how these filters work, to real-life stories of relief in dusty, hazardous zones, to step-by-step guidance and FAQs filled with honest tips. The 3M P100 Respirator Filter 2091 isn’t just another accessory, it’s a dependable line of defense when risky particles threaten your health and peace of mind.

Picture yourself finishing that attic cleanup, renovation, or industrial job knowing every inhale is safer. These filters help you control your environment so you can focus on the task, not on coughing or worrying.

Trust the 2091 to:

- Filter out 99.97% of airborne hazards like asbestos, lead, arsenic, cadmium, mold, and silica.

- Stand up to tough conditions; flame‑resistant, water‑resistant, bayonet‑tough

- Pair with your existing respirator lineup; no adapter, no hassle

Related products

-

Sale!

50‑Pack 5N11 N95 Particulate Filter & 6001 Vapor Cartridge Kit

$19.99Original price was: $19.99.$18.99Current price is: $18.99. Buy Now -

Klein Tools 60553 P100 Half‑Mask Respirator S/M

$36.47 Buy Now -

12‑Piece 6001 Respirator Filter Cartridge Set with 5N11 Prefilters

$12.99 Buy Now -

Sale!

3M Rugged Comfort Half Facepiece Reusable Respirator 6503

$32.58Original price was: $32.58.$26.48Current price is: $26.48. Buy Now

Reviews

There are no reviews yet.