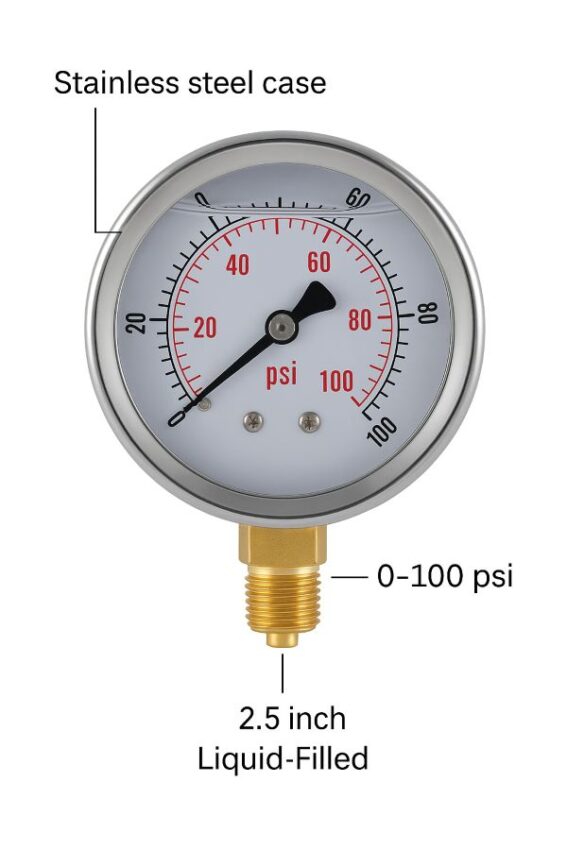

0 to 100 psi Liquid Filled Pressure Gauge, 2.5 in Dial, 1/4 in NPT Lower Mount

$12.25

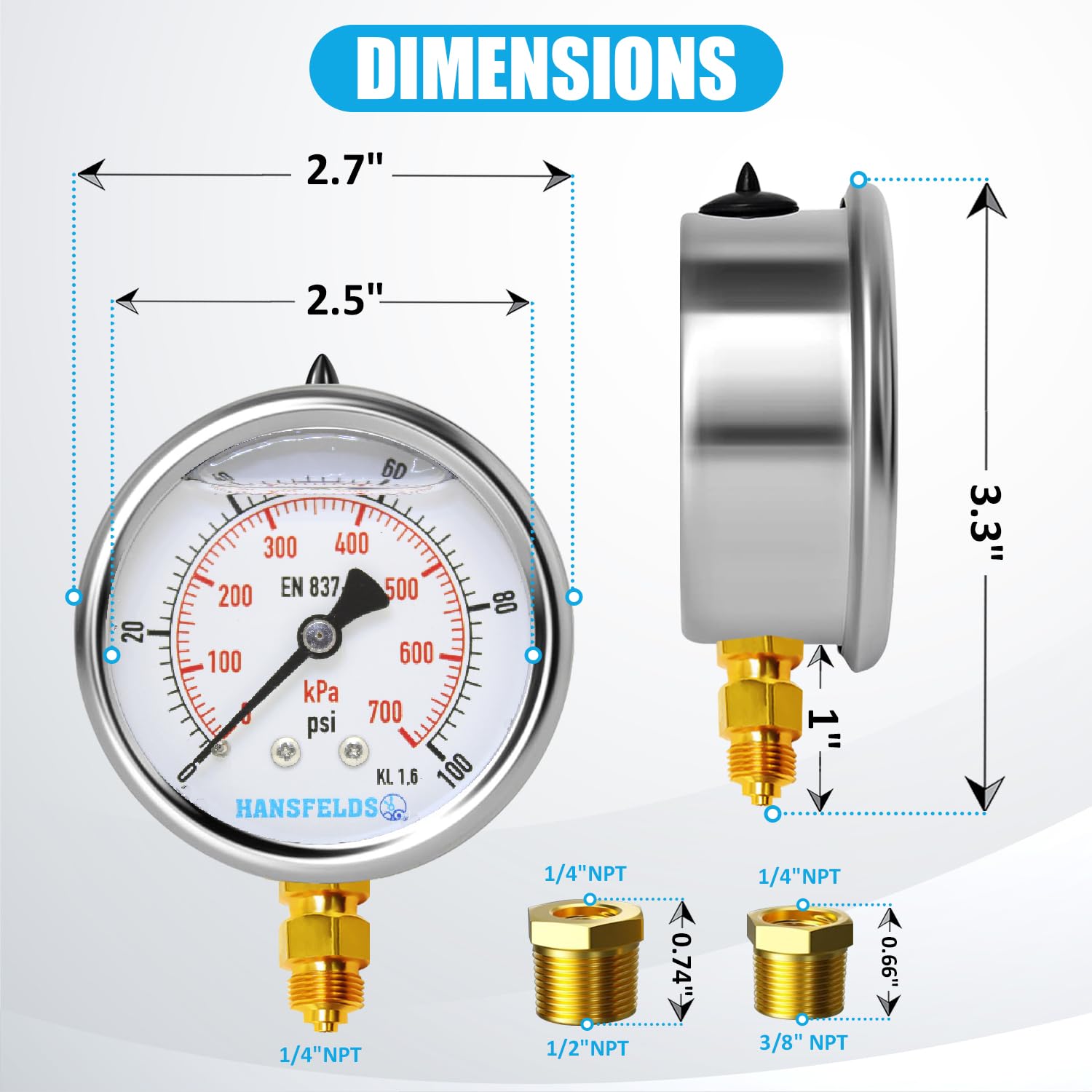

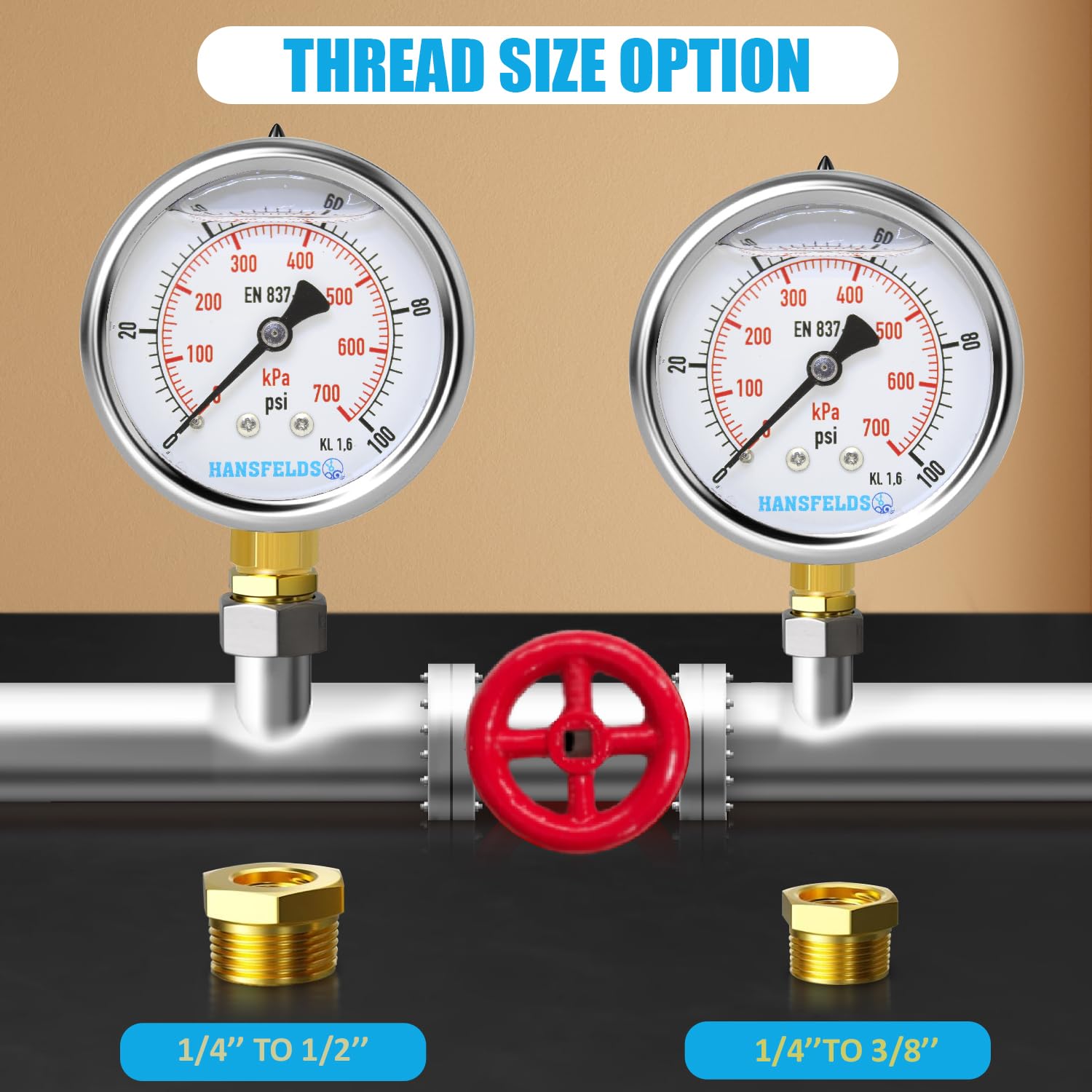

Get steady, easy-to-read pressure at a glance with this 0 to 100 psi liquid filled pressure gauge, 2.5 inch dial, 1/4 inch NPT lower mount, stainless steel case. The liquid fill cushions vibration so the pointer stays calm beside pumps, compressors, and outdoor lines, which protects the movement and helps the gauge last longer. Accuracy class one point six means the permissible error is one point six percent of the dial span, so on this range you are looking at roughly one point six psi. The bundle includes 1/4 inch to 3/8 inch and 1/4 inch to 1/2 inch NPT hex reducers, so you can drop it into common ports without a parts run.

Description

If your pump surges or a compressor chatters, a calm, readable needle is the difference between guessing and knowing. The 0 to 100 psi Liquid Filled Pressure Gauge, 2.5 in Dial, 1/4 in NPT Lower Mount, arrives ready for real-world duty, since the liquid fill damps vibration so readings stay steady and the movement lasts longer.

It also plays nicely with common ports in the field, thanks to the included 1/4 in x 1/2 in NPT and 1/4 in x 3/8 in NPT hex reducers, which let a 1/4 inch NPT gauge mount into larger NPT tappings without a scramble for extra fittings. And because accuracy class “1.6” refers to an error band based on percent of span, you have a clear sense of what the gauge can reliably show across the 0 to 100 psi range.

Key Customer Benefits

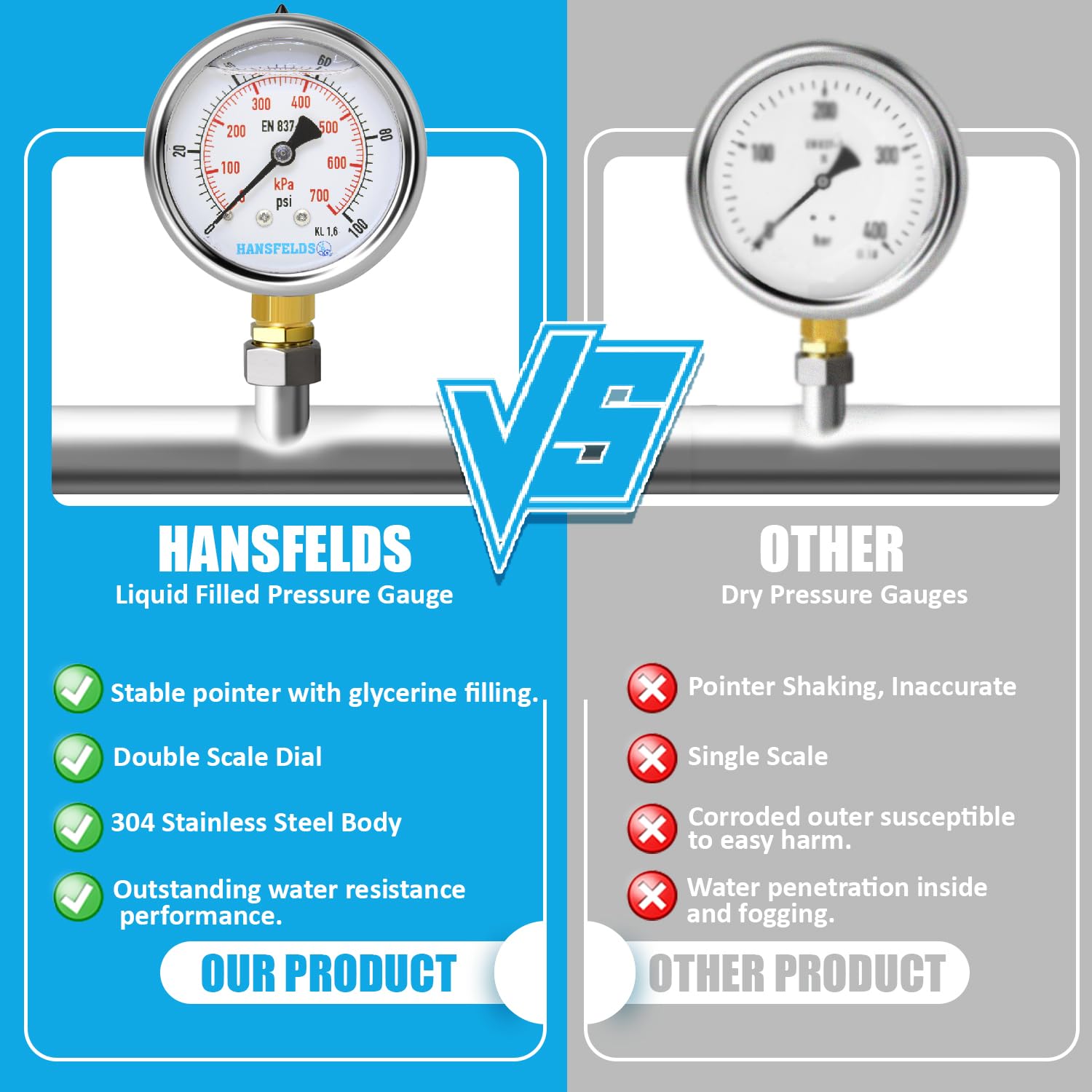

- Steady needle you can actually read: The liquid fill cushions the movement, so vibration and pump pulsation do not make the pointer flutter. You get a calm reading that is easier to see and trust, especially beside motors, compressors, or irrigation pumps. This damping effect also reduces wear on the mechanism, which helps the gauge last longer in tough service.

- Built to handle weather and messy jobs: A stainless steel case protects the internals from corrosion and harsh environments, while the liquid fill shields against temperature swings and moisture that can fog a dry gauge. That combination is a proven recipe for durability on water, oil, and general gas lines.

- Accuracy you can quantify, not guess: The dial is marked “Accuracy Class 1.6,” which means the permissible error is one point six percent of the full span. On a zero to one hundred psi scale, that translates to about one point six psi. Knowing the error band helps you decide if the reading is tight enough for your application, like setting pump cut-in and cut-out or tuning a regulator.

- Works across common temperatures, with fill options to match your climate: Glycerin fills perform well in typical shop and plant temperatures, while silicone fills stay mobile in colder conditions and at higher heat. Choosing the right fill for your weather means the needle stays smooth and responsive instead of sluggish.

- Fits the port you have today, not the one you wish you had: The included 1/4 in to 1/2 in NPT and 1/4 in to 3/8 in NPT hex reducers make it easy to mount a 1/4 in NPT gauge into larger NPT tappings without an extra supply run. NPT is the American National Standard taper pipe thread defined by ASME B1.20.1, so you can match threads and pitch confidently.

- Good process control for the price: Compared with dry gauges, liquid-filled designs are easier to read under vibration and often deliver longer service before failure. Fewer replacements and less unplanned downtime can lower your true cost of ownership over time.

Product Description

What this gauge is

This is a 0 to 100 psi liquid filled pressure gauge with a 2.5 inch dial, a 1/4 inch NPT lower mount, and a stainless steel case designed for water, oil, and general gas service. The movement lives inside a bath of fill liquid, typically glycerin or silicone, which stabilizes the pointer and protects the mechanism in places where motors hum, pumps pulse, or weather shifts quickly.

The accuracy class 1.6 marking tells you its permissible error band is one point six percent of the full span, which on a zero to one hundred psi dial means about one point six psi. That clarity helps you choose a gauge that truly fits the job.

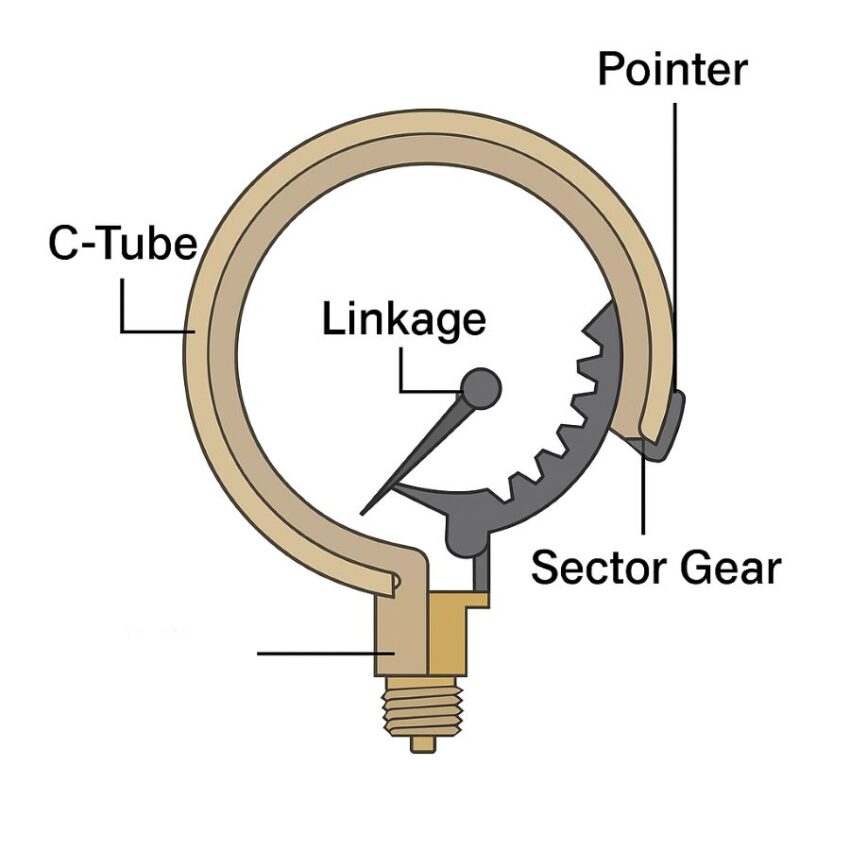

How it works under the hood

Inside is a Bourdon tube that flexes slightly when pressure rises. That tiny flex is transmitted through a geared movement to the pointer you see. Bourdon tube gauges are popular in plants and shops because they are reliable, inherently mechanical, and do not need power. The stainless case keeps the mechanism aligned and clean, while the liquid fill lubricates moving parts and damps vibration so the needle stays readable instead of jittering.

Why liquid filling makes a practical difference

Compared with dry gauges, liquid filled models handle vibration, shocks, and pressure pulsation better, which reduces wear and extends life. Glycerin is the common fill and performs well near room temperature. Silicone stays more stable when it is cold or hot, so the pointer does not go sluggish in winter or under hood heat. The goal is simple, a smooth pointer that you can read at a glance.

Designed for real installations

The 1/4 inch NPT male process connection is the standard tapered pipe thread used widely in North America, defined by ASME B1.20.1, so it mates cleanly with common valves and tees.

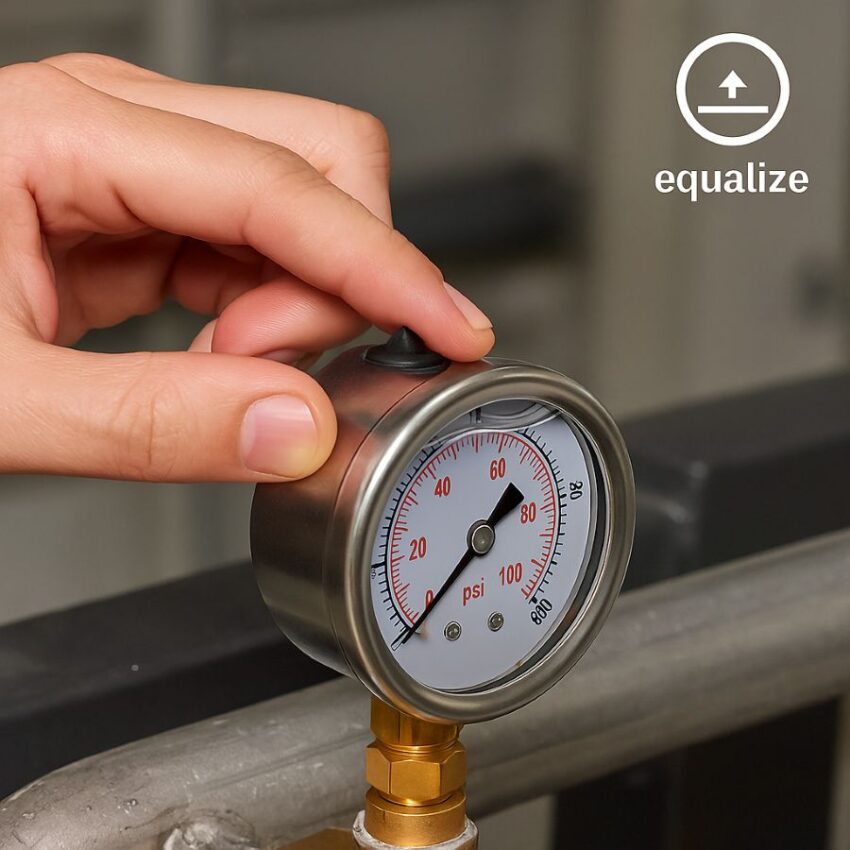

This bundle also includes 1/4 in x 1/2 in NPT and 1/4 in x 3/8 in NPT hex reducers, which means you can land a quarter-inch gauge into larger existing taps without a last-minute parts run. If your site is at altitude or sees big temperature swings, modern liquid filled gauges include a small vent or compensating plug. Opening it equalizes the case with ambient air, which improves pointer behavior and prevents the clear window from bowing.

What makes this build effective and different

A stainless steel case resists corrosion and weather, which is essential around washdowns, splash, and outdoor manifolds. The class 1.6 accuracy gives you predictable performance across the scale, not a vague promise. In practice, on a pump set to cut out at 60 psi, you can expect the reading to be within roughly one and a half psi when the gauge is healthy and properly installed. Those are the kind of numbers techs rely on when setting regulators or verifying irrigation pressure.

Product Specifications

| Category | Spec |

|---|---|

| Pressure range | 0 to 100 psi |

| Dial size | 2.5 inch nominal (63 mm) |

| Accuracy class | Class 1.6 per ASME B40.100 and EN 837-1 |

| Case material | Stainless steel, typically 304 |

| Window | Clear plastic or glass, model dependent |

| Movement and measuring element | Bourdon tube with geared movement |

| Wetted parts | Typically copper alloy on utility stainless-case gauges |

| Process connection | 1/4 inch NPT male, lower mount |

| Adapters included | 1/4 in NPT to 1/2 in NPT hex reducer and 1/4 in NPT to 3/8 in NPT hex reducer |

| Fill liquid | Glycerin by default, silicone optional |

| Operating temperature, typical | With glycerin fill, approx. -5°C to +65°C; with silicone fill, approx. -40°C to +65°C |

| Accuracy shift with temperature | About 0.4 percent of span for each 14°C away from 20°C reference |

| Ingress protection, typical for this style | Around IP65 on stainless-case, crimped-ring designs |

| Overload capability, typical Bourdon tube | Short-term about 1.3 times full scale |

| Safety features | Blow-out back or relief on many models |

| Vent or compensation | Vent plug or lever on many liquid-filled models |

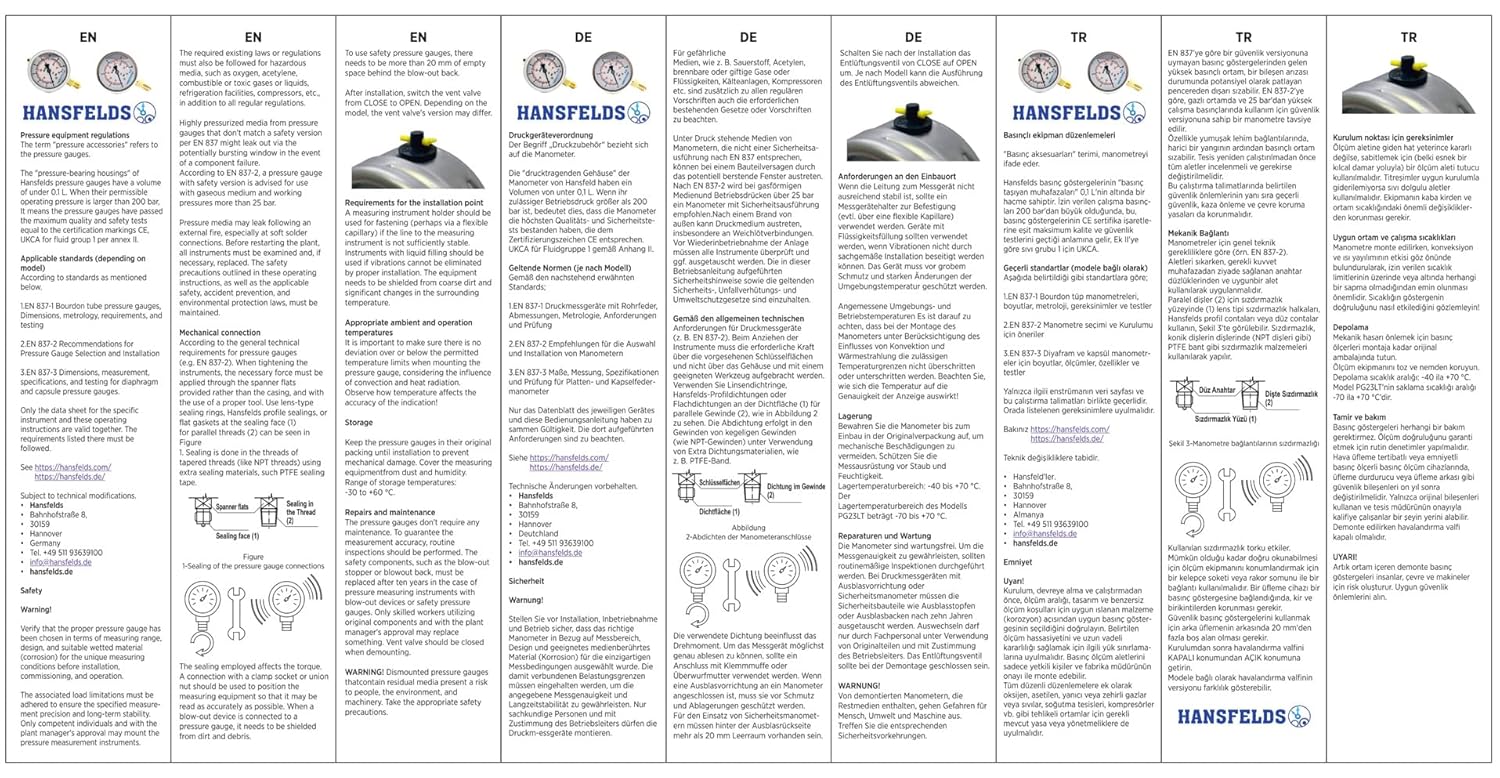

| Compliance references | ASME B40.100 for accuracy, EN 837-1 for construction, ASME B1.20.1 for NPT threads |

How to Use and Install the Gauge

Before you start: pick the right range and protect the gauge

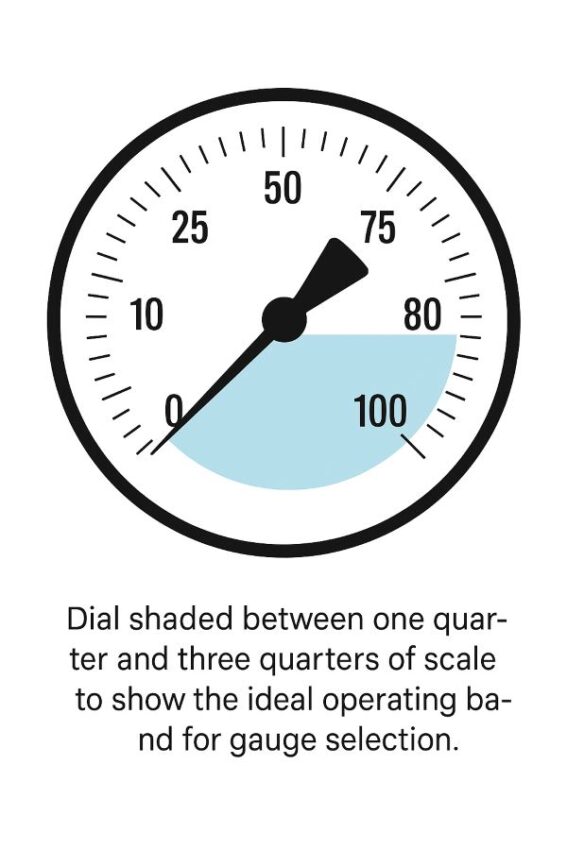

For everyday water, oil, or air lines, choose a span where your normal operating pressure sits between one quarter and three quarters of the dial. On a zero to one hundred psi gauge, that means most of your readings should live roughly between 25 and 75 psi. This follows ASME B40.100 practice, which helps your pointer live in its most accurate and least stressed zone. If you expect fast pressure spikes, choose the next higher range and add a pulsation device such as a snubber or micro needle valve to calm the movement.

If the line is steam, you must keep heat away from the Bourdon tube. Install a pigtail siphon or cooling element and a small shutoff valve so condensate forms a protective water seal and you can isolate the gauge for service. This prevents early failure from continuous high temperature.

What you need on the bench

- The 0 to 100 psi liquid filled pressure gauge with 1/4 inch NPT lower mount.

- The included 1/4 inch to 1/2 inch NPT or 1/4 inch to 3/8 inch NPT hex reducer, if your port is larger.

- A quality thread sealant, either PTFE tape or a compatible pipe dope. Use only enough to seal, and keep the first thread clean to avoid debris in the line.

- If the system has pulsation, a snubber or a small needle valve to slow the pressure wave is recommended.

Step 1: depressurize and verify compatibility

Shut the valve feeding the tap, bleed the port to zero pressure, and verify that the wetted parts and case rating match your media and environment. Check for temperature, vibration, and pulsation before installing.

Step 2: prep the threads the right way

For tapered NPT threads, do not chase a torque number. Use engagement by turns, which means you start hand tight and then go one to two wrench turns to seal, taking care not to overdo it. Overtightening distorts the taper and can crack female fittings, especially with reducers. Keep sealant off the first thread to avoid shedding into the process.

Step 3: install with a wrench on the fitting, not the case

Thread the reducer into the port if you need it, then install the gauge. Always place your wrench on the hex of the gauge fitting or reducer, never on the case or window. Tighten to achieve proper engagement and orientation so you can read the dial square on. This protects the movement from twisting and preserves alignment.

Step 4: add pulsation protection if the needle vibrates

If the application has pump ripple or compressor chatter, fit a porous snubber or an adjustable micro needle valve ahead of the gauge. These devices act like shock absorbers, smoothing the pressure wave so the liquid filled movement can do its job.

Step 5: power up, then vent the case after warm-up

Liquid filled gauges are shipped sealed. As the case warms in service, trapped air expands and can nudge the zero off slightly or cause the window to bow. Open the vent plug or lever on the back after the gauge reaches operating temperature, then re-close if the design requires it. This equalizes the case with atmosphere and stabilizes the pointer.

Step 6: check zero, leak test, and mark your setpoints

With the process still at zero pressure, confirm the pointer sits at zero. If the case has a zero adjustment, make a small correction following the manual. Bring the line up slowly, soap-test the joint for leaks, and mark your typical setpoints on the bezel or in your maintenance notes. Keep in mind that class 1.6 means the allowable error is about one point six psi on this one hundred psi dial, which is appropriate for utility service.

Step 7: mind the temperature and fill choice over the seasons

Glycerin filled gauges read smoothly in ordinary plant and field temperatures, while silicone fill stays more fluid in cold mornings and remains stable at heat. A glycerin and water blend can extend cold performance without freezing. Choose the fill that matches your climate so the pointer does not become sluggish.

Step 8: operate within limits and service on a schedule

A sound rule is to keep normal operation between one quarter and three quarters of scale, avoid steady operation near the top of the range, and never exceed the upper range limit. In high-pulsation services, running the gauge near the lower end of its dial and using a snubber reduces wear. Add a small isolation valve below the gauge so you can remove it for inspection and recalibration without draining the whole line.

Common Issues and Solutions

- Pointer off zero after install: warm the gauge in service, open the vent, then recheck. Case pressure was likely trapped.

- Pointer chatter: fit a snubber or needle valve and verify the fill type suits your temperature.

- Slow response in cold: consider silicone fill for better low-temperature mobility.

Frequently Asked Questions

Why does my liquid filled gauge not return to zero after installation?

Two things often shift the pointer slightly off zero. First, liquid filled gauges are sealed, so temperature changes during shipping or start-up can expand the fill fluid and build case pressure, which nudges the pointer. Second, elevation changes between factory and site can do the same. The fix is simple. Once the system warms to operating temperature, open the small vent on the gauge to equalize the case with ambient air. Venting restores zero and improves accuracy in service.

Glycerin or silicone fill, which should I choose?

Both damp vibration and protect the movement, but they behave differently with temperature. Glycerin is very effective at damping in typical plant conditions. For cold starts or broader temperature swings, silicone stays more mobile, so the pointer remains responsive. A practical rule is to use glycerin for ordinary room to warm conditions, and silicone when mornings are very cold or the installation sees heat.

What does accuracy class 1.6 really mean on a 0 to 100 psi dial?

Accuracy class 1.6 means the permissible error is one point six percent of the full span. On a zero to one hundred psi gauge, the allowable error band is about one point six psi across the scale. Accuracy is defined as a percent of full scale, not of the indicated value. That is why picking a range that centers your normal readings helps you see meaningful changes.

My pump makes the needle chatter. Do I need a snubber if the gauge is already liquid filled?

Yes, often you do. The fill calms the pointer, but strong pulsation from reciprocating pumps or compressors still reaches the Bourdon tube. A snubber or adjustable micro needle before the gauge absorbs sudden pressure swings, which stabilizes readings and extends instrument life.

Can I screw a pressure gauge directly into a steam line?

Not directly. Even low pressure steam can exceed a gauge’s temperature rating. Install a pigtail or coil siphon and a small isolation valve. The siphon traps condensate that keeps heat away from the gauge, which protects the movement from continuous high temperature.

How do temperature and fill type affect the usable temperature range?

The usable ambient range depends on whether the gauge is dry or liquid filled and on the type of fill. Glycerin, silicone, and other fills each have different min and max limits. As temperature moves away from the calibration reference, expect small accuracy shifts. Choosing a fill that matches your climate keeps the pointer responsive and the reading credible.

Do liquid filled gauges really last longer in vibration?

They are designed for exactly that problem. The case liquid acts as a cushion that stabilizes the pointer in pulsation and vibration and reduces the impact of sudden spikes on the mechanism. This improves readability and can reduce wear over time. If vibration is extreme, consider a snubber plus case fill, or alternative damping solutions.

How should I install the gauge threads, and is there a torque spec?

For tapered NPT threads there is usually no fixed torque value because sealing relies on thread interference. Apply a compatible sealant sparingly, start the gauge hand tight, then tighten by wrench until leak-free orientation is achieved. Always wrench on the fitting or adapter hex, not on the case.

When should I vent a liquid filled gauge?

Venting is recommended after installation and warm-up, and anytime you notice the window bowing outward or the pointer not returning to zero at rest. This equalizes case pressure with local atmosphere so the pointer tracks correctly.

I saw people on forums say silicone is better in the cold. Is that true?

Yes. Silicone filled gauges remain lively in cold weather where glycerin can thicken. Use that as a practical tip and confirm against the maker’s temperature tables for your exact model.

Do standards differ between ASME and EN for accuracy classes?

Yes. Both frameworks express accuracy as a percent of span, but the class labels and tables differ. ASME B40.100 and EN 837-1 define classes and test methods separately. When you read “Class 1.6,” treat it as a percent of the full scale, then check the manufacturer datasheet for the exact standard referenced.

Conclusion

When you need a calm, readable pointer on a noisy line, a 0 to 100 psi Liquid Filled Pressure Gauge, 2.5 in Dial, 1/4 in NPT Lower Mount is exactly the kind of tool that earns its keep. The liquid fill cushions the movement so vibration does not turn the dial into a blur, which protects the mechanism and makes the number you read feel trustworthy.

Small operational habits keep it honest. Vent the case after installation and warm-up so the inside of the gauge is at the same pressure as the room, then your zero and mid-scale readings will stay true. If your pump or compressor is a bit rowdy, add a snubber or a tiny needle valve to smooth pulsation before it reaches the Bourdon tube. These two steps are simple and well supported by manufacturer guidance.

Choose the right range so most of your day-to-day readings sit roughly between one quarter and three quarters of the dial. That selection aligns with established practice and preserves accuracy where you actually operate. Remember what “accuracy class 1.6” means in real life. The allowed error is one point six percent of the full scale, so on a zero to one hundred psi dial you are looking at roughly one point six psi. That is a practical level for water systems, shop air, irrigation, and many oil or gas utilities.

Reviews

There are no reviews yet.