Backpack Sprayer Seal Gasket Kit 182656: Viton Pump Service Kit

$16.99

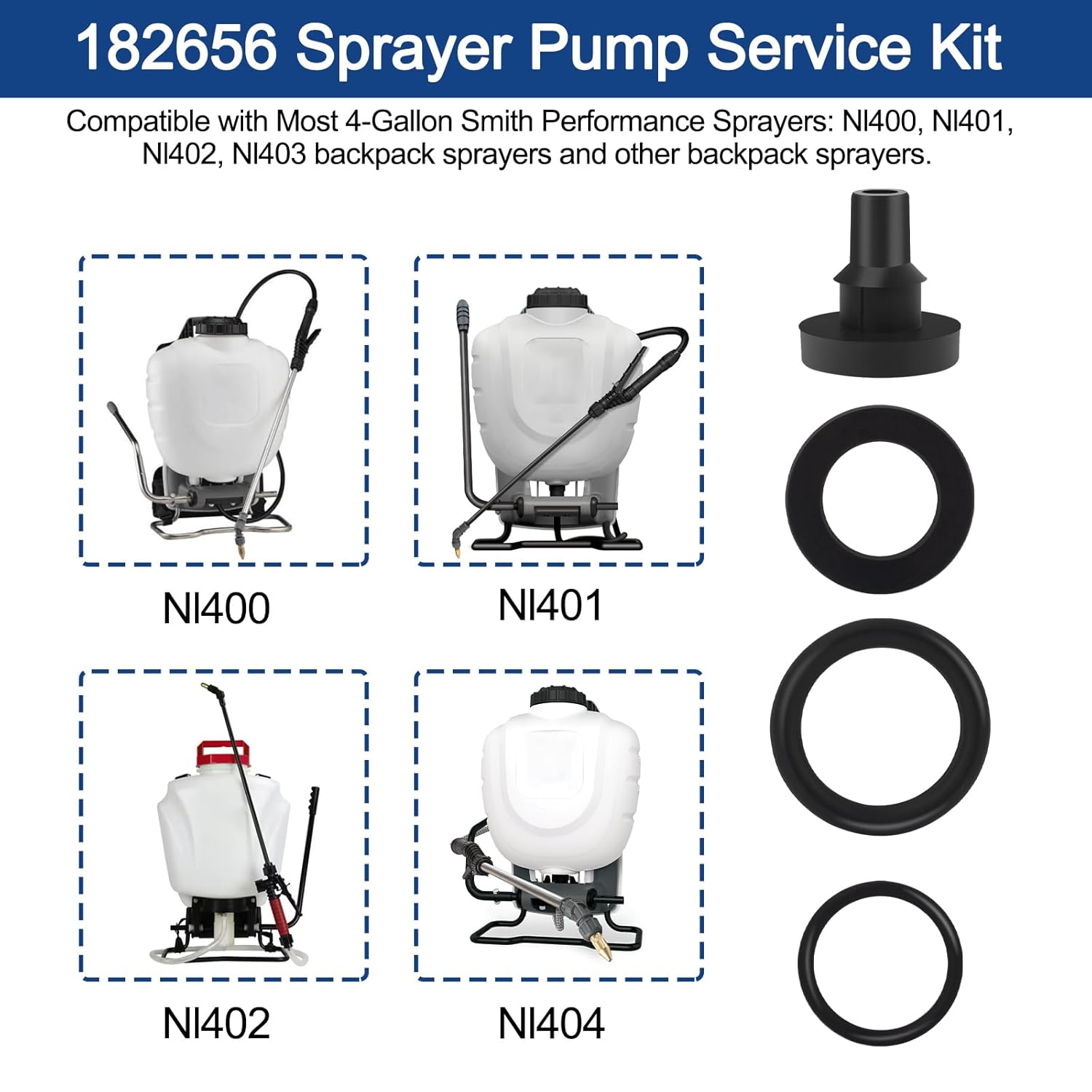

Refresh your Smith backpack sprayer the right way with the Backpack Sprayer Seal Gasket Kit 182656. This factory Viton pump service kit is made for NL400, NL401, NL402, and NL403 four gallon No Leak models, so fit and performance are on spec. It includes the core wear parts you replace first to stop leaks and restore prime. You get a pump gasket, a tank grommet, and two Viton O-rings that reseal the internal pump for a clean, even pattern. Viton is chosen for strong chemical resistance, which helps seals last through real world mixes. With healthy seals, the NL400 platform’s internal piston pump can again deliver up to 150 psi as designed.

Description

When a backpack sprayer starts to lose pressure or dribble at the shut-off, it is almost always tired seals talking. The Backpack Sprayer Seal Gasket Kit 182656 is the factory-specified Viton pump service kit for Smith Performance Sprayers NL400, NL401, NL402, and NL403 four-gallon no-leak backpacks. It is purpose-built to refresh the heart of the pump and bring your spray pattern back to a crisp, reliable fan.

Inside the 182656 kit you get the exact wear parts pros replace first: a pump gasket, a grommet, and two Viton O-rings, so you can stop air leaks, restore prime, and get back to even coverage without buying a new sprayer. Viton is chosen here for a reason. It is a fluoroelastomer known for strong resistance to many herbicides, pesticides, and solvents commonly used in pest management and turf care, which helps the repair last longer under real jobsite chemistry.

As a pest control tech, I value how these Smith no-leak backpacks are designed around maintainability. The NL400 family runs an internal pump architecture rated up to 150 PSI with Viton seals throughout the pump and shut-off, which means the right seal kit can truly make the unit feel new again after a season of work. If your trigger is weeping or you need extra strokes to build pressure, this is the small, inexpensive fix that solves a big headache.

Key Customer Benefits

- Stops pressure loss and restores a clean spray pattern. If your NL400-series backpack needs extra strokes to build pressure, or the trigger is weeping, worn pump seals are the usual culprit. Refreshing the pump gasket, grommet, and Viton O-rings in the Backpack Sprayer Seal Gasket Kit 182656 brings back fast priming and an even fan, instead of sputters and drips. Techs on lawn and turf forums commonly trace “air in the line” and tip spitting to leaks ahead of the pump, which a seal kit fixes at the source.

- Built for the NL400 family, so fit is right the first time. This is the Smith Performance Sprayers factory-specified Viton pump service kit for the NL400, NL401, NL402, and NL403 no-leak four-gallon backpacks. That means dimensions, durometers, and profiles match the original parts, so you do not have to fight with near-fits or trim generic rubber.

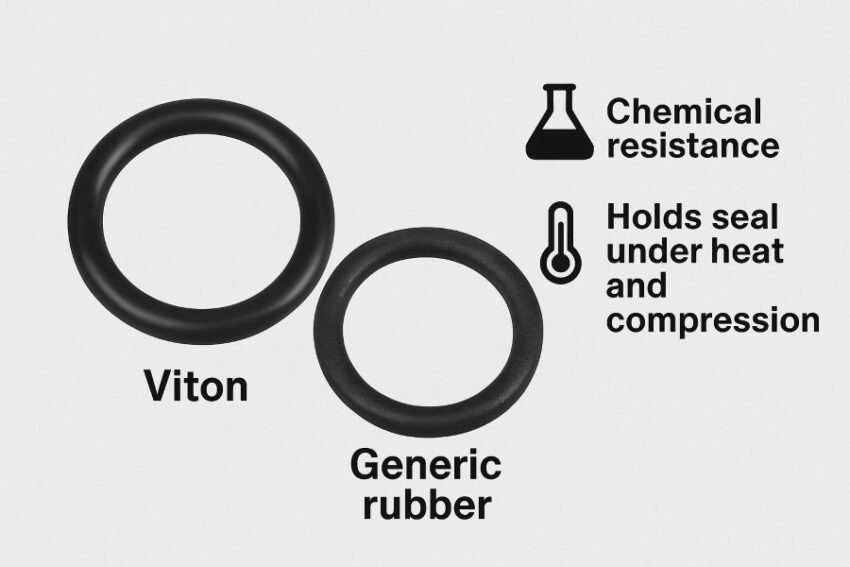

- Chemical-resistant Viton parts hold up to real jobsite chemistry. Viton fluoroelastomer is chosen for durability with many pesticides, herbicides, oils, and solvents used in pest control and turf work, and it maintains sealing under heat and compression better than typical non-fluorinated rubbers. That gives you longer service intervals and fewer mid-season rebuilds.

- Quick, clean swap you can do between stops. The kit is designed for easy replacement, so most pros can pull the pump, swap the gasket, grommet, and O-rings, and be spraying again in short order with no special tools. If you rely on steady output up to the sprayer’s rated pressure, a tight seal set helps the NL400 platform deliver.

- Protects your investment and reduces chemical waste. Drips, misting, and rework cost time and product. Replacing tired seals minimizes leaks at the shut-off and pump, which keeps application rates predictable and prevents over-application that can scorch turf or stain surfaces. Compatibility charts for Viton reinforce why these seals are a smart choice when you run a mixed roster of products across a season.

- Peace of mind for techs and homeowners alike. When a sprayer behaves like new, jobs go smoother. The 182656 kit is a small, low-cost fix that restores confidence in your no leak backpack sprayer parts. If you have been hunting for a Viton O-ring replacement for Smith NL400 or a dependable pump service kit for a garden sprayer, this checks all three boxes with parts matched to the platform.

Product Description

What This Kit Is

The Backpack Sprayer Seal Gasket Kit 182656 is the factory Viton pump service kit specified for Smith Performance Sprayers NL400, NL401, NL402, and NL403 four-gallon no-leak backpacks. It is the small set of wear parts that restores the pump’s seal so your sprayer primes quickly and holds pressure. The manufacturer confirms compatibility with the entire NL400 series and labels it a Viton pump service kit for those models.

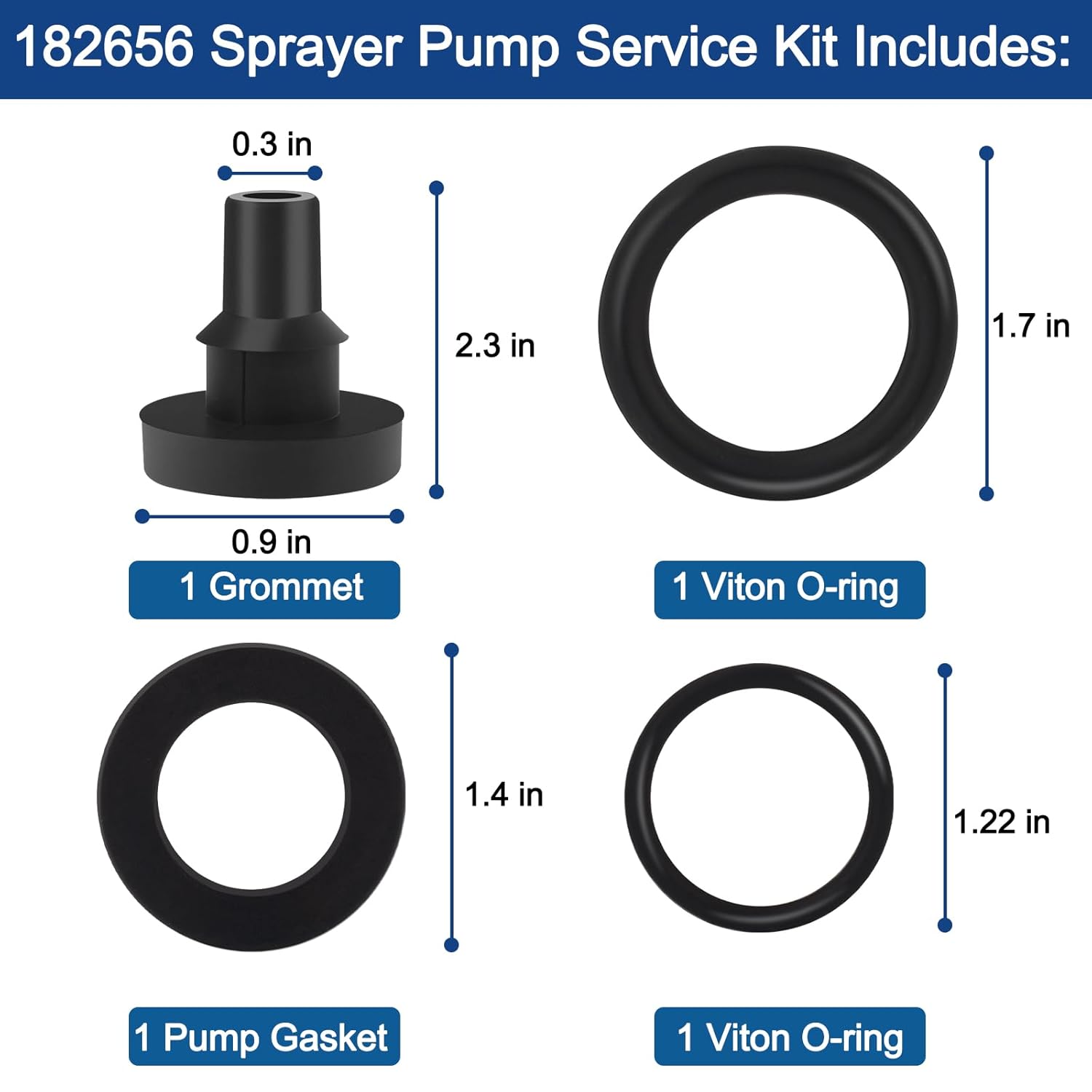

Inside the kit are the exact components that take a beating over a season of herbicides and insecticides. The NL400 series user manual lists the contents under Kit #32, part 182656 as: reservoir or chamber O-ring (32A), pump gasket (32B), tank grommet (32C), piston O-ring (32D), and a Viton check valve (32E). That is everything you need to reseal the wet side of the pump.

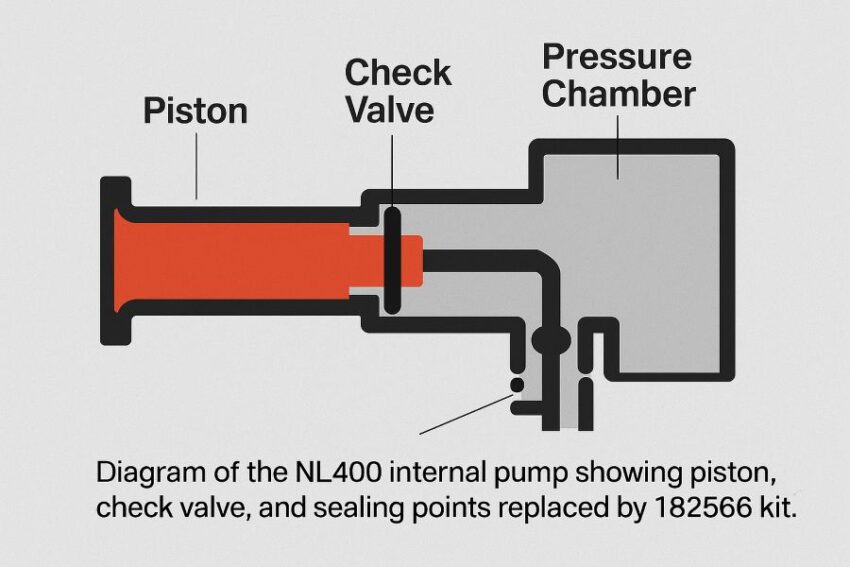

How It Works Inside the NL400 No-Leak System

The NL400 platform uses an internal piston pump housed inside the tank, which protects you from drips on your back and lets the unit build serious pressure, up to 150 PSI. Because the pump is internal and pushes against a pressure chamber, small seals do big jobs. If those seals harden or nick, air sneaks in, prime is lost, and you start pumping more often for less output. The official product page lays out these design points, including the internal pump, the 150 PSI rating, and the ability to spray both wettable powders and liquids.

When performance falls off, this kit refreshes each sealing interface. The piston O-ring (32D) restores the tight fit between piston and cylinder, the tank grommet (32C) seals the rod where it passes into the tank, the pump gasket (32B) reseals the pump to the tank body, the chamber O-ring (32A) keeps the pressure reservoir airtight, and the Viton check valve (32E) keeps flow one-way so the pump holds prime. The manual’s troubleshooting section even points to these parts by number when you see symptoms like “won’t build pressure,” leaks at the bottom of the tank, or stiffness in the handle.

Why It Is Effective and Different

Two things set this kit apart. First, it is engineered for the NL400 family. The dimensions and durometer match the originals, so you do not fight near-fits from generic rubber. Second, the sealing materials are Viton where it matters. Viton is an FKM fluoroelastomer widely chosen for pesticide and solvent resistance, and independent compatibility charts list strong performance across many common lawn and pest control chemistries. That gives you longer service intervals and fewer mid-season rebuilds compared with non-fluorinated rubbers.

The sprayer itself is built for quick service. Smith calls out easy to change seals on the NL400 product page, and the manual shows the step-by-step sequence for removing the pump, swapping the gasket and O-rings, and popping in a fresh grommet. No special tools are required for the core seal swap. For busy techs who care about uptime, those design decisions matter.

Usage Scenario

On a summer pest route, I watched a tech struggle with an NL402 that needed more strokes than usual to hold a clean fan. A faint damp ring had formed around the pump mount, and the handle felt sticky halfway through each stroke. Classic signs of a tired piston O-ring and tank grommet. We followed the manual: depressurized, pulled the pump, replaced the pump gasket, piston O-ring, and grommet from Kit 182656, then checked the chamber O-ring before reassembly. The sprayer built pressure in a handful of pumps and held steady through a full perimeter treatment. The troubleshooting section in the manual reads like a checklist for that exact scenario, linking poor pressure and bottom-of-tank leaks to the very seals included in the kit. It is a fifteen-minute fix that can save a day’s worth of callbacks.

What This Means For You

If your NL400-series backpack is spitting at the tip, leaking near the pump, or losing prime, you likely have air getting in before the pump. Replacing the sealed interfaces with the Backpack Sprayer Seal Gasket Kit 182656 restores the integrity of the internal pump, which returns the system to its design performance: clean pattern, steady pressure up to 150 PSI, and the ability to run powders and liquids without fuss. That is exactly how these no-leak sprayers were intended to work.

Product Specifications

| Spec | Details |

|---|---|

| Product name | Smith Performance Sprayers Viton Pump Service Kit, part 182656. |

| Compatible sprayers | NL400, NL401, NL402, NL403 four gallon No Leak backpacks. |

| What is in the kit | KIT #32 contents per manual: 32A Reservoir or chamber O-ring (171488V), 32B Pump gasket (171740), 32C Tank grommet (181668), 32D Piston O-ring (171487V), 32E Viton check valve (171015V). |

| Seal material | Viton FKM fluoroelastomer, chosen for chemical resistance with many pesticides, herbicides, fuels, and solvents. |

| Primary purpose | Restore airtight, liquid-tight seals in the NL400 internal pump so the sprayer primes quickly and maintains pressure. The kit targets the most common leak paths that cause pressure loss. |

| Sprayer pressure capability | Applies to the NL400 platform: internal piston pump rated up to 150 psi. Restoring seals helps the sprayer reach and hold its designed pressure. |

| Chemical compatibility guidance | Viton shows strong resistance across a wide set of chemicals. Always verify your specific active ingredient and carrier in a Viton compatibility chart and on the chemical label before use. |

| Typical tools for install | Clean water for testing, soft cloths, petroleum jelly for O-ring lubrication, hand tools. The manual explicitly calls for an adjustable wrench to remove and retighten the pump nut, and pliers to remove the tank grommet. |

| Estimated swap time | About one short service window for an experienced user, since the kit is focused on primary seals. Time varies by familiarity and cleaning steps. |

| Safety notes | Test with water before chemicals, wear eye protection and gloves, release pressure before servicing, never use flammable liquids, caustics, acids, or hot water in the tank. Follow label PPE. |

| Manufacturer support | The Fountainhead Group, customer service 1-800-311-9903, [email protected], as listed in the manual. |

| What this kit does not change | Flow rate and application coverage depend on your nozzle, tip, and pressure selection, not on the seal kit. The kit restores sealing, it does not alter the sprayer’s rated output hardware. |

How to Install and Use the 182656 Seal Gasket Kit

Before You Start: Safety and Setup

Park the sprayer on a clean bench, then put on gloves and eye protection. Always test and flush with clean water before you put any chemical back in the tank. Smith’s manuals emphasize a water test and PPE first, every time.

Release pressure the right way. Squeeze the shut-off and pump until the tank is empty, then keep squeezing without pumping until all air bleeds out. This prevents surprise sprays and makes the pump easier to remove. The NL403 service instructions list this depressurize-before-service sequence step by step.

Identify the Parts in Kit 182656

This is the Smith Performance Sprayers factory Viton pump service kit for NL400, NL401, NL402 and NL403 backpacks. It contains the primary seals you replace when pressure falls off or you see weeping at the pump interface. The manufacturer’s product page confirms model compatibility and “easy to change seals.”

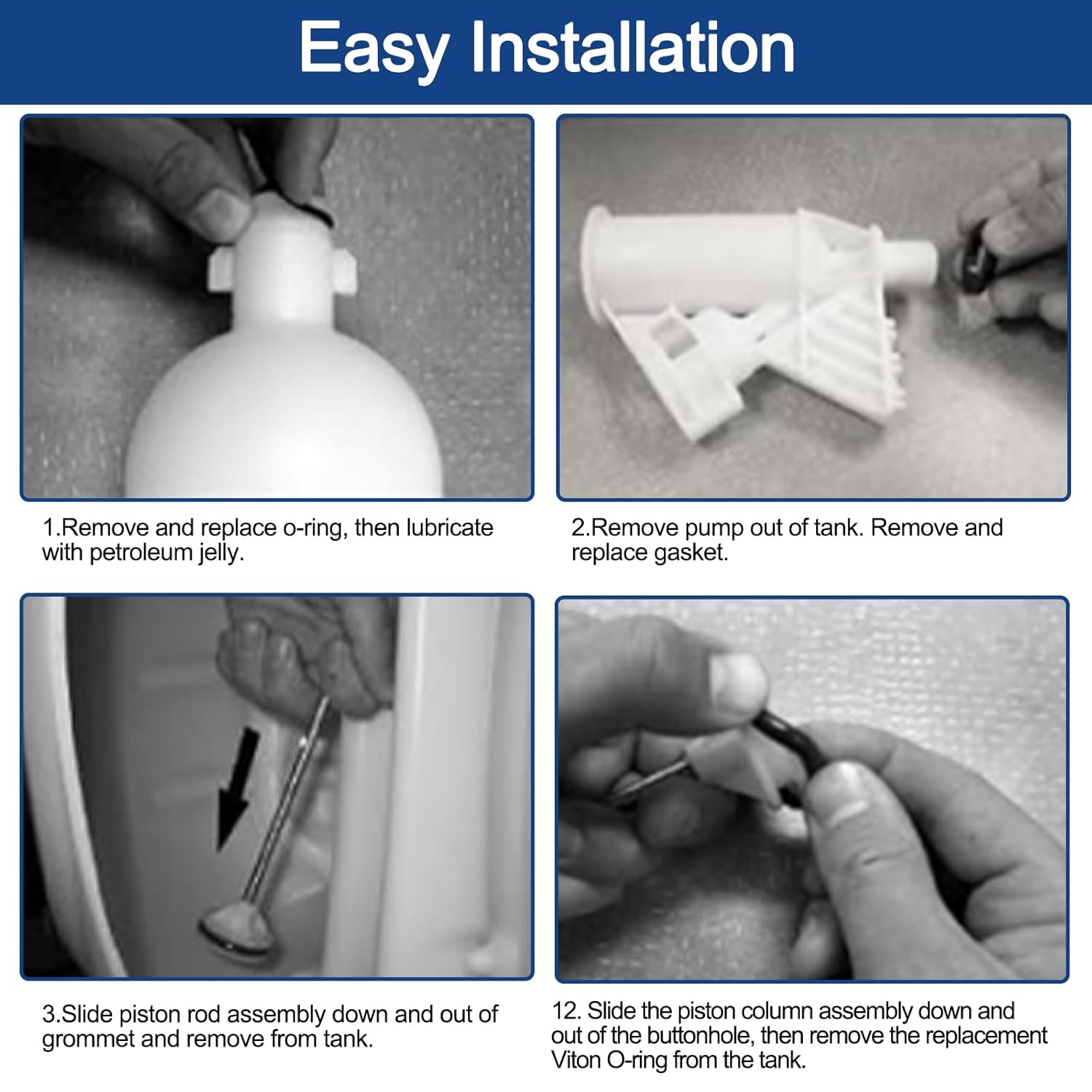

Disassembly: Getting to the Seals

- Remove the pump assembly. After depressurizing, loosen the carry handle screws if needed, then withdraw the piston rod.

- Unthread the pump nut. Hold the pump firmly and use an adjustable wrench to loosen the nut, then remove the nut, hose and barb assembly. These specific actions are called out in the Servicing Instructions for the NL400 family.

Watch the filter basket seal at the tank neck. If it is missing or warped, you can chase phantom leaks forever. The manual’s operating and maintenance sections remind you to verify the basket and gasket are in place before every use.

Replacing Each Seal: What Goes Where and Why It Matters

Pump gasket and tank grommet: The gasket seals the pump body to the tank. The grommet seals the rod where it enters the tank. If you see dampness around the pump mount or feel drips on your legs while pumping, these are usual suspects. Replace both, seat them evenly, and avoid twisting the grommet.

Piston O-ring and chamber O-ring: A tired piston O-ring causes hard strokes, poor prime, and sputtering. The chamber O-ring keeps the internal pressure reservoir airtight. Swap both with clean hands, then apply a light film of lubricant so the O-rings do not roll or nick during reassembly. Petroleum jelly is commonly specified for standard Smith models, while silicone grease is used for acetone sprayers. Keep the film very light.

Check valve: If the unit loses prime or spits at the tip, the wet-side check valve may be worn. Install the new Viton check valve from the kit with a firm press.

Reassembly and Torque Sense

Reinsert the piston rod, align the pivot clip and hitch pin, and snug the six handle screws evenly. Reconnect the hose and barb, then hand-start the pump nut before you put a wrench on it. A firm, even seal is your goal.

Prime, Pressure Test, and Pattern Check

Fill with two to three liters of clean water. Pump up and watch for leaks at the pump interface and grommet while you hold pressure. Then open the shut-off and observe the fan pattern for clean edges rather than sputters. If you cannot build pressure or you get air at the tip, you still have air sneaking in before the pump or you are cavitating the pump.

Remember, the NL400 platform is built to reach high working pressure. Restored seals help you achieve the sprayer’s rated performance and crisp pattern again.

Lubricants and Chemical Compatibility

Smith documentation for non-acetone units repeatedly references petroleum jelly as the routine O-ring lubricant, with silicone grease specified for acetone models. Use only a thin film, and never substitute random oils that can attack elastomers. When in doubt, pick a silicone-based O-ring grease rated for chemical service and verify the chemistry you run.

Common Mistakes That Cause Repeat Leaks

- Over-tightening hose barbs or the pump nut, which distorts soft seals and creates a slow leak under pressure.

- Skipping the filter basket gasket. If it is missing or worn, the tank neck will seep.

- Dry installing O-rings. A dry install rolls or nicks the seal, and you chase pressure problems all week.

Maintenance

Rinse the tank with cool, clean water after each job, inspect the check valve and filter basket, and store the unit depressurized. Plan to clean and lightly lube O-rings at least once per season, more often under heavy use.

If pressure still fades quickly, go back to the suction side. Make sure the suction tube is fully submerged and every connection between tank and pump is airtight. Leak before the pump or cavitation is the most common diagnosis from seasoned turf pros. If parts are damaged, Smith lists the service kit and support line in the manual, and the kit page offers documentation and troubleshooting links.

Frequently Asked Questions

Will the 182656 kit fit my sprayer?

Yes. The Backpack Sprayer Seal Gasket Kit 182656 is listed by the manufacturer for Smith Performance Sprayers NL400, NL401, NL402, and NL403 four gallon No Leak backpacks.

What parts are actually in the kit?

Retail product descriptions for the 182656 kit consistently show the essentials most users end up replacing first. Expect a pump gasket, a tank grommet, and two Viton O-rings. Those are the wear points that restore prime and stop seepage at the pump interface.

How do I know I need a seal kit and not a new shut-off or hose?

Look at symptoms. If the sprayer needs lots of pumping to hold pressure, spits at the tip, or you see dampness around the pump mount, the leak is usually before the pump and the seal kit is the fix. If the sprayer will not stop spraying or leaks at the trigger, that is on the shut-off assembly and a shut-off service kit is more appropriate.

My NL400 will not build pressure. Will installing this kit solve it?

Very often, yes, because worn O-rings and check valves are top causes of “no pressure” complaints. If you still cannot hold pressure after the swap, re-check for debris in the check valve and make sure the suction is fully submerged to avoid cavitation.

What pressure should the NL400 reach once it is healthy?

The NL400 platform is specified with an internal piston pump up to 150 pounds per square inch. Good seals help you reach and hold that figure again.

Which lubricant should I use on the new O-rings?

Follow the manufacturer first. Smith documents for many of its pump sprayers say to lubricate O-rings with petroleum jelly, except where the model specifically calls for silicone grease such as acetone-rated units. If you are unsure, a small amount of pure silicone O-ring grease is widely recommended in industry guides and plays nice with most elastomers. Always keep the film light to avoid swelling.

Are Viton seals really more chemical-resistant?

Viton (FKM) is selected exactly for that reason. Compatibility charts show strong performance across many pesticides and solvents. Always confirm your exact formulation against a compatibility chart and the pesticide label.

How often should I replace seals or the check valve?

Smith’s care guides advise cleaning and lubricating O-rings at least once per season, more often with heavy use. Many professional shops also replace backpack check valves on a preventive schedule because a tired or dirty check valve is a common source of pressure loss.

Can I use bleach or strong cleaners with these seals?

Viton holds up well to many oxidizers, oils, and solvents, but compatibility depends on concentration and temperature. Check a Viton compatibility guide and your chemical’s label before use. If you routinely run high-strength oxidizers, expect more frequent inspections of seals regardless of material.

Where can I see a parts diagram and service steps for the NL400 family?

The NL403/NL400 Use & Care Manual shows the servicing sequence, the note that Kit #32 contains the primary seals and gaskets, and the troubleshooting table. It also lists the manufacturer’s support line and hours.

Will this kit work on other brands like Field King or Roundup No-Leak backpacks?

Use the kit that is listed for your exact model. The 182656 kit is specified for Smith NL400-series sprayers. Field King and Roundup No Leak models are made by the same parent company, however their kits use different part numbers.

I replaced seals, but the sprayer still weeps at the trigger. What next?

That points to the shut-off valve rather than the pump. Smith sells shut-off service kits and complete shut-off assemblies with Viton seals. Look up your shut-off model number to match parts.

Can the NL400 spray wettable powders after a seal refresh?

Yes. The product page states the NL400 can be used with wettable powders and liquids. A healthy seal set and clean agitation system help keep powders in suspension and the pattern crisp.

Conclusion

If your NL400-series backpack sprayer is losing prime, spitting at the tip, or weeping at the pump mount, the Backpack Sprayer Seal Gasket Kit 182656 targets the exact wear points that cause those symptoms. It is the factory Viton pump service kit for the NL400, NL401, NL402, and NL403 models, and the service manual even calls out that the parts required to service the primary seals and gaskets are bundled as Kit 32. Restoring those seals lets the internal piston pump return to its design behavior, including the platform’s ability to push up to 150 psi for a crisp, consistent pattern.

This is not a generic rubber assortment. The kit is specified by the Fountainhead Group for the NL400 family, and it uses Viton where chemical resistance and compression-set performance matter. Chemours, the Viton brand owner, provides a searchable chemical-resistance guide that helps you verify your exact active ingredient and carrier before you spray. That combination of manufacturer fit and material data is why this repair lasts.

Related products

-

Sale!

23.6 inch Battery Powered Sprayer Wand with Telescopic Lance

$30.00Original price was: $30.00.$26.99Current price is: $26.99. Buy Now -

SOLO 315-A Backpack Sprayer: 4-Gallon Viton(R) G7915559

$134.99 Buy Now -

Sale!

Chapin 63924 4-Gallon 24V Battery Backpack Sprayer With Adjustable Brass Nozzle

$218.99Original price was: $218.99.$204.99Current price is: $204.99. Buy Now -

Sale!

VaxMay 4 Gallon Battery Backpack Sprayer, Makita 18V Compatible

$94.99Original price was: $94.99.$85.49Current price is: $85.49. Buy Now

Reviews

There are no reviews yet.